+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Evaporation Deposition Guide: Processes, Types, and Materials

Evaporation deposition is a trusted method used to apply very thin layers of material onto surfaces. It's widely used in industries like electronics, optics, and clean energy because it offers accuracy, cleanliness, and consistent results.

If you're buying materials for evaporation or involved in the coating process, it’s important to understand how this method works. A good understanding helps you choose the right materials, avoid quality issues, and work better with suppliers.

In this article, we’ll explain what evaporation deposition is, why it matters, and how it’s used in modern manufacturing—step by step and in simple terms.

What Is Evaporation Deposition?

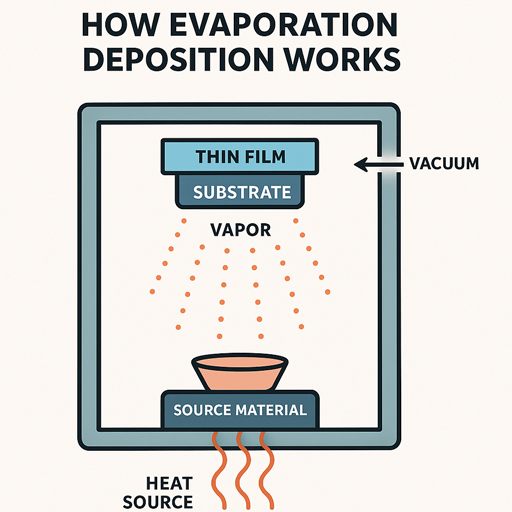

Evaporation deposition is a physical vapor deposition (PVD) process used to create thin, uniform layers of material on a substrate surface. It involves converting a solid material—typically a metal, oxide, or compound—into a vapor, and then allowing that vapor to condense into a solid film on the target surface.

The process takes place in a vacuum chamber, where the pressure is extremely low to prevent contamination and allow vapor particles to travel unimpeded from source to substrate.

Here's how it generally works:

- The evaporation material is heated until it vaporizes.

- The vapor moves upward or outward in a line-of-sight trajectory.

- The vapor condenses onto the substrate, forming a very thin, controlled film.

The final product? A high-purity, defect-free coating that can be tailored for optical, electrical, thermal, or mechanical properties, depending on the material used and the application.

How Evaporation Deposition Works

Evaporation deposition is a method where a solid material is heated until it becomes a vapor. That vapor then cools down and forms a thin layer on a surface. The process needs to be very clean and carefully controlled, because in industries like electronics, space, and optics, even small mistakes can cause big issues.

Understanding how evaporation deposition works gives material buyers the insight they need to evaluate material specifications, anticipate technical requirements, and source materials that align with exacting performance standards.

The Basic Workflow

The evaporation deposition process generally unfolds in four stages:

- Loading the Material and Substrate

- The evaporation source (e.g., metal pellets, slugs, or powder) is placed into a crucible, filament, or boat inside a vacuum chamber.

- The substrate—such as silicon wafers, optical lenses, or glass—is mounted in a position directly above or adjacent to the source.

- Creating the Vacuum

- Air and other gases are pumped out to create a high or ultra-high vacuum environment (typically 10⁻⁵ to 10⁻⁷ Torr).

- This low-pressure condition prevents unwanted reactions (like oxidation) and allows vapor to travel in straight lines without colliding with gas molecules.

- Heating the Source Material

- The material is heated via resistive heating (in thermal evaporation) or electron beam bombardment (in e-beam evaporation).

- Once the material reaches its vaporization temperature, it transforms into vapor and begins to rise or expand outward.

- Condensation on the Substrate

- The vaporized atoms travel through the vacuum and condense onto the substrate’s cooler surface, forming a thin, solid layer.

- The result is a uniform film that closely matches the characteristics of the original material, minus contaminants or structural defects.

Key Factors That Influence Deposition Quality

The quality and consistency of the deposited film are influenced by a combination of process parameters and material characteristics:

|

Factor |

Impact on Deposition |

|---|---|

|

Vacuum level |

Prevents contamination and allows straight-line travel |

|

Deposition rate |

Affects film thickness, stress, and uniformity |

|

Source material purity |

Impacts film quality and device performance |

|

Substrate temperature |

Influences adhesion and film crystallinity |

|

Distance from source |

Determines uniformity across large substrate surfaces |

When these factors are controlled correctly, the end result is a smooth, high-quality film that looks good and performs even better.

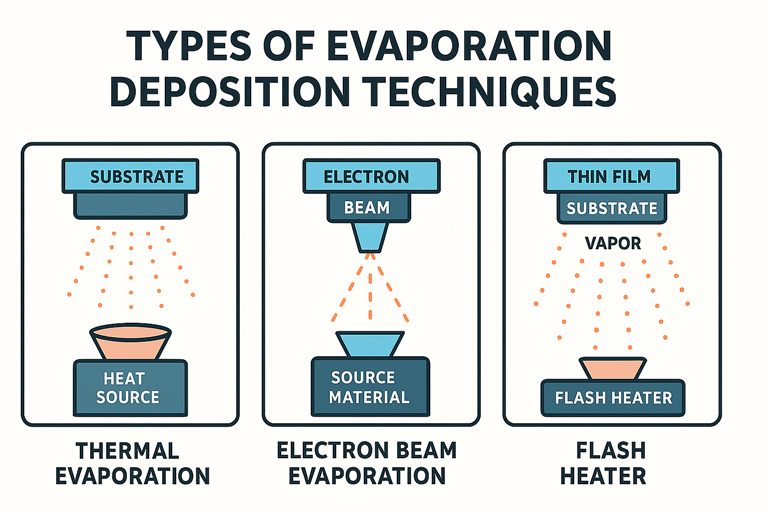

Types of Evaporation Deposition Techniques

Evaporation deposition can be performed using several different techniques, each with its own strengths, limitations, and ideal use cases. The choice of method often depends on the type of material being deposited, the desired film properties, and the capabilities of the deposition system.

For material buyers, understanding the key techniques helps ensure that the right form, purity, and packaging of material are selected for each process.

Thermal Evaporation

Thermal evaporation is one of the most established and widely used methods. In this process, the source material is placed in a resistively heated boat, coil, or crucible inside a high-vacuum chamber. As the material is heated, it melts and then vaporizes. The vapor travels through the vacuum and condenses as a thin film on the substrate surface.

- Best suited for: Materials with relatively low melting points, such as aluminum, silver, and gold.

- Common applications: Mirror coatings, electronics, packaging films.

- Advantages: Cost-effective and simple to operate.

- Considerations: Less effective for high-melting-point materials; limited control over evaporation rate for some materials.

Electron Beam (E-Beam) Evaporation

E-beam evaporation uses a focused electron beam to directly heat the source material. This method allows for precise, localized heating and is particularly useful for materials with very high melting points or those sensitive to contamination.

- Best suited for: Tungsten, titanium, molybdenum, platinum, and oxides.

- Common applications: Semiconductor layers, optical coatings, aerospace components.

- Advantages: High material utilization, excellent purity, precise control over deposition.

- Considerations: Requires more complex equipment; maintenance and calibration are critical.

Reactive Evaporation

In reactive evaporation, a reactive gas such as oxygen or nitrogen is introduced into the vacuum chamber during the deposition process. The evaporated material reacts with the gas either in the vapor phase or on the substrate surface, forming a compound film such as an oxide or nitride.

- Best suited for: Titanium dioxide (TiO₂), silicon nitride (Si₃N₄), aluminum oxide (Al₂O₃).

- Common applications: Optical filters, anti-reflective coatings, protective films.

- Advantages: Enables the formation of complex compound layers using simple starting materials.

- Considerations: Requires precise gas flow control and real-time process monitoring.

Flash Evaporation

Flash evaporation is used when materials need to be rapidly heated and evaporated. In this method, small quantities of material are introduced onto a very hot surface, causing them to instantly vaporize.

- Best suited for: Organic compounds or heat-sensitive materials.

- Common applications: Research labs, specialty coatings, low-volume applications.

- Advantages: Quick process and good for volatile materials.

- Considerations: Less suitable for large-scale manufacturing or thick films.

Co-Evaporation

Co-evaporation involves evaporating two or more materials at the same time from separate sources. This allows the vapors to mix and form a composite or alloy coating on the substrate.

- Best suited for: Thin-film solar cells, advanced alloys, and custom film structures.

- Common applications: Photovoltaics, display technologies, R&D environments.

- Advantages: Enables tailored film compositions and layered structures.

- Considerations: Requires precise control over each source's evaporation rate to maintain film uniformity.

Choosing the Right Method

Selecting the appropriate evaporation technique depends on:

- Material type and melting point

- Desired film thickness and properties

- System configuration (thermal or e-beam capable)

- Application performance requirements

As a material buyer, knowing which deposition method your end-user employs helps you:

- Choose the correct material form (e.g., pellets vs. slugs)

- Ensure compatibility with evaporation sources (e.g., boats, crucibles, hearths)

- Specify the required purity and reactivity levels

- Select suitable packaging to preserve quality from shipment to chamber loading

Sourcing Evaporation Materials: What Material Buyers Must Know

In evaporation deposition, the quality of your coating depends heavily on the quality of the source material. For material buyers, this means your role isn’t just administrative—it's strategic. Selecting the right evaporation materials can directly impact coating performance, process efficiency, yield, and even equipment lifespan.

Whether you’re managing a single purchase or setting up a long-term sourcing plan, here’s what you should consider to ensure smooth, cost-effective, and high-quality production.

Prioritize Purity: The Foundation of Reliable Coatings

Purity is not optional—it's essential.

Even small traces of contamination in the evaporation material can lead to:

- Surface defects in the thin film

- Poor adhesion or inconsistent thickness

- Reduced electrical or optical performance

- Unwanted reactions during the evaporation process

What to look for:

- Minimum 99.99% (4N) purity for general industrial applications

- 99.999% (5N) or higher for semiconductors, optics, or medical coatings

- Trace metal analysis and other impurity data from suppliers

Always request a Certificate of Analysis (CoA) with each batch to confirm the material meets your technical standards. If the supplier can't provide it, that's a red flag.

Select the Right Material Form for Your Equipment

Evaporation materials are manufactured in different physical forms to match specific equipment types and deposition setups. The most common forms include:

|

Form |

Best For |

|---|---|

|

Pellets |

E-beam evaporation; high density and low dust risk |

|

Slugs |

Larger evaporation sources; thermal boats and crucibles |

|

Granules |

Thermal evaporation; better surface coverage in boats |

|

Powder |

Specialized applications or R&D; may require sealed handling |

|

Pieces/Tablets |

General-purpose systems; often custom-sized |

Why it matters:

Using the wrong form can lead to inconsistent evaporation rates, spitting, or equipment contamination.

Tip: Confirm with your coating team or equipment manual before placing the order. Some systems require specific dimensions or densities for optimal performance.

Sourcing the right evaporation materials requires attention to detail, from purity and packaging to lead times and compatibility. By asking the right questions and working with trusted suppliers, you can help your team achieve better coatings, lower failure rates, and higher production efficiency.

Conclusion: The Right Evaporation Material Makes All the Difference

Evaporation deposition is a trusted technique in industries that demand high-quality coatings, such as electronics, optics, energy, and aerospace. But the success of any deposition process depends heavily on the quality, form, and compatibility of the materials used.

As a material buyer, your role is more than just placing an order. You are helping ensure that production runs smoothly, coatings perform reliably, and quality standards are met. When materials are well-matched to the process—clean, high-purity, and properly packaged—the results are consistent and dependable.

By understanding key factors like evaporation method, material form, purity levels, and supplier support, you can make smarter sourcing decisions that help reduce risks, save time, and improve performance.

Let Us Help You Find the Best-Fit Evaporation Materials

Whether you need high-purity metals, specialty compounds, or custom-formulated alloys, we're here to help you make the right choice.

We offer:

- A wide range of evaporation materials in various forms (pellets, slugs, powder, tablets)

- High-purity options suitable for thermal or e-beam systems

- Secure, contamination-free packaging and traceable documentation

- Fast response times and technical support tailored to your needs

Need help selecting a material? Want to request a quote or sample? Our team is ready to support your next project with reliable materials and clear answers.