+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Influence of Target Binding and Liner Pipe Quality on Large Area Coating

views, Updated: 2021-09-13

Target shape, purity, density, porosity, grain size, and binding quality greatly influence film quality and sputtering rate. Here we discuss the influence of target binding and liner tube quality on large-area coating.

Effect of target binding on large area coating

To avoid the fracture of brittle materials such as metal, alloy, or oxide with low toughness, the target is usually bound to the copper backplate when preparing the planar target. In contrast, the rotating target is tied to the stainless steel liner, and the commonly used binding material is metal indium . In addition to protecting the target from accidental rupture during transportation, it can also improve the problem of insufficient mechanical strength of the target and solve the problem of limited preparation and use of large-scale target by splicing the target to the backplate (liner tube). It can ensure good cooling and electrical contact of the target and prevent the target from uneven sputtering and cracking during sputtering.

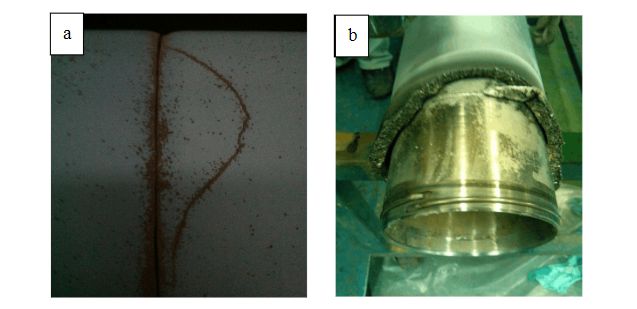

Because the target will generate much heat in the sputtering process, while the ceramic target, such as azo sputtering target has poor heat dissipation performance. If a large area of binding is not good (the invalid binding area of binding target is greater than 10% of the contact area of target and liner/backplane). In that case, it is very easy to generate local heat accumulation in the sputtering process. The low melting point binding material indium (melting point is 156 ℃) melts, resulting in target opening crack or even fall off. At the same time, due to ZnO's presence, the surface of the azo target is often nodulated in the process. The striking arc discharge is more likely to occur at the crack, which aggravates the slagging (see Fig.1a), seriously affect the use power and cycle of the target. It reduces the coated products' production efficiency increases the production cost. Moreover, the uneven heat conduction and conductivity will cause uneven sputtering (uneven film formation) of the target material, and the phenomenon of surface and discharge will also cause uneven film formation, and the difference of film color will appear. The difference between the three silver products, which are sensitive to the change of the dielectric layer, is more prominent, which will increase the scrap rate of the coating. Therefore, the binding quality of the target has a significant impact on its use.

The effect of target bonding material on large area coating

There are some metal or alloy rotating targets with good thermal conductivity, such as ZnAl sputtering target, ZnSn sputtering target, SiAl sputtering target. Due to the difference between the target material and the stainless steel pipe thermal expansion coefficient (the regular coefficient that the geometric size changes with the change of temperature under the effect of thermal expansion and contraction), it is also necessary to use some connecting material for bonding. If the combination is not good, there will also be uneven heating of the target, blocked heat conduction, cracking, and falling off (as shown in Fig. 1b), which will affect the coated products' quality and production.

Figure1: target abnormality caused by binding quality

The influence of the quality of target liner on large area coating

In addition to binding quality, the quality of the stainless steel liner pipe affects coating production.

When the chamfer inside the end of the stainless steel pipe is too large or too small (generally 25 °), there are large scratches, gouges, deformation, or impurities at the end or installation thread. It is easy to cause air leakage due to loose sealing, leading to low vacuum, abnormal sputtering film composition, poor uniformity, and other factors affecting coated products' quality. Simultaneously, the straightness and inner diameter of the stainless steel pipe will also affect its use. If the inner diameter of the stainless steel tube target cylinder is small or there is an overall deviation of the inner diameter (only the size of the end meets the requirements of the inner diameter). After installing the magnetic steel, serious friction between the magnetic steel and the target is likely to occur during the production process. When the target is rotated, it will jump seriously, which will damage the end and affect the film-forming quality. Especially for the magnetic steel with slight deformation after a long service time, the target liner requirements are relatively higher.

AEM Deposition, as a professional sputtering target supplier, supplies all kinds of pure metal sputtering target, alloy sputtering target, and ceramic compound sputtering target. The details are as follows:

Interested people can directly click the relevant links to enter the product page. You can also email us at [email protected].

LATEST NEWS