Silicon Sputtering Target Video

Date: 2021-01-22

Keywords: Silicon,Sputtering,Target,Video,Silicon,Sputtering,Target,

Abstract: Silicon Sputtering Target.Brand: AEM Deposition.Type: Monocrystalline.Purity: 99.999%. Size: Φ8'' x 0.25''.Tolerance: ±0.01" on all the dimensions.

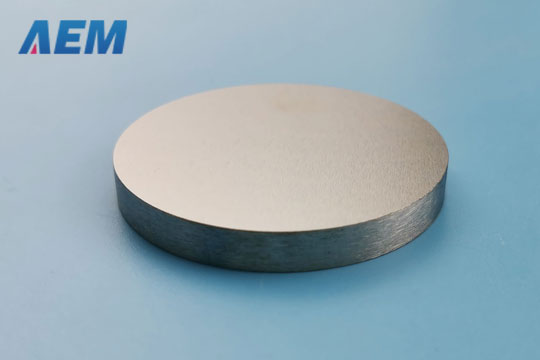

Hafnium Sputtering Target Video

Date: 2021-01-22

Keywords: Hafnium,Sputtering,Target,Video,Hafnium,Sputtering,Target,

Abstract: Hafnium Sputtering Target.Brand: AEM Deposition. Purity: Zr+Hf ≥99.95%. Size: Φ 8'' x 0.25''.Tolerance: ±0.01" on all the dimensions.

Ytterbium Oxide Sputtering Target Video

Date: 2021-01-22

Keywords: Ytterbium,Oxide,Sputtering,Target,Video,Ytterbium,Oxide,

Abstract: Yb2O3 Sputtering Target.Brand: AEM Deposition.Size: Φ3'' x 0.125''

Boron Nitride Boat Video

Date: 2021-01-22

Keywords: Boron,Nitride,Boat,Video,Boron,Nitride,Boat,https,

Abstract: Boron Nitride Boat (BN).Brand: AEM Deposition.Purity: 99.7%.L x W x H: 110 x 6.0 x 4.0 mm.Cavity size: L x W x H 40 x 4.0 x 2.0 mm

Lithium Niobate Sputtering Target Video

Date: 2021-01-22

Keywords: Lithium,Niobate,Sputtering,Target,Video,LiNbO3,Sputtering,

Abstract: LiNbO3 Sputtering Target.Brand: AEM Deposition.Purity: 3N5 99.5%.Size: Φ50.8mm x 3.2/3 mm

Lithium Phosphate Sputtering Target Video

Date: 2021-01-22

Keywords: Lithium,Phosphate,Sputtering,Target,Video,Li3PO4,Sputtering,

Abstract: Li3PO4 Sputtering Target.Brand: AEM Deposition.Purity: 4N 99.99%.Size: Φ50.8mm x 3.2/3 mm

Hafnium Oxide Sputtering Target Video

Date: 2021-01-22

Keywords: Hafnium,Oxide,Sputtering,Target,Video,HfO2,Sputtering,

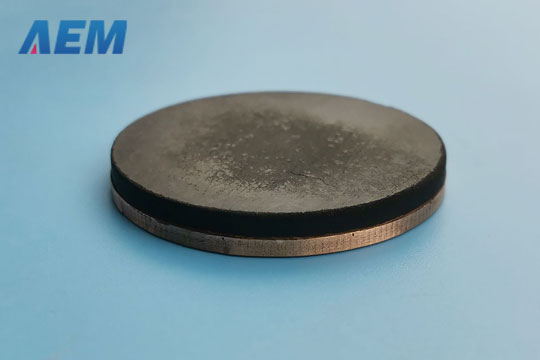

Abstract: HfO2 Sputtering Target. Brand: AEM Deposition. Purity: 99.95%.Size: Φ2'' x 0.25''

Titanium Nitride Sputtering Target Video

Date: 2021-01-22

Keywords: Titanium,Nitride,Sputtering,Target,Video,Titanium,Nitride,

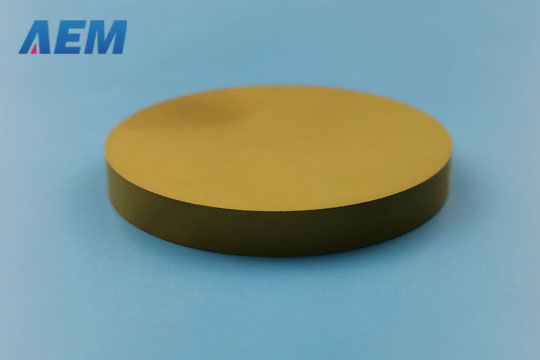

Abstract: TiN Sputtering Target.Brand: AEM Deposition.Purity: 99.5%.Size: Φ2'' x 0.25''

Li1.5(Ni0.6Co0.2Mn0.2)O2 Sputtering Target Video

Date: 2021-01-22

Keywords: Li1.5,Ni0.6Co0.2Mn0.2,Sputtering,Target,Video,Li1.5,

Abstract: Li1.5(Ni0.6Co0.2Mn0.2)O2 Sputter Target.Brand: AEM Deposition.Purity: 3N 99.9%.Size: Φ50.8 x 3.2/3 mm

Barium Zirconate Sputtering Target Video

Date: 2021-01-22

Keywords: Barium,Zirconate,Sputtering,Target,Video,Barium,Zirconate,

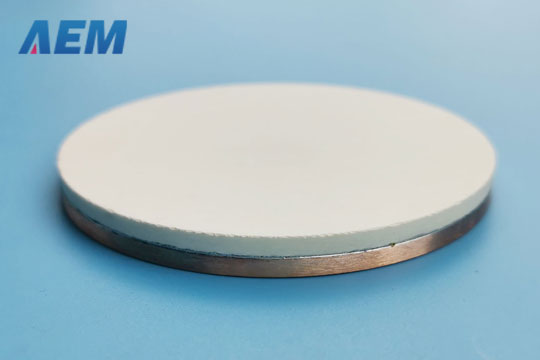

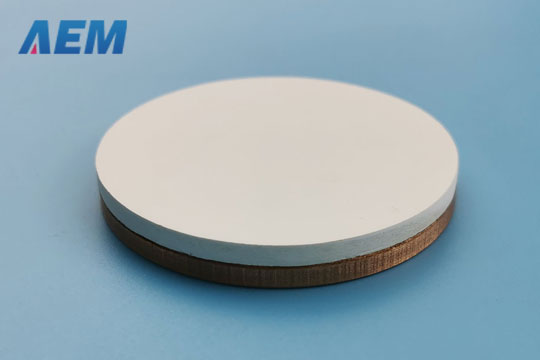

Abstract: BaZrO3 Sputtering Target.Brand: AEM Deposition.Purity: 99.5%.Size: Φ2'' x 0.125'' + Cu

Nickel Titanium Sputtering Target Video

Date: 2021-01-22

Keywords: Nickel,Titanium,Sputtering,Target,Video,Nickel,Titanium,

Abstract: Nickel Titanium Sputtering Target.Brand: AEM Deposition.Composition: Ni/Ti 50/50wt%. Size: Φ50.8 mm x 6.35 mm

Copper Zirconium Sputtering Target Video

Date: 2021-01-22

Keywords: Copper,Zirconium,Sputtering,Target,Video,Copper,Zirconium,

Abstract: Copper Zirconium Sputtering Target.Brand: AEM Deposition Composition: Cu/Zr 36/64 at% .Purity: 99.95% .Size: Φ1" x 5 mm