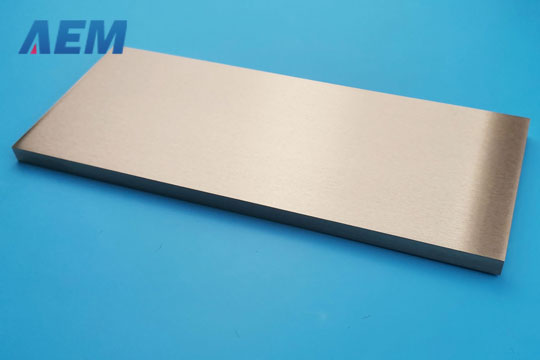

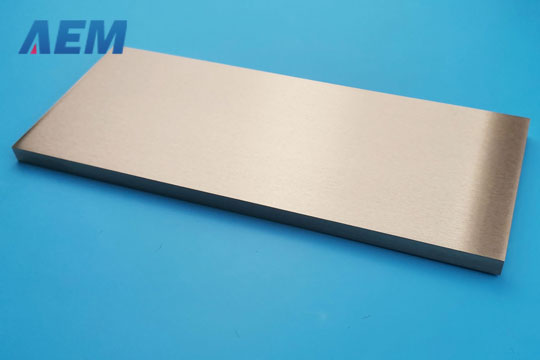

Aluminum Sputtering Targets (Al)

Purity: 99.999%

Size: 2" diameter x 0.25" thickness

Price: $60/pc

Chromium Sputtering Targets (Cr)

Purity: 99.95%

Size: 2" diameter x 0.25" thickness

Price: $70/pc

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

Most ceramic targets benefit from being bonded to a backing plate to increase target cooling. Also, the target must be conditioned before depositing films from it.

To avoid oxidation, lithium should be kept either in oil or an inert argon atmosphere. Unused pieces should be repackaged in the oil with a tight seal and stored in a cool.

Our webpages for sputtering targets have bonding recommendations. Please visit the products menu for the required target, and all the recommendations are stated there.

Our recommendation is to fill the crucible between ⅔ and ¾ full. We find that the melting point of a material in the crucible directly affects the crucible liner.

The thickness of the wafers is always determined by the automated strength of the used materials, which means the wafer should be thick enough to not crack during handling.