What Potential Hazards are Associated with 3D Printing? How to Prevent?

Date: 2021-01-22

Keywords: What,Potential,Hazards,are,Associated,with,Printing,How,

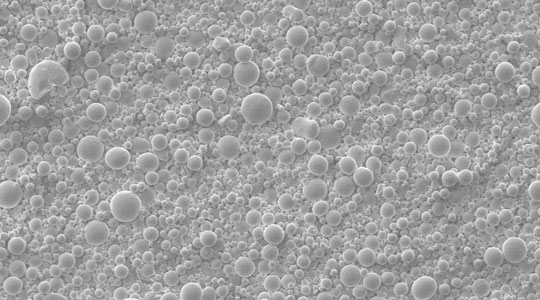

Abstract: So, what are the potential hazards of 3D printing? How should we prevent it? According to NIOSH related documents, we can find these potential hazards in 3D printing:Potential hazards may include:• Breathing and skin contact with volatile organic chemicals (VOCs) and particulates (printing) and other chemicals (post-printing) • Hot surfaces and moving parts

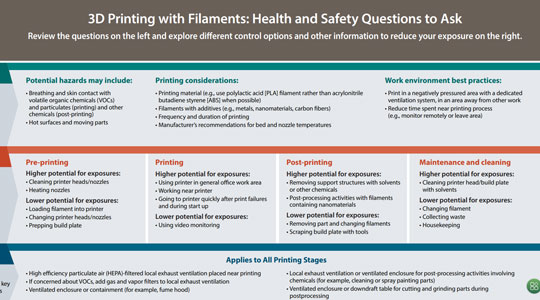

3D Printing with Filaments: Health and Safety Questions to Ask

Date: 2021-01-22

Keywords: Printing,with,Filaments,Health,and,Safety,Questions,Ask,

Abstract: What potential hazards are associated with 3D printing? Are there known health effects from the filaments (for example, see safety data sheets)? What is the work environment like (for example, open or isolated area)?

Titanium Dioxide Sputtering Target (TiO2) Video

Date: 2021-01-22

Keywords: Titanium,Dioxide,Sputtering,Target,TiO2,Video,Titanium,

Abstract: TiO2 Sputtering Target. Brand: AEM Deposition. Purity: 99.99%. Diameter: Φ40 x 50 mm. Application:• Decorative coating. • Flat Panel Displays. • Low-E Glass industry

Fe2O3 doped HfO2 Sputtering Target Video

Date: 2021-01-22

Keywords: Fe2O3,doped,HfO2,Sputtering,Target,Video,Fe2O3,doped,HfO2,

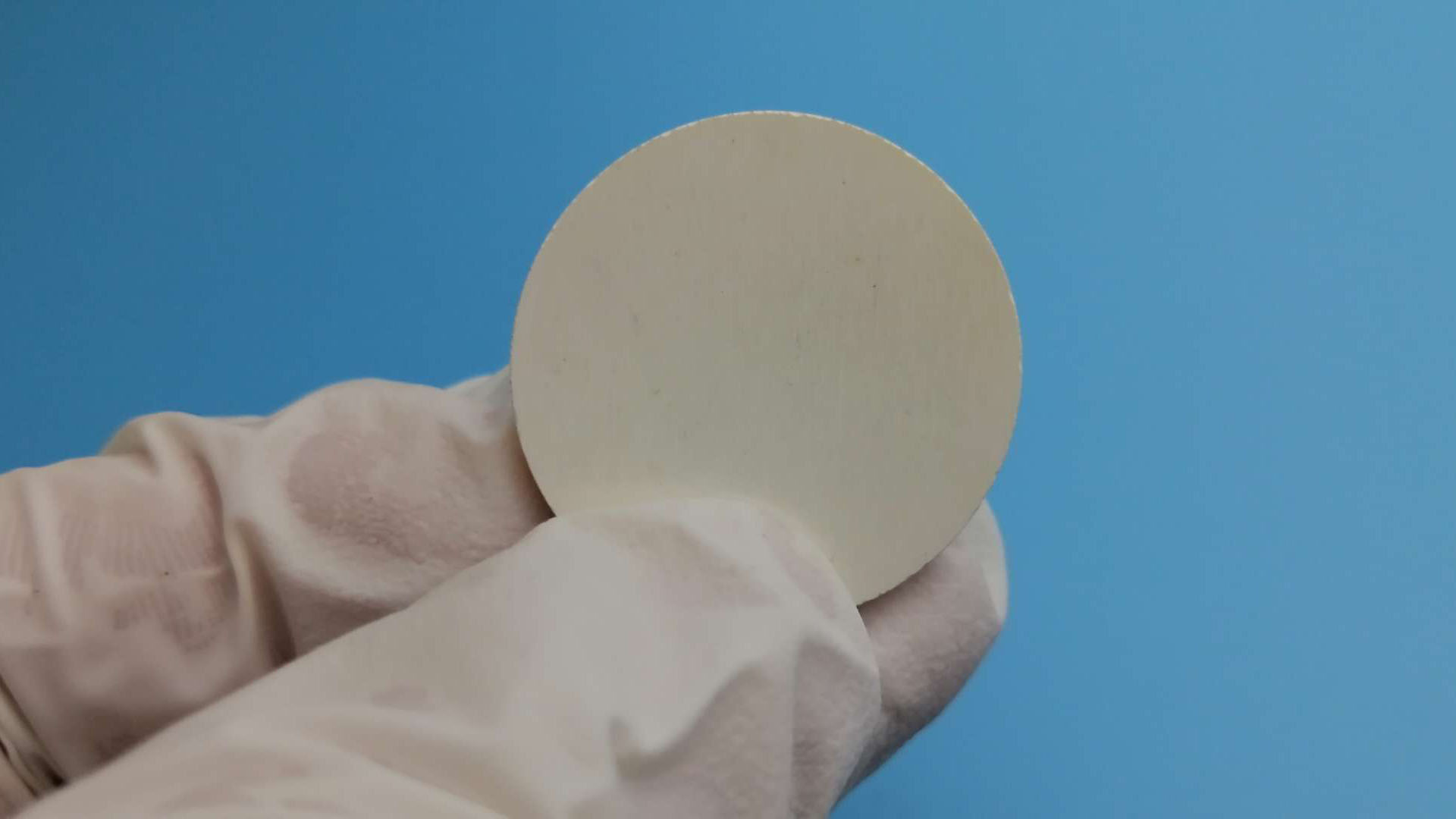

Abstract: Fe2O3 doped HfO2 Sputtering Target. 6.0 at% Fe2O3 doped HfO2. Brand: AEM Deposition. Purity: 99.95%. Diameter: 1 inch. Thickness: 0.125 inch

HfO2 doped Ta2O5 Sputtering Target Video

Date: 2021-01-22

Keywords: HfO2,doped,Ta2O5,Sputtering,Target,Video,HfO2,doped,Ta2O5,

Abstract: HfO2 doped Ta2O5 Sputtering Target. 6.0 at% HfO2 doped Ta2O5. Brand: AEM Deposition. Purity: 99.95%. Diameter: 1 inch. Thickness: 0.125 inch

Ta2O5 doped HfO2 Sputtering Target Video

Date: 2021-01-22

Keywords: Ta2O5,doped,HfO2,Sputtering,Target,Video,Ta2O5,doped,HfO2,

Abstract: Ta2O5 doped HfO2 Sputtering Target. 6.0 at% Ta2O5 doped HfO2. Brand: AEM Deposition. Purity: 99.95%. Diameter: 1 inch.Thickness: 0.125 inch

Y2O3 doped HfO2 Sputtering Target Video

Date: 2021-01-22

Keywords: Y2O3,doped,HfO2,Sputtering,Target,Video,Y2O3,doped,HfO2,

Abstract: Y2O3 doped HfO2 Sputtering Target. 6.0 at% Y2O3 doped HfO2. Brand: AEM Deposition. Purity: 99.95%. Diameter: 1 inch Thickness: 0.125 inch

Tungsten Sputtering Target (W) Video

Date: 2021-01-22

Keywords: Tungsten,Sputtering,Target,Video,Tungsten,Sputtering,Target,

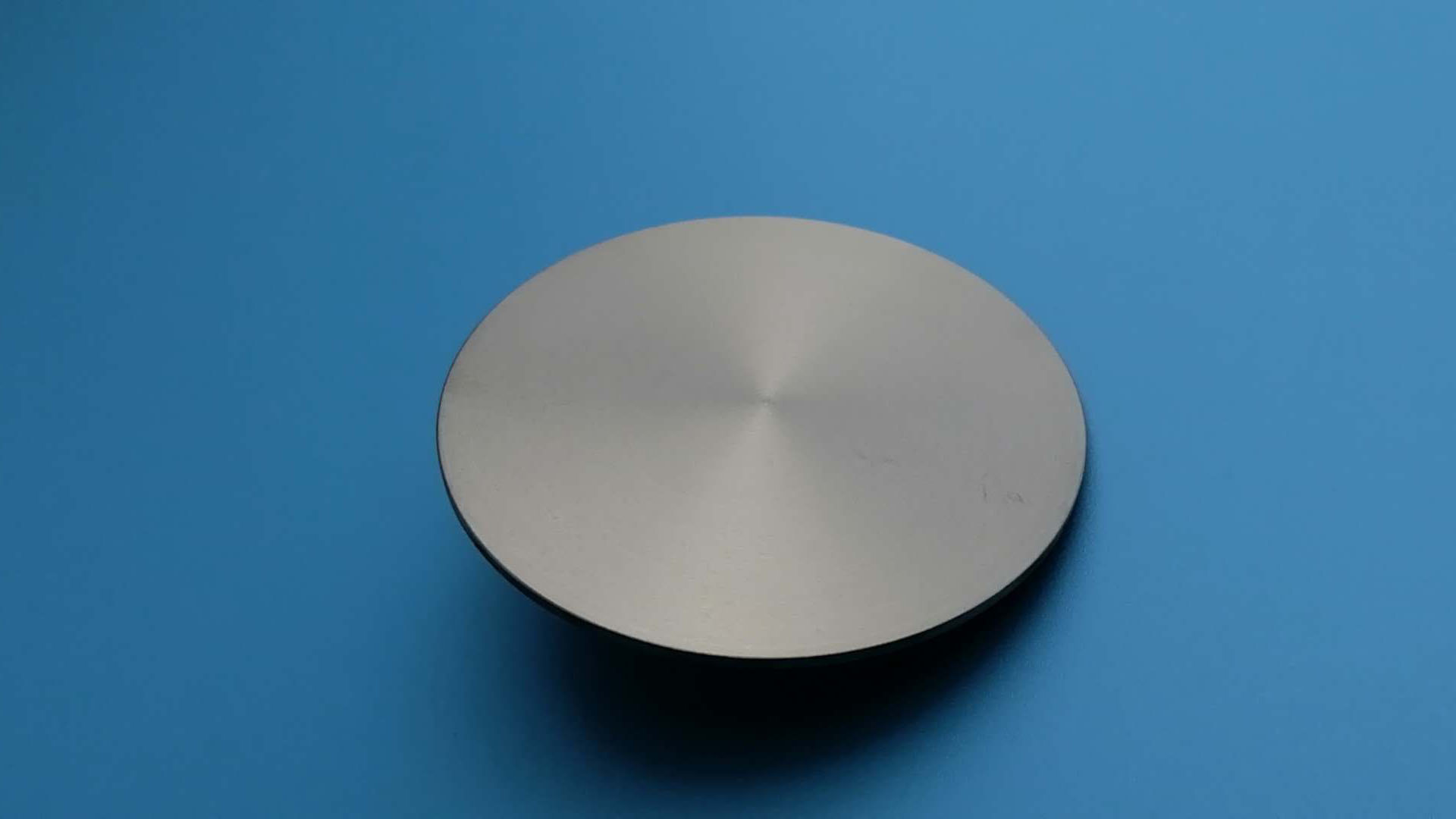

Abstract: Tungsten Sputtering Target. Brand: AEM Deposition. Purity: 99.95%. Diameter: 57 mm. Thickness: 1.5 mm

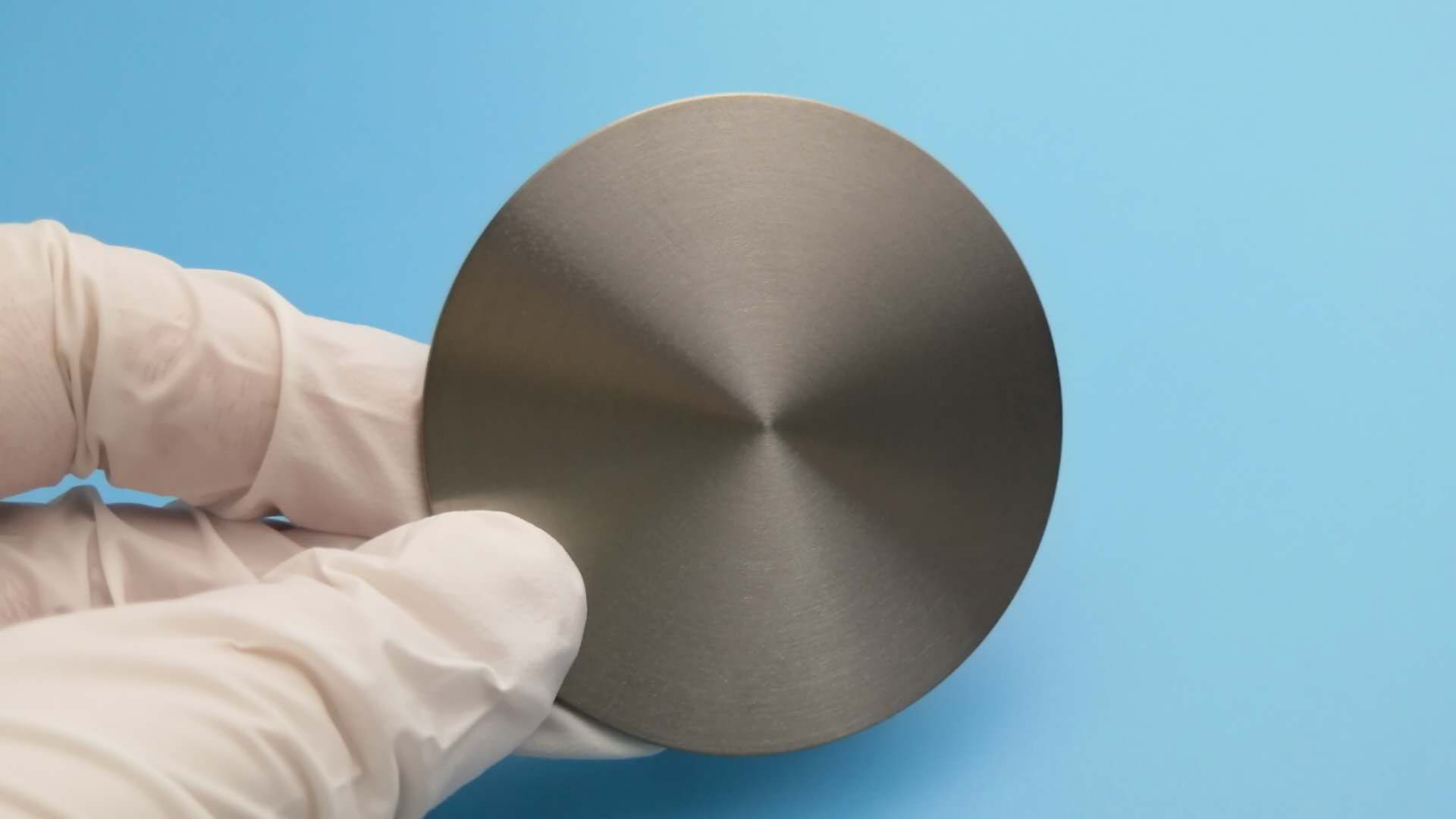

Titanium Sputtering Target (Ti) Video

Date: 2021-01-22

Keywords: Titanium,Sputtering,Target,Video,Titanium,Sputtering,Target,

Abstract: Titanium Sputtering Target. Brand: AEM Deposition. Purity: 99.995%. Diameter: 57 mm. Thickness: 1.5 mm

Tantalum Sputtering Target (Ta) Video

Date: 2021-01-22

Keywords: Tantalum,Sputtering,Target,Video,Tantalum,Sputtering,Target,

Abstract: Tantalum Sputtering Target. Brand: AEM Deposition. Purity: 99.95%. Diameter: 57 mm. Thickness: 0.1 mm

ITO Sputtering Target (Indium Tin Oxide) Video

Date: 2021-01-22

Keywords: ITO Sputtering Target

Abstract: ITO Sputtering Target (In2O3/SnO2 90/10 wt%) .Brand: AEM Deposition. Purity: 99.99%. Density: 7.13g/cm3. Size: 200mm x 65mm x 6mm. Indium bonded to a 200mm x 65mm x 1.6mm Cu backing plate.

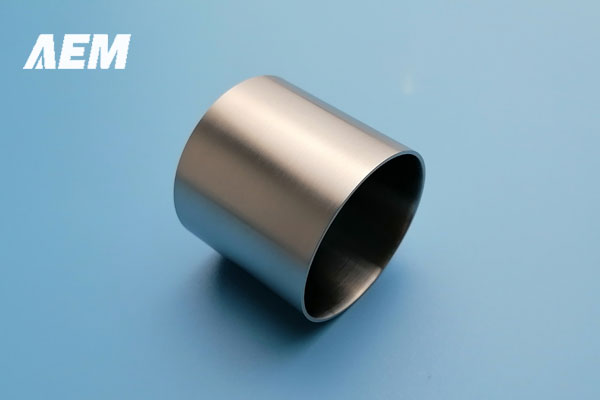

Molybdenum Crucible (Mo) Video

Date: 2021-01-22

Keywords: Molybdenum,Crucible,Video,

Abstract: Molybdenum Crucible: Purity: 99.5%~99.99%; Surface: Finish turning, polishing; Density: 10.10 g/cm3; Melting Point: 2630℃. Application: Laboratory uses, metallurgy industry, mechanism process industry, crystalloid materials, and other burgeoning high technology industry.