Copper Sputtering Target Video

Date: 2021-09-09

Abstract: Copper Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: 250 mm x 100 mm x 10 mm

Tin Zinc Sputtering Target Video (SnZn)

Date: 2021-09-15

Abstract: Tin Zinc Sputtering Target. Brand: AEM Deposition. Purity: 99.9%. Composition: Sn/Zn 50/50 at%. Size: Dia 3" x THICK 6 mm. Tolerance: ±0.1 mm

Yttrium Hexaboride Sputtering Target Video (YB6)

Date: 2021-09-15

Abstract: Yttrium Hexaboride Sputtering Target. Brand: AEM Deposition. Purity: 99.5%. Size: Dia 2", Thick 6 mm. Tolerance: ± 0.1 mm

Niobium Sputtering Target Video

Date: 2021-09-14

Abstract: Niobium Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2 mm

Niobium Sputtering Target Video

Date: 2021-09-15

Abstract: Niobium Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2 mm

Chromium Sputtering Target Video

Date: 2021-01-22

Abstract: Chromium Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2 mm.

Aluminum Sputtering Target Video

Date: 2021-09-15

Abstract: Aluminum Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2mm

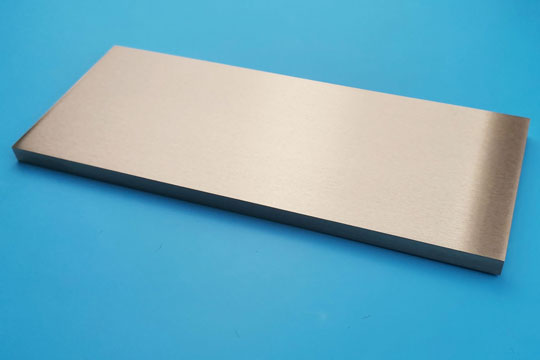

Titanium Sputtering Target Plate Video

Date: 2021-09-15

Abstract: Titanium Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2mm

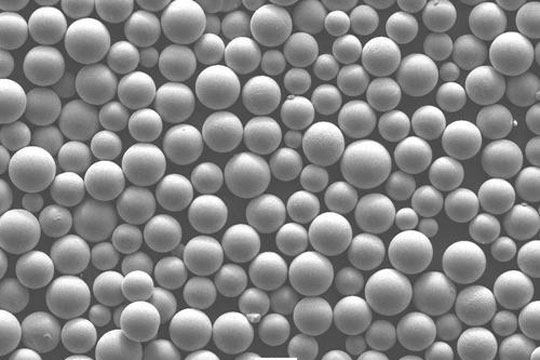

Titanium Powder Preparation by Reduction Method

Date: 2021-09-13

Abstract: At present, the preparation methods of titanium and titanium alloy powder can be divided into the following two types: 1) titanium compound reduction method; 2) titanium raw material crushing or atomization method. In addition, titanium powder needs to be modified to meet the special technological requirements.

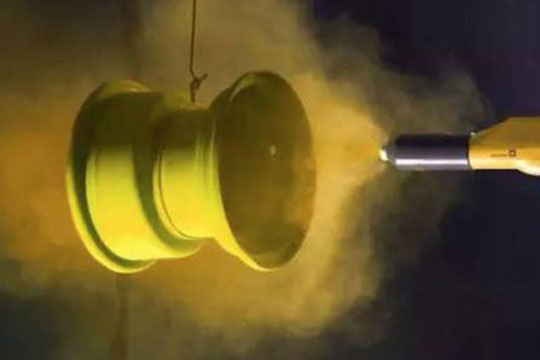

How to Deal with Impurities in the Coating During Electrostatic Powder Spraying?

Date: 2021-09-13

Abstract: Powder electrostatic spraying refers to the electrostatic generator releases high-voltage static electricity (negative electrode) to the space in the direction of the workpiece through the electrode needle at the gun mouth. The high-voltage static electricity ionizes the mixture of powder and compressed air ejected from the gun mouth and the air around the electrode (with negative charge). The powder is driven by electric field and compressed air pressure to the surface of the workpiece, and a uniform coating is formed on the surface of the workpiece by electrostatic attraction. AEM Deposition can provide all kinds of metal powder. The details are as follows:

List of Sputtering Targets for Shield Coating

Date: 2021-09-13

Abstract: Vacuum sputtering EMI has the characteristics of high conductivity and high electromagnetic shielding efficiency. It can be widely used in the EMI shielding of communication products (mobile phones), computers (laptops), portable electronic products, consumer electronics, network hardware (servers, etc.), medical instruments, home electronic products, aerospace and national defense electronic equipment. At the same time, it is suitable for metal shielding of various plastic products (PC, PC + ABS, ABS, etc.).

List of Sputtering Targets for Low Radiation Building Glass

Date: 2021-09-13

Abstract: There are many sputtering targets that can be used for architectural glass coating, such as Ag, Ni / Cr, Sn (SnO2 film), Ti / TiO2 (TiO2 film), Zn (ZnO film), Si / SiAl (SiN film), ZnAl, ZnSn, ZnSnSb, Cr, Nb, Nb2O5 and other sputtering targets, as follows: