+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

The Difference between E-beam Evaporation and Thermal Evaporation

E-beam evaporation and thermal evaporation are two methods used to deposit thin films of material onto a substrate. Both methods involve vaporizing a material and condensing it onto a substrate to form a thin film. However, there are some key differences between the two methods.

1, What is E-beam evaporation

E-beam evaporation is performed using an electron beam that scans the sample's surface and then evaporates or sublimates the material just from its surface without melting it in the crucible. In general, the crucible is cooled down using a water cooling circuit. This way, the impurities located in the crucible do not diffuse in the charge and thus do not contaminate the very pure piece of material used for evaporation.

Evaporation is performed by heating a piece of material in a crucible. Both the crucible and the charge inside are heated to the desired temperature. Thus the crucible may contaminate the charge due to impurity diffusion from the crucible to the charge. However, some crucibles, such as PBN-made crucibles, are now of good purity.

2, What is Thermal evaporation

Thermal evaporation is another type of PVD process, in which a material is vaporized using heat. A crucible containing the material is heated to a high temperature, causing the material to vaporize. The vaporized material then condenses onto a substrate to form a thin film. Thermal evaporation is often used to deposit thin films of metals and alloys, and can be used to produce films with good purity and good adhesion to the substrate.

3, Main Difference Between E-beam Evaporation and Thermal Evaporation

Overall, the main difference between e-beam evaporation and thermal evaporation is the method used to vaporize the material. E-beam evaporation uses a beam of high-energy electrons, while thermal evaporation uses heat.

However, if you do not want to contaminate your charge, you should use each crucible to evaporate only one material type. Contamination-free crucibles are expensive, and they all have a range of temperature of use.

For very high-temperature evaporation, sometimes the only choice of the crucible is graphite, and thus there is a significant probability of finding carbon in the material you evaporate.

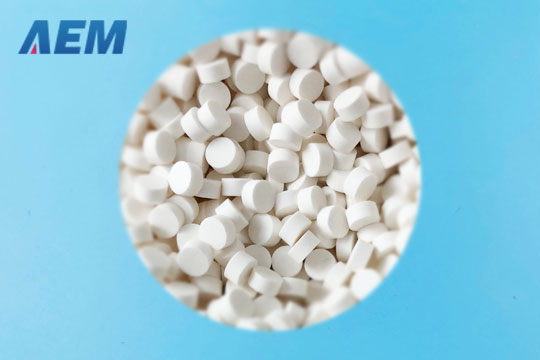

AEM Deposition is an international evaporation materials manufacturer. We have over 10 years to produce and sell evaporation materials, including Pure Metal Evaporation Materials, Alloy Evaporation materials, Oxide Evaporation Materials, and Compound Evaporation Materials. All materials are provided with various shapes, pieces, pellets, powder, rods, wires, or other sizes. If you are interested in AEM Deposition's evaporation materials, you can click the link to get more details.