Sizen Limited (brand name is AEM) is an international company involved in research and development, manufacturing, and sales of all varieties of high-tech materials. We offer high purity non-ferrous materials, customized alloys, compounds, and almost every type of complicated synthetic materials to worldwide research institutes and high-tech enterprises. We have a complete machining center, and we do all of our machining "In House" to ensure strict adherence to our mechanical specifications. And we provide a part of equipment for materials processing or testing to prove our strength.

Suspension Melting Furnace

Intermediate Frequency Anneal Furnace

Arc Melting Furnaces

Carbon Tube Furnace

High Vacuum Carbon Tube Furnace

Vacuum Hot-pressing Furnace

Dehydrogenation Furnace

Intermediate Frequency Anneal Furnace

CNC

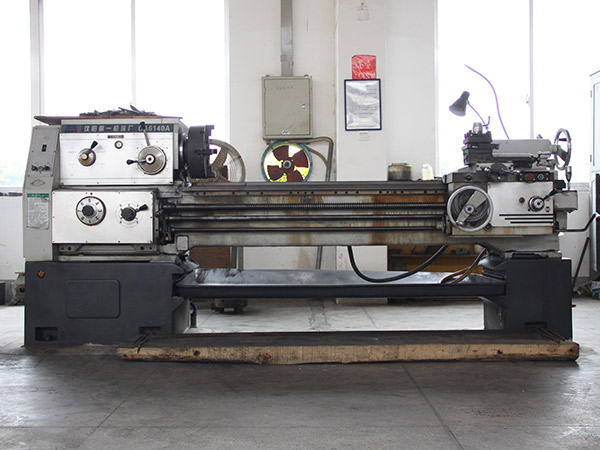

Lathe

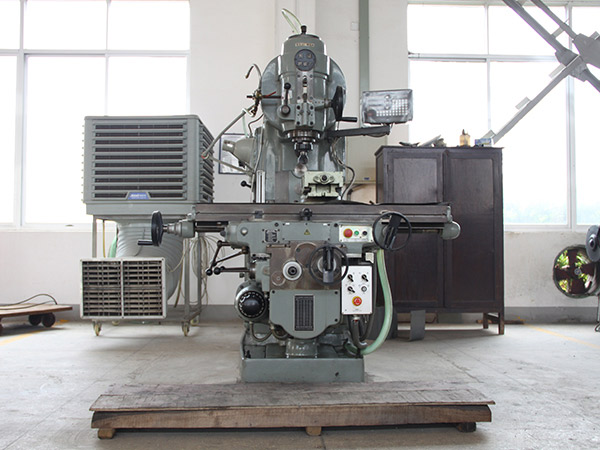

Milling Machine

Hydraulic Machine

Wire Electrical Discharge Machining (WEDM)

Workshop

American Agilent Atomic Absorption Spectrophotometer

French JY Inductively Coupled Plasma Emission Spectrometer

Inductively Coupled Plasma Mass Spectrometry (ICP)

Delivery

AEM strives to deliver all orders within the timeframe referenced on the original quotation (Regular delivery time is 2 to 3 weeks). However, if your order has the possibility to be delayed, AEM will contact you with an updated schedule.

Packaging

Upon completion, our quality control specialists give the final inspection to all products. Then products are thoroughly cleansed and packaged in our air-controlled cleanroom under vacuum seal in a 5-millimeter poly bag.

Documentation

All products shipped are properly labeled and contain the appropriate documentation, which includes, but is not limited to, a Certificate of Analysis, Material Safety Data Sheet, and the Packing List. Custom documentation is available upon request.

Confidentiality

We routinely sign non-disclosure agreements to protect customers' proprietary process information.