Influence of Sputtering Target Purity and Uniformity on Large Area Coating

Date: 2021-01-22

Keywords: Influence,Sputtering,Target,Purity,and,Uniformity,Large,The,

Abstract: The shape, purity, density, porosity, grain size and binding quality of the target have great influence on the coating quality and sputtering rate. High quality target material can not only ensure the good film quality, but also extend the life cycle of Low-E products. More importantly, it can reduce production costs and improve production efficiency. Today, I will discuss with you the influence of target purity and material uniformity on large area coating.

Effect of Crystal Size and Direction of Sputtering Target on Large Area Coating

Date: 2021-01-22

Keywords: Effect,Crystal,Size,and,Direction,Sputtering,Target,Large,

Abstract: Target shape, purity, density, porosity, grain size and binding quality all have a great influence on the quality and sputtering rate of large area coating. Today, I will discuss the influence of the crystal size and crystal direction of sputtering target on large area coating.

Effect of Relative Density and Gap of Sputtering Target on Large Area Coating

Date: 2021-01-22

Keywords: Effect,Relative,Density,and,Gap,Sputtering,Target,Large,

Abstract: As a large raw material for coating, the characteristics of sputtering target, including target shape, purity, density, porosity, grain size and binding quality, have a great influence on film quality and sputtering rate. Today, I will discuss the influence of the relative density and gap of sputtering target on large area coating.

Comparison of Utilization Ratio Between Planar and Rotating Sputtering Target

Date: 2021-01-22

Keywords: Comparison,Utilization,Ratio,Between,Planar,and,Rotating,

Abstract: The shape of sputtering target directly affects the stability and film characteristics of magnetron sputtering coating, as well as the utilization rate of the target. Therefore, the quality and production efficiency of the coating can be improved by changing the shape design of the target, so as to save costs.

Advantages and Disadvantages of Magnetron Sputtering Technology

Date: 2021-01-22

Keywords: Advantages,and,Disadvantages,Magnetron,Sputtering,The,

Abstract: Since the appearance of magnetron sputtering, it has obtained rapid development and wide application, which has greatly impacted the position of other coating methods. So what are the advantages and disadvantages of magnetron sputtering technology?

Comparison of the Melt Casting and Spray Rotating Sputtering targets

Date: 2021-01-22

Keywords: Comparison,the,Melt,Casting,and,Spray,Rotating,Sputtering,

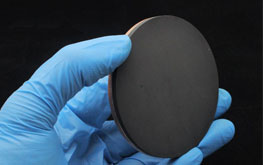

Abstract: The target material is an important raw material for vacuum coating. The purity and density of the target material directly affect the composition and comprehensive performance of the film system. With the rapid development of sputtering coating technology, new target preparation technology is emerging, and the target quality and performance have been improved significantly. Because of the high utilization rate, the rotating target has been widely used in the coating industry. AEM deposition can provide various kinds of rotating sputtering targets, as shown in the table below:

List of Sputtering Targets for Solar Cell Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Solar,Cell,Coating,Solar,energy,

Abstract: Solar energy is mainly used to convert solar energy into heat and electricity. Among them, the photoelectric conversion is realized by the solar cell which directly converts the light energy into electric energy through the photoelectric effect. At present, the solar cell has developed to the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, and the third generation is thin-film solar cells (represented by CIGS).

List of Sputtering Targets for Semiconductor Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Semiconductor,Coating,With,the,

Abstract: Sputtering target material for semiconductor has a high requirement for the purity of the target material, which is generally more than 4N or 5N, so the target material for semiconductor coating is also very expensive. The sputtering targets for semiconductor coating mainly include W sputtering target, W-Ti sputtering target, Ti sputtering target, Ta sputtering target, Al sputtering target, Cu sputtering target, etc. The details are as follows:

List of Sputtering Targets for Flat Panel Display Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Flat,Panel,Display,Coating,

Abstract: In order to ensure the uniformity of large area film, improve productivity and reduce cost, sputtering technology is more and more used to prepare flat panel display film. The sputtering targets for flat display coating mainly include Cr sputtering target, Mo sputtering target, Al sputtering target, Al alloy sputtering target, Cu sputtering target, Cu alloy sputtering target and ITO sputtering target. The details are as follows:

Development Trend of Sputtering Target Industry

Date: 2021-01-22

Keywords: Development,Trend,Sputtering,Target,Industry,Sputtering,

Abstract: Sputtering target materials have shown a rapid growth momentum in the international and domestic markets, and the era of scale application and industrialization has come. The development trend of target industry is firstly market differentiation. Products with low technology content will gradually face more fierce competition. Many small target companies have flexible mechanism and low production cost, which will make the low-end target market form the mode of price war; while the target market in the high-end industries such as magnetic recording, semiconductor, solar energy, etc. will continue to show the trend of technology leading, and the sputtering target suppliers with advanced technology at home and abroad will have an absolute advantage in the competition, and the coating manufact

List of Sputtering Targets for Magnetic Recording Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Magnetic,Recording,Coating,The,

Abstract: The sputtering targets used for sputtering film recording include chromium based sputtering targets, cobalt based sputtering targets, cobalt iron sputtering targets, nickel based sputtering targets and other alloy sputtering targets. The details are as follows:

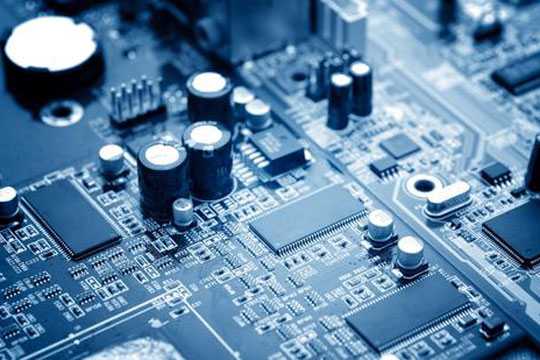

List of Sputtering Targets for Electronic Device Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Electronic,Device,Coating,List,

Abstract: Sputtering target can be used for coating electronic devices. Electronic device coating is mainly used for film resistance and film capacitance. The film resistor can provide 10-1000m Ω resistor, and the temperature coefficient of the resistor is small and the stability is good, which can effectively reduce the size of the device. Therefore, sputtering targets are often used.