Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

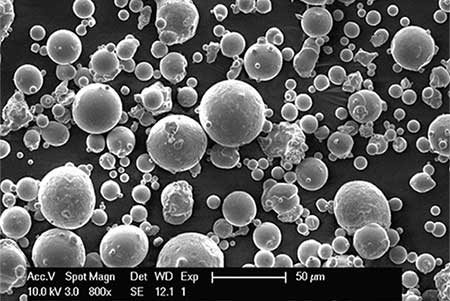

High speed steel is widely used as a tool manufacturing material. High speed steels are alloys that gain their properties from either Tungsten or Molybdenum, often with a combination of the two. They belong to the Fe-C-X multicomponent alloy system where X represents Chromium, Molybdenum, Vanadium, or Cobalt. Because of the segregation problem, the hardness and toughness of traditional cast high speed steel made by hot isocratic pressing (HIP) and powder metallurgy (PM) are improved simultaneously, the servise life of the tool is increased, and the properties of the product are improved. The following table is our high-speed powder.

High speed steel is widely used as a tool manufacturing material. High speed steels are alloys that gain their properties from either Tungsten or Molybdenum, often with a combination of the two. They belong to the Fe-C-X multicomponent alloy system where X represents Chromium, Molybdenum, Vanadium, or Cobalt. Because of the segregation problem, the hardness and toughness of traditional cast high speed steel made by hot isocratic pressing (HIP) and powder metallurgy (PM) are improved simultaneously, the servise life of the tool is increased, and the properties of the product are improved. The following table is our high-speed powder.

| Grade | Chemical Composition (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Fe | Ni | Mo | Co | V | Si | Al | Cu | Mn | ||

| DT-4/Ingot Iron | ≤0.03 | ≥99.75 | |||||||||

| Si6.5Fe/X-Flux | ≤0.03 | Bal. | 6.5-8.5(adjustable) | ||||||||

| 1J50/Hyperm52 | ≤0.03 | Bal. | 49.0-50.0 | 0.15-0.3 | ≤0.2 | 0.3-0.6 | |||||

| 1J22/Permendur | ≤0.04 | Bal. | ≥0.5 | 49-51 | 0.8-1.8 | ≤0.3 | ≤0.2 | ≤0.5 | |||

| 1J1/SENDUST | ≤0.03 | Bal. | 8.0-10.0 | 4.5-7.5 | |||||||

| 1J79/Mo-Permalloy | ≤0.03 | Bal. | 78.5-80.0 | 3.8-4.1 | 0.3-0.5 | ≤0.2 | 0.6-1.1 | ||||