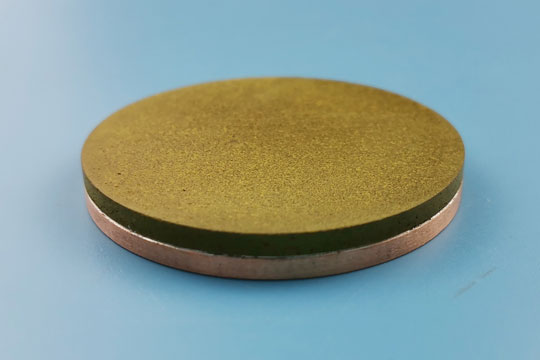

Indium Selenide Sputtering Target Video

Date: 2021-09-07

Abstract: In2Se3 Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: Φ 2" x 2.0 mm.Indium bonding to a Cu backing plate

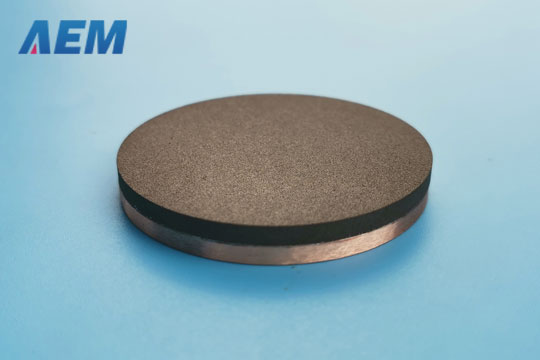

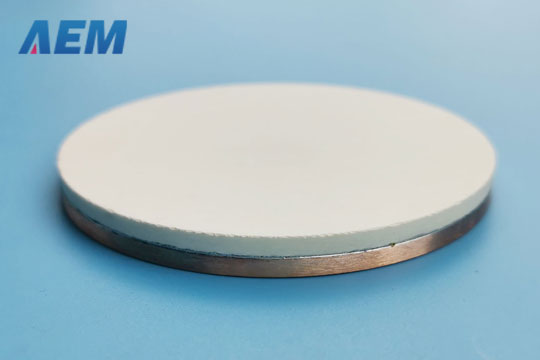

Titanium Disilicide Sputtering Target Video

Date: 2022-09-08

Abstract: TiSi2 Sputtering Target.Brand: AEM Deposition.Purity: 99.5%. Size: Φ2" x 0.125" + Cu

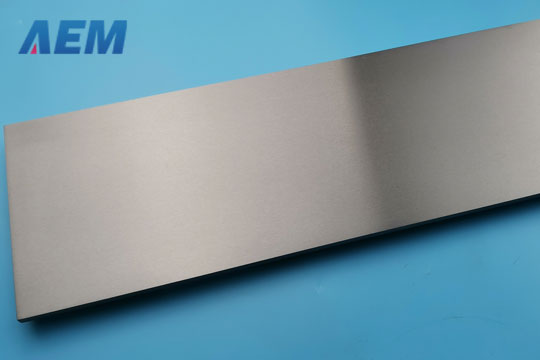

Tantalum Sputtering Target Video

Date: 2021-09-09

Abstract: Tantalum (Ta) Sputtering Target. Purity: 99.95%. Size: 450 mm x 150 mm x 8 mm. Tolerance: ± 0.1" on all the dimensions

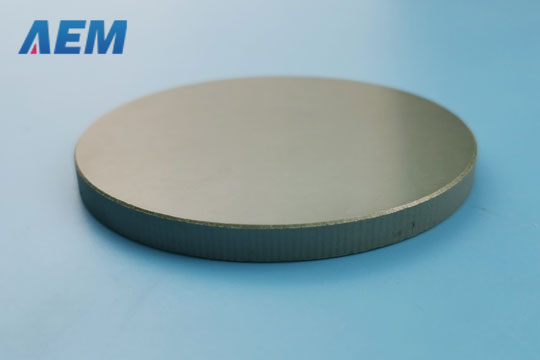

GZO Sputtering Target Video

Date: 2021-09-09

Abstract: GZO Sputtering Target. Brand: AEM Deposition. Purity: 99.99%. Size: Φ76.2 x 6.35 mm

Silicon Dioxide Evaporation Material Video

Date: 2021-09-09

Abstract: Silicon Dioxide Pellet.Brand: AEM Deposition. Size: 2-4 mm.Applications: - Used in structural materials; - Microelectronics; - As components in the food and pharmaceutical industries.

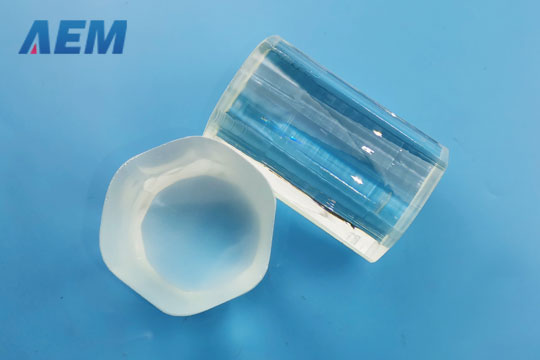

Yttrium Aluminium Garnet (YAG) Crystal Video

Date: 2021-09-09

Abstract: Yttrium Aluminium Garnet (YAG) Crystal,Brand: AEM Deposition, Orientation: 111,Size: 60 mm diameter x 95 mm length

LiNiVO4 Sputtering Target Video

Date: 2021-09-08

Abstract: LiNiVO4 Sputtering Target. Brand: AEM Deposition. Purity: 3N, 99.9%.Size: Φ50.8 x 3 / Φ50.8 x 3 mm

Aluminum Sputtering Target Video

Date: 2021-09-08

Abstract: Aluminum (Al) Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: Φ8'' x 0.25''.Tolerance: ±0.01" on all the dimensions

Titanium Sputtering Target Video

Date: 2021-09-08

Abstract: Titanium (Ti) Sputtering Target.Brand: AEM Deposition. Purity: 99.99%. Size: Φ8'' x 0.25''.Tolerance: ±0.01" on all the dimensions

Silicon Sputtering Target Video

Date: 2021-09-08

Abstract: Silicon Sputtering Target.Brand: AEM Deposition.Type: Monocrystalline.Purity: 99.999%. Size: Φ8'' x 0.25''.Tolerance: ±0.01" on all the dimensions.

Hafnium Sputtering Target Video

Date: 2021-09-09

Abstract: Hafnium Sputtering Target.Brand: AEM Deposition. Purity: Zr+Hf ≥99.95%. Size: Φ 8'' x 0.25''.Tolerance: ±0.01" on all the dimensions.

Ytterbium Oxide Sputtering Target Video

Date: 2021-09-09

Abstract: Yb2O3 Sputtering Target.Brand: AEM Deposition.Size: Φ3'' x 0.125''