+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

How to Test the Hardness of Ceramic Materials?

views, Updated: 2022-09-30

In many fields, we can see the figure of special ceramic materials. Special ceramic materials are generally characterized by limited thermal expansion coefficient, low density, low fracture toughness, high hardness, high elastic modulus. They are often used to make structural engineering materials such as bearings, cutting tools, grinding balls, valves, bearing beams, and hard coatings for various components.

The hardness test is the key to check the mechanical strength of ceramic workpieces, which are easily affected by wear. For example, the hardness of bearing parts has a great impact on its performance - because the hardness of the bearing affects its wear resistance, and the wear caused by the poor wear resistance leads to the precision of precision machinery significantly reduced.

About hardness

"Hardness" refers to a material's resistance to being pressed into by a harder object under another force. Generally, the macro hardness of minerals is determined by the Mohs hardness tester according to the grade 10 standard. In Mohs hardness, each mineral with high hardness can use it to scratch the mineral in front. However, because the Mohs hardness is very uneven, it is usually measured by Mohs hardness and microhardness tester.

Microhardness test is a kind of micro static test method. The most commonly used are Vickers and Knoop. They are both used to calculate the tested object's hardness by measuring the diagonal length of the residual indentation of the diamond angle cone indenter after pressing into the tested object under a certain test force through optical amplification. See below for details:

Vickers method:

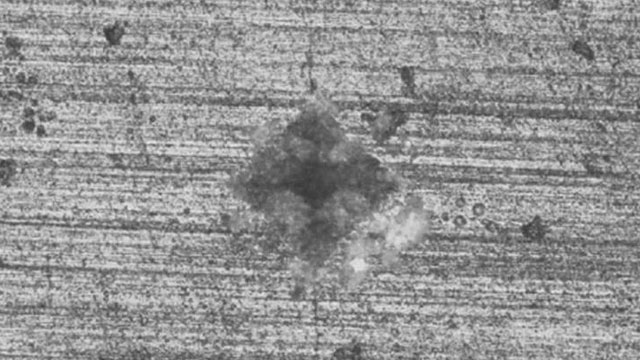

The Vickers hardness test is to press the diamond positive pyramid indenter with an included angle of 136 ° (148 ° 6'42 ") between two opposite sides into the sample's surface under a certain test force. After maintaining a certain time, remove the test force, measure the indentation's diagonal length, calculate the surface area of the indentation, and obtain the Vickers hardness value of the material.

The advantages of the Vickers method are small load, and small sample indentation can be measured, no damage to the sample. The disadvantage is that the measurement accuracy is low, and the error is large.

Vickers surface indent 10x microscope lens

Knoop hardness method:

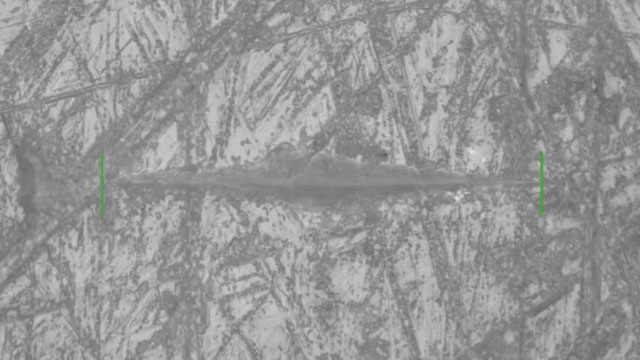

The Knoop hardness test's basic principle is to press the diamond pyramid indenter with two long edges at an angle of 172 ° 30 'and a short edge at an angle of 130 ° into the surface of the sample under a certain test force. After a certain period of time, remove the test force, measure the length of the long diagonal line of the indentation, calculate the projection area, and obtain the material's Knoop hardness value.

The load of the Knoop hardness measurement method is also small, and it can also be used to measure small sample indentation. However, because the indentation is long, it is easier to measure, so the measurement accuracy is high, and the error is small.

Knoop surface indented 40 times microscope lens

However, it should be noted that the geometric deviation of material and grain size is an important factor affecting the surface finish. Therefore, to obtain the surface quality suitable for the hardness test, it is recommended to grind or finely polish the test sample to ensure that the hardness test dent in the ceramic material is clear and visible.

LATEST NEWS