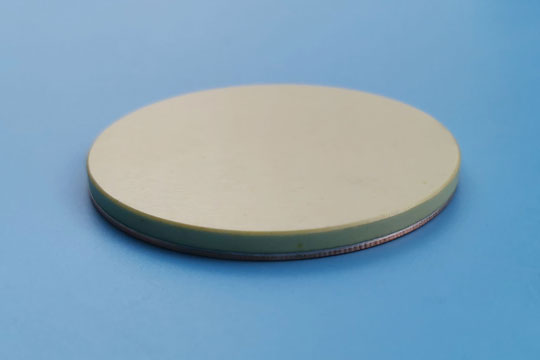

Zinc Oxide Sputtering Target Video

Date: 2021-01-22

Keywords: Zinc,Oxide,Sputtering,Target,Video,Zinc,Oxide,Sputtering,

Abstract: Zinc Oxide Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: Φ57 x 3 mm.Indium bonding to copper back plate

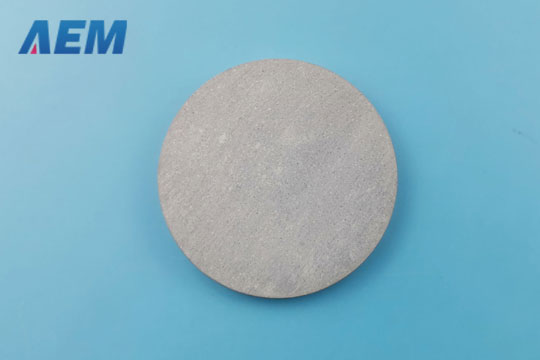

Pr0.7Ca0.3MnO3 Sputtering Target Video

Date: 2021-01-22

Keywords: Pr0.7Ca0.3MnO3,Sputtering,Target,Video,Pr0.7Ca0.3MnO3,

Abstract: Pr0.7Ca0.3MnO3 Sputtering Target.Brand: AEM Deposition.Purity: 3N 99.9%.Size: Φ59.8 x 3/3 mm

(La0.6Sr0.4)Co1.8Ox Sputtering Target Video

Date: 2021-01-22

Keywords: La0.6Sr0.4,Co1.8Ox,Sputtering,Target,Video,La0.6Sr0.4,

Abstract: (La0.6Sr0.4)Co1.8Ox Sputtering Target.Brand: AEM Deposition.Purity: 4N 99.99%.Size: Φ50.8 x 3.2/3 mm

LiFePO4 Sputtering Target Video

Date: 2021-01-22

Keywords: LiFePO4,Sputtering,Target,Video,LiFePO4,Sputtering,Target,

Abstract: LiFePO4 Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: Φ2'' x 0.125''.

Intermetallic Crucible (BN-TiB2) Video

Date: 2021-01-22

Keywords: Intermetallic,Crucible,BN-TiB2,Video,Intermetallic,Crucible,

Abstract: Intermetallic Crucible (BN-TiB2) .Brand: AEM Deposition. Top OD : 20.8 mm. Bottom OD : 11.5 mm. Height: 15.5 mm.Wall thickness: 2 mm

Alumina Crucible (Al2O3) Video

Date: 2021-01-22

Keywords: Alumina,Crucible,Al2O3,Video,Alumina,Crucible,https,

Abstract: Alumina Crucible (Al2O3) .Brand: AEM Deposition .Top OD: 22.6 mm. Bottom OD: 14.23 mm. Height: 15.0 mm.Wall thickness: 2.25 mm

Tungsten Crucible Video

Date: 2021-01-22

Keywords: Tungsten,Crucible,Video,Tungsten,Crucible,https,

Abstract: Tungsten (W) Crucible.Brand: AEM Deposition.Volume: 7cc-6pkt.Liner Volume: 3.4cc.Top OD: 1.125" Height: 0.52". Wall Thickness: 0.09" Angle: 15º

MoO3 Sputtering Target Video

Date: 2021-01-22

Keywords: MoO3,Sputtering,Target,Video,MoO3,Sputtering,Target,https,

Abstract: MoO3 Sputtering Target. Brand: AEM Deposition.Purity: 99.95%. Size: Dia 2" x Thick 0.125'' .Indium bonding to Cu backing plate.Tolerance: ± 0.1 mm

LCO (LiCoO2) Sputtering Target Video

Date: 2021-01-22

Keywords: LCO,LiCoO2,Sputtering,Target,Video,LCO,LiCoO2,Sputtering,

Abstract: LCO (LiCoO2) Sputtering Target.Brand: AEM Deposition.CAS #: 12190-79-3. Purity: 99.9%. Size: Dia 2" x Thick 0.25" Single phase product.

NMC Sputtering Target (LiNi0.33Mn0.33Co0.33O2) Video

Date: 2021-01-22

Keywords: NMC,Sputtering,Target,LiNi0.33Mn0.33Co0.33O2,Video,NMC,

Abstract: NMC Sputtering Target.LiNi0.33Mn0.33Co0.33O2.Brand: AEM Deposition.CAS #: 346417-97-8.Purity: 99.9%.Size: Dia 2" x Thick 0.25".Single phase product

ITO Sputtering Target Video

Date: 2021-01-22

Keywords: ITO,Sputtering,Target,Video,ITO,Sputtering,Target,https,

Abstract: ITO Sputtering Target.In2O3/SnO2 90/10 wt%.Brand: AEM Deposition.Purity: 99.99%. Size: Dia 2" x Thick 0.25".Tolerance: ±0.1 mm

Zirconium Sputtering Target (Zr) Video

Date: 2021-01-22

Keywords: Zirconium,Sputtering,Target,Video,Zirconium,Sputtering,

Abstract: Zirconium Sputtering Target. Brand: AEM Deposition. Purity: 99.95%. Size: 2" diameter x 0.25" thickness. Tolerance: ± 0.1 mm.