Praseodymium Sputtering Targets (Pr)

| Material Type | Praseodymium |

| Symbol | Pr |

| Atomic Weight | 140.90765 |

| Atomic Number | 59 |

| Color/Appearance | Silvery White, Yellowish Tinge, Metallic |

| Thermal Conductivity | 13 W/m.K |

| Melting Point (°C) | 931 |

| Coefficient of Thermal Expansion | 6.7 x 10-6/K |

| Theoretical Density (g/cc) | 6.77 |

| Z Ratio | **1.00 |

| Sputter | DC |

| UN Number | 3208 |

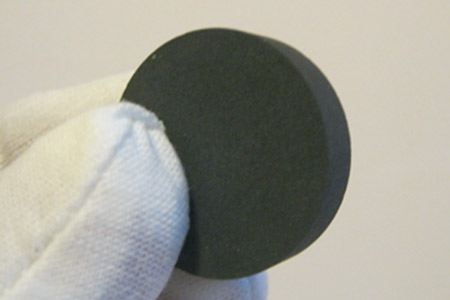

Praseodymium Sputtering Targets

Praseodymium is the third member of the lanthanide series. It exists between the Neodymium and Lanthanides cerium and above the actinide protactinium in the periodic table. It is a ductile metal with a hardness comparable to that of silver. Its 59 electrons are arranged in the configuration [Xe]4f36s2. Theoretically, all five outer electrons can act as valence electrons. However, the use of all five requires extreme conditions. Usually, Praseodymium only gives up three or sometimes four electrons in its compounds. Praseodymium is the first of the lanthanides to have an electron configuration conforming to the Aufbau principle. That predicts the 4f orbitals to have a lower energy level than the 5d orbitals. This does not hold for Lanthanum and Cerium because the sudden contraction of the 4f orbitals does not happen until after Lanthanum and is not strong enough at Cerium to avoid occupying the 5d subshell. Nevertheless, solid Praseodymium takes on the [Xe]4f25d16s2 configuration. One electron in the 5d subshell is like all the other trivalent lanthanides (all but Europium and Ytterbium, which are divalent in the metallic state).

Praseodymium Sputtering Targets Information

Praseodymium Sputtering Targets

Purity: 99.9%;

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm.

Due to these materials' highly reactive nature, packaging in oil is required to reduce the opportunity for oxidation or other reaction.

More Information on Praseodymium Sputtering Targets

Applications• Electronics• Semiconductor • Flat panel displays |

Features• Competitive pricing• High purity • Grain refined, Engineered microstructure • Semiconductor grade |

Manufacturing Process• RefiningThree-layer electrolytic process • Melting and casting Electrical resistance furnace - Semi-continuous casting • Grain refinement Thermomechanical treatment • Cleaning and final packaging - Cleaned for use in vacuum Protection from environmental contaminants Protection during shipment |

Options• 99.9% minimum purity• Smaller sizes also available for R&D applications • Sputtering target bonding service |

Related Products of Praseodymium Sputtering Targets

|

N/A

|

Ceramic Sputtering Targets |

|

|

Evaporation Materials N/A |

Crucibles N/A |

Metal Powders N/A |

Click to download datasheet about Praseodymium Sputtering Targets (Pr)

Click to download datasheet about Praseodymium Sputtering Targets (Pr)

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).

Related Products

FREE QUOTE