Niobium Sputtering Target Video

Date: 2021-01-22

Keywords: Niobium,Sputtering,Target,Video,Niobium,Sputtering,Target,

Abstract: Niobium Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2 mm

Chromium Sputtering Target Video

Date: 2021-01-22

Keywords: Chromium,Sputtering,Target,Video,Chromium,Sputtering,Target,

Abstract: Chromium Sputtering Target.Brand: AEM Deposition.Purity: 99.95%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2 mm.

Aluminum Sputtering Target Video

Date: 2021-01-22

Keywords: Aluminum,Sputtering,Target,Video,Aluminum,Sputtering,Target,

Abstract: Aluminum Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2mm

Titanium Sputtering Target Plate Video

Date: 2021-01-22

Keywords: Titanium,Sputtering,Target,Plate,Video,Titanium,Sputtering,

Abstract: Titanium Sputtering Target.Brand: AEM Deposition.Purity: 99.99%.Size: 750 x 63.5 x 12 mm.Tolerance: ± 0.2mm

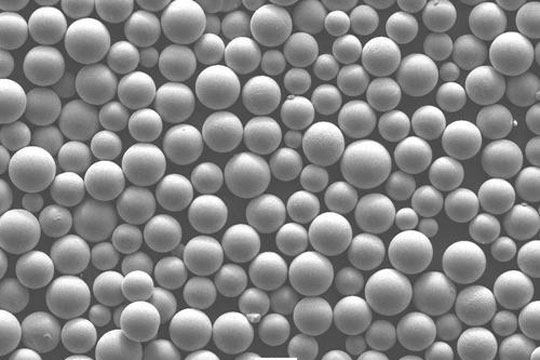

Titanium Powder Preparation by Reduction Method

Date: 2021-01-22

Keywords: Preparation,Titanium,Powder,Reduction,Method,present,the,

Abstract: At present, the preparation methods of titanium and titanium alloy powder can be divided into the following two types: 1) titanium compound reduction method; 2) titanium raw material crushing or atomization method. In addition, titanium powder needs to be modified to meet the special technological requirements.

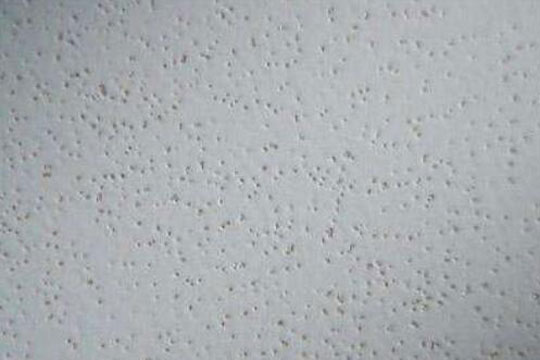

What is the Cause of Coating Shrinkage? How to Solve It?

Date: 2021-01-22

Keywords: What,the,Cause,Coating,Shrinkage,How,Solve,Various,problems,

Abstract: Various problems may occur during electrostatic powder spraying. The coating shrinkage is one of them. So, when we encounter the coating shrinkage cavity, how should we deal with it?

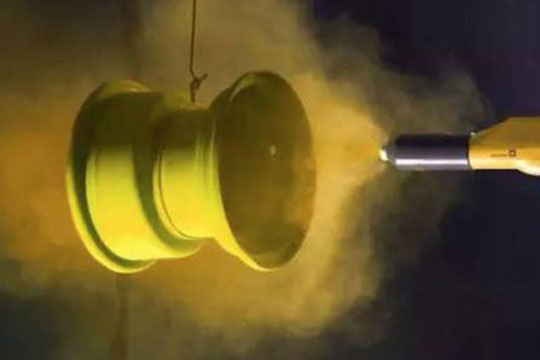

How to Deal with Impurities in the Coating During Electrostatic Powder Spraying?

Date: 2021-01-22

Keywords: How,Deal,with,Impurities,the,Coating,During,Electrostatic,

Abstract: Powder electrostatic spraying refers to the electrostatic generator releases high-voltage static electricity (negative electrode) to the space in the direction of the workpiece through the electrode needle at the gun mouth. The high-voltage static electricity ionizes the mixture of powder and compressed air ejected from the gun mouth and the air around the electrode (with negative charge). The powder is driven by electric field and compressed air pressure to the surface of the workpiece, and a uniform coating is formed on the surface of the workpiece by electrostatic attraction. AEM Deposition can provide all kinds of metal powder. The details are as follows:

List of Sputtering Targets for Shield Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Shield,Coating,Vacuum,

Abstract: Vacuum sputtering EMI has the characteristics of high conductivity and high electromagnetic shielding efficiency. It can be widely used in the EMI shielding of communication products (mobile phones), computers (laptops), portable electronic products, consumer electronics, network hardware (servers, etc.), medical instruments, home electronic products, aerospace and national defense electronic equipment. At the same time, it is suitable for metal shielding of various plastic products (PC, PC + ABS, ABS, etc.).

List of Sputtering Targets for Low Radiation Building Glass

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Low,Radiation,Building,Glass,

Abstract: There are many sputtering targets that can be used for architectural glass coating, such as Ag, Ni / Cr, Sn (SnO2 film), Ti / TiO2 (TiO2 film), Zn (ZnO film), Si / SiAl (SiN film), ZnAl, ZnSn, ZnSnSb, Cr, Nb, Nb2O5 and other sputtering targets, as follows:

List of Sputtering Targets for Thermally Reflective Automobile Glass

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Thermally,Reflective,Coated,

Abstract: The heat reflection coated glass can effectively reflect the infrared light of the sun (20-25%), block the heat from entering the vehicle (heat insulation performance > 30%), reduce the air conditioning load, maintain good light transmittance (70-75%), and maintain a clear vision. Therefore, the demand of sputtering target materials for thermal reflective coated glass is becoming increasingly strong.

List of Sputtering Targets for Tool Coating

Date: 2021-01-22

Keywords: List,Sputtering,Targets,for,Tool,Coating,Tool,coating,often,

Abstract: Tool coating is often used for turning tools, manipulators, molds and other mechanical and metallurgical purposes. Coating products include drill, milling cutter, gear cutter, tap, scissors, cutter, plug, die, etc. The thickness of the film is generally 2-10 μ M. the film requires high hardness, low wear, impact resistance, high adhesion, etc. its technical level is higher than that of decorative coating. The superhard protective layer of tools and dies, including tin, ZrN, TiAlN, tic, TiCN, CrN, DLC and other Sputtering Coatings.

Influence of Target Binding and Liner Pipe Quality on Large Area Coating

Date: 2021-01-22

Keywords: Influence,Target,Binding,and,Liner,Pipe,Quality,Large,Area,

Abstract: Target shape, purity, density, porosity, grain size and binding quality all have a great influence on film quality and sputtering rate. Today, I want to talk about the influence of target binding and liner tube quality on large area coating.