Your Essential Guide to Semiconductor Materials: From Silicon to Gallium and Germanium

Date: 2025-06-20

Abstract: Explore key semiconductor materials and their uses in tech, solar, EVs & more. Learn what makes each one essential.

Silicon Monoxide Sputtering Targets Video

Date: 2023-10-17

Abstract: Explore our SiO Sputtering Target Video - 99.9% Purity | Size: ø 42x6mm. Discover the perfect composition for your sputtering needs.

Magnesium Oxide Sputtering Target Video

Date: 2023-10-17

Abstract: Watch our Delta-Shaped MgO Sputtering Targets Video - 99.9% Purity | 0.375-Inch Thickness. Explore premium materials for sputtering applications.

Sputtering Targets Overview: Everything You Need to Know

Date: 2024-07-01

Abstract: Sputtering targets are made of various materials depending on their purpose. This guide covers everything you need to know, like the types and how to choose.

Tungsten Evaporation Boats Video

Date: 2023-07-26

Abstract: If you're looking for a reliable and efficient evaporation boat, look no further than our Tungsten Evaporation Boats.

Evaporation Deposition Guide: Processes, Types, and Materials

Date: 2025-06-20

Abstract: Learn the essentials of evaporation deposition with expert tips for material buyers—covering processes, materials, techniques, and applications.

Sputter Coating Explained: Key Benefits, Applications & Target Solutions

Date: 2025-06-20

Abstract: Learn what sputter coating is, how it works, key benefits, and how AEM Deposition provides high-quality sputtering targets for advanced thin-film coatings.

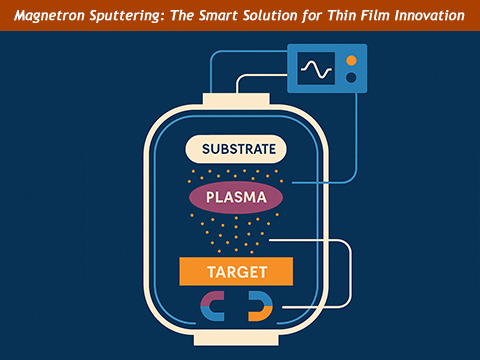

Magnetron Sputtering: The Smart Solution for Thin Film Innovation

Date: 2025-05-09

Abstract: Discover what magnetron sputtering is and why AEM Deposition is the trusted global supplier for magnetron sputtering targets.

Understanding Physical Vapor Deposition: The Key to Advanced Coatings

Date: 2025-04-09

Abstract: Learn how Physical Vapor Deposition provides durable, precise coatings. Discover benefits, applications, and quality sputtering targets at AEM Deposition.

Comprehensive Guide to Transparent Conducting Oxides (TCOs)

Date: 2025-02-28

Abstract: Understanding Transparent Conducting Oxides (TCOs) and how AEM Deposition's sputtering targets deliver superior performance.

Top 10 Silicon Wafer Manufacturers You Should Know

Date: 2024-10-24

Abstract: Find the outstanding silicon wafer suppliers worldwide. Detailed profiles of the top 10 manufacturers driving the semiconductor industry forward.

Top Custom Sputtering Target Manufacturers & Brands List

Date: 2024-09-10

Abstract: Discover the best sputtering target manufacturers now. Find your ideal supplier from our curated list today!

Understanding the Difference: N-Type vs P-Type Semiconductors

Date: 2023-08-04

Abstract: Do you know what sets N-Type and P-Type Semiconductors apart? This article will delve into these two types of semiconductors to help you understand their differences.

Preparation of Ultrafine Metal Powder by Air Flow Milling

Date: 2021-09-29

Abstract: Ultrafine metal powder can be prepared by mechanical method and physical methods. Today, check the preparation method of ultra-fine metal powder.

Preparation of Ultrafine Metal Powder by Ball Milling

Date: 2021-09-29

Abstract: Ultrafine metal powder materials can be widely used in aerospace, ship, automobile, metallurgy, chemical industry, and other fields.