+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

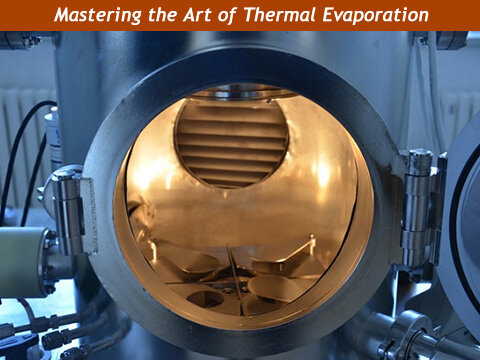

The Art of Thermal Evaporation: A Step-by-Step Guide

Are you interested in learning about thermal evaporation? If so, you're in luck! This guide will teach you all about this technique step-by-step, so you can get precise and reliable results. Thermal evaporation is a common way to add thin coatings to things like electronics, optics, and research materials. Knowing the process and its details can make a big difference in getting the best results.

We'll make it easy for you by breaking down the process into simple steps. You'll learn how to choose the right materials and equipment, and how to fix common problems. Whether you're new to thermal evaporation or an experienced researcher, you'll find helpful tips and tricks here.

Our guide has a mix of technical expertise and practical advice, so you'll feel confident using thermal evaporation. Let's start learning about this versatile coating technique now!

The Importance of Thermal Evaporation in Various Industries

Thermal evaporation is a really important process in many industries, like electronics, optics, and research. In the electronics industry, it is used to put a layer on electronic parts to make them work better and last longer. In the optics industry, it is used to make lenses and mirrors work better by making them more reflective and less shiny.

In research, it is used to make thin films for experiments and study their properties. Thermal evaporation is important because it can be used in so many different ways and fields.

Thermal evaporation has a lot of advantages over other coating methods. It lets us control how thick and even the coating is, so it always works the same way. It's also really simple and doesn't cost a lot, so more people can use it. Plus, we can use it at low pressures, to coat materials that would be hard to coat otherwise. That's why we use it so much!

Even though thermal evaporation is really useful, it's also important to understand how it works and be careful when we use it. In the next section, we'll learn more about how thermal evaporation works.

Understanding Thermal Evaporation Principles

Thermal evaporation uses heat to turn a solid material into gas. This gas forms a thin film on a substrate when it cools down.

The temperature needed for evaporation depends on the material's properties, like its melting point. Different materials need different heating methods to evaporate properly. Knowing your material's requirements is important for successful thermal evaporation.

Other factors, like the temperature of the substrate, the angle of deposition, and the chamber pressure, affect how fast the film forms and its quality. Adjusting these factors lets you control the thickness, adhesion, and structure of the film. Sometimes, you need to experiment to get the film you want.

Now that you know the basics of thermal evaporation, let's look at what you need to start.

Equipment and Materials Needed for Thermal Evaporation

To perform thermal evaporation, you will need special equipment designed for this purpose. Here are the five key components:

Evaporation Source:

This is where the material to be evaporated is placed. There are different types of evaporation sources, like evaporation boats and crucibles, depending on the material and how fast you want to evaporate it.

Vacuum Chamber:

The vacuum chamber creates a low-pressure environment, which is necessary for thermal evaporation. It should be able to reach high vacuum levels to keep the deposition process clean.

Heating System:

The heating system heats up the material so that it evaporates. The method used depends on the material and its specific requirements.

Substrate Holder:

The substrate holder holds the surface on which the thin film will be deposited. It should be designed to fit different substrate sizes and allow for precise temperature control.

Power Supply:

The power supply provides electrical power to the heating system, controlling the heating rate and maintaining a stable temperature.

Choosing the right materials is important for successful thermal evaporation. Common materials used include metals, metal oxides, semiconductors, and organic compounds. Now that we have covered the equipment and materials, let's look at the step-by-step guide to the thermal evaporation process.

Thermal evaporation uses heat to turn a solid material into gas. This gas forms a thin film on a substrate when it cools down. The temperature needed for evaporation depends on the material's properties, like its melting point. Different materials need different heating methods to evaporate properly. Knowing your material's requirements is important for successful thermal evaporation.

Other factors, like the temperature of the substrate, the angle of deposition, and the chamber pressure, affect how fast the film forms and its quality. Adjusting these factors lets you control the thickness, adhesion, and structure of the film. Sometimes, you need to experiment to get the film you want.

Now that you know the basics of thermal evaporation, let's look at what you need to start.

Step-by-Step Guide to Thermal Evaporation Process

Thermal evaporation is a way to create a thin coating on a surface. Here's how to do it:

Get Ready:

Make sure everything is ready to go. Clean the vacuum chamber and the surface you want to coat. Prepare the material you want to evaporate.

Pump and Vacuum:

Remove all the gas from the chamber. This makes sure the surface gets coated the way you want it to.

Put the Surface in the Chamber:

Put the surface in the chamber. Make sure it's clean and doesn't have any dirt or dust on it.

Evaporate the Material:

Heat up the material you want to evaporate. This will turn it into a gas that will coat the surface. Make sure the temperature is right so it evaporates at the right speed.

Control the Thickness:

Keep track of how much material is evaporating and how long it's taking. Adjust the temperature and time if you need to.

Cool the Surface and Take it Out:

Once you've got the right thickness, cool down the surface slowly. Then take it out of the chamber. Be careful not to damage the coating.

Congratulations! You've finished the thermal evaporation process. But sometimes things don't go as planned. In the next section, we'll talk about common problems and how to fix them.

Troubleshooting Common Issues in Thermal Evaporation

If you're doing thermal evaporation, you might run into some problems. Here are some common issues and how to fix them:

Poor Film Adhesion:

Sometimes the film doesn't stick well to the surface it's supposed to. To fix this, make sure the surface is clean and free from dirt. You can use special cleaning techniques to make sure it's really clean. Also, try heating the surface when you're applying the film.

Uneven Film Thickness:

Sometimes the film isn't the same thickness everywhere. This can be fixed by making sure the heat source is evenly heated and by adjusting how fast the film is applied.

Contamination:

Sometimes the vacuum chamber isn't clean and has gases or dirt in it. You can fix this by making sure the vacuum chamber is clean before you start. You should also clean it regularly.

Cracks or Pinholes:

Sometimes the film has cracks or tiny holes in it. This can be fixed by making sure the surface is smooth before you apply the film.

By knowing how to fix these issues, you can make sure your thermal evaporation works well. But always be safe when you're doing this. Let's talk about some safety tips now.

Safety Tips for Using Thermal Evaporation

Thermal evaporation is a process that heats materials to high temperatures in a vacuum. It can be dangerous if you don't take the right safety measures. Here are some tips to help you stay safe:

- Wear safety gear like safety glasses, gloves, and a lab coat to protect yourself from any potential hazards.

- Use your thermal evaporation system in a well-ventilated area or a fume hood to remove any harmful fumes or gases that may be produced during the process.

- Be careful when handling materials, as some may be toxic or hazardous. Follow the manufacturer's guidelines and safety data sheets (SDS) for proper handling, storage, and disposal of materials.

- Regularly check and maintain your thermal evaporation equipment to make sure it is safe to use. Follow the manufacturer's instructions for equipment setup, calibration, and maintenance. If you see any problems or malfunctions, get help from a qualified technician.

Know how to deal with possible accidents or equipment failures. Keep emergency contact numbers handy in case you need immediate assistance. By following these safety tips, you can reduce risks and create a safe work environment for thermal evaporation. Now that you know how to be safe, let's look at the different ways thermal evaporation is used in various industries.

Applications and Uses of Thermal Evaporation in Different Industries

Thermal evaporation is a process used in many different industries. Here are some of the ways it is used:

Electronics

Thermal evaporation is used in the electronics industry to make electronic devices better. It coats these devices to make them work better. It can also help make them last longer.

Optics

Thermal evaporation is used in the optics industry to make things like lenses and mirrors better. It makes them reflect light better and work more efficiently.

Research

Thermal evaporation is used in research to make thin films. These thin films are used to study new materials and see what they can do.

Solar Cells

Thermal evaporation is used in the production of solar cells. It helps make them more efficient by depositing thin layers onto them.

As technology advances, so does the field of thermal evaporation. Let's explore some of the recent advancements and innovations in thermal evaporation technology.

Advancements and Innovations in Thermal Evaporation Technology

Thermal evaporation is a technique used to deposit thin films of material onto a surface. It has many practical applications in fields such as electronics, optics, and materials science. Here are some recent advances in thermal evaporation technology that you might find interesting:

Pulsed Laser Deposition (PLD):

PLD is a technique that uses a laser to ablate (or vaporize) a material, which is then deposited onto a surface. It allows for precise control over the deposition process and can be used to create complex structures. It's particularly useful for depositing thin films of materials with high melting points or low vapor pressures.

Organic Vapor Phase Deposition (OVPD):

OVPD is a technique designed for depositing organic materials, such as those used in organic electronics and optoelectronic devices. It enables the deposition of high-quality organic films with controlled thickness and uniformity.

Atomic Layer Deposition (ALD):

ALD is a technique that combines thermal evaporation with chemical reactions. It enables the deposition of ultrathin films with precise control over thickness and composition. ALD is widely used in advanced semiconductor manufacturing, nanotechnology, and microelectronics.

In-situ Monitoring and Control:

Advanced thermal evaporation systems now incorporate in-situ monitoring and control capabilities. These features allow for real-time monitoring of the deposition process, which enhances the reproducibility and reliability of thermal evaporation techniques. As thermal evaporation technology continues to improve, it opens up new possibilities for various industries and research fields.

Conclusion: Mastering the Art of Thermal Evaporation

In conclusion, thermal evaporation is a technique used to coat thin films. It is used in industries like electronics, optics, and research. By understanding the principles, selecting the right equipment and materials, following a step-by-step process, and troubleshooting common issues, you can learn to do thermal evaporation.

It's important to always be safe and follow best practices to create a safe working environment. You can learn about the different ways thermal evaporation is used in different industries, and keep up with the latest advancements and innovations.

With this guide, you now have the knowledge and skills to start your thermal evaporation journey with confidence. So, go ahead, experiment, and unlock the endless possibilities of this fascinating coating technique!