List of Sputtering Targets for Thermally Reflective Automobile Glass

Date: 2021-09-13

Abstract: The heat reflection coated glass can effectively reflect the infrared light of the sun (20-25%), block the heat from entering the vehicle (heat insulation performance > 30%), reduce the air conditioning load, maintain good light transmittance (70-75%), and maintain a clear vision. Therefore, the demand of sputtering target materials for thermal reflective coated glass is becoming increasingly strong.

List of Sputtering Targets for Tool Coating

Date: 2025-06-04

Abstract: Tool coating is often used for turning tools, manipulators, molds and other mechanical and metallurgical purposes. Coating products include drill, milling cutter, gear cutter, tap, scissors, cutter, plug, die, etc. The thickness of the film is generally 2-10 μ M. the film requires high hardness, low wear, impact resistance, high adhesion, etc. its technical level is higher than that of decorative coating. The superhard protective layer of tools and dies, including tin, ZrN, TiAlN, tic, TiCN, CrN, DLC and other Sputtering Coatings.

Influence of Target Binding and Liner Pipe Quality on Large Area Coating

Date: 2021-09-13

Abstract: Target shape, purity, density, porosity, grain size and binding quality all have a great influence on film quality and sputtering rate. Today, I want to talk about the influence of target binding and liner tube quality on large area coating.

Influence of Sputtering Target Purity and Uniformity on Large Area Coating

Date: 2021-09-14

Abstract: The shape, purity, density, porosity, grain size and binding quality of the target have great influence on the coating quality and sputtering rate. High quality target material can not only ensure the good film quality, but also extend the life cycle of Low-E products. More importantly, it can reduce production costs and improve production efficiency. Today, I will discuss with you the influence of target purity and material uniformity on large area coating.

Effect of Crystal Size and Direction of Sputtering Target on Large Area Coating

Date: 2022-09-29

Abstract: Target shape, purity, density, porosity, grain size and binding quality all have a great influence on the quality and sputtering rate of large area coating. Today, I will discuss the influence of the crystal size and crystal direction of sputtering target on large area coating.

Effect of Relative Density and Gap of Sputtering Target on Large Area Coating

Date: 2021-09-14

Abstract: As a large raw material for coating, the characteristics of sputtering target, including target shape, purity, density, porosity, grain size and binding quality, have a great influence on film quality and sputtering rate. Today, I will discuss the influence of the relative density and gap of sputtering target on large area coating.

Comparison of Utilization Ratio Between Planar and Rotating Sputtering Target

Date: 2021-09-14

Abstract: The shape of sputtering target directly affects the stability and film characteristics of magnetron sputtering coating, as well as the utilization rate of the target. Therefore, the quality and production efficiency of the coating can be improved by changing the shape design of the target, so as to save costs.

Comparison of the Melt Casting and Spray Rotating Sputtering targets

Date: 2021-09-14

Abstract: The target material is an important raw material for vacuum coating. The purity and density of the target material directly affect the composition and comprehensive performance of the film system. With the rapid development of sputtering coating technology, new target preparation technology is emerging, and the target quality and performance have been improved significantly. Because of the high utilization rate, the rotating target has been widely used in the coating industry. AEM deposition can provide various kinds of rotating sputtering targets, as shown in the table below:

List of Sputtering Targets for Solar Cell Coating

Date: 2021-09-14

Abstract: Solar energy is mainly used to convert solar energy into heat and electricity. Among them, the photoelectric conversion is realized by the solar cell which directly converts the light energy into electric energy through the photoelectric effect. At present, the solar cell has developed to the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, and the third generation is thin-film solar cells (represented by CIGS).

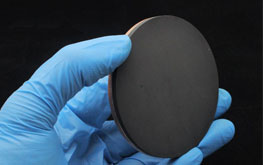

List of Sputtering Targets for Semiconductor Coating

Date: 2021-09-15

Abstract: Sputtering target material for semiconductor has a high requirement for the purity of the target material, which is generally more than 4N or 5N, so the target material for semiconductor coating is also very expensive. The sputtering targets for semiconductor coating mainly include W sputtering target, W-Ti sputtering target, Ti sputtering target, Ta sputtering target, Al sputtering target, Cu sputtering target, etc. The details are as follows:

List of Sputtering Targets for Flat Panel Display Coating

Date: 2021-09-15

Abstract: In order to ensure the uniformity of large area film, improve productivity and reduce cost, sputtering technology is more and more used to prepare flat panel display film. The sputtering targets for flat display coating mainly include Cr sputtering target, Mo sputtering target, Al sputtering target, Al alloy sputtering target, Cu sputtering target, Cu alloy sputtering target and ITO sputtering target. The details are as follows:

List of Sputtering Targets for Magnetic Recording Coating

Date: 2021-09-15

Abstract: The sputtering targets used for sputtering film recording include chromium based sputtering targets, cobalt based sputtering targets, cobalt iron sputtering targets, nickel based sputtering targets and other alloy sputtering targets. The details are as follows: