+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Titanium Nitride Coating: Applications, Benefits & Target Solutions

What Is Titanium Nitride Coating?

Titanium nitride (TiN) coating is a thin, gold-colored layer often applied to metal surfaces to improve performance. It's known for being extremely hard, wear-resistant, and chemically stable, making it ideal for demanding industrial applications.

This coating is typically created through physical vapor deposition (PVD) methods like sputtering. In the process, titanium is combined with nitrogen gas in a vacuum chamber to form a very thin TiN layer—usually just 1–5 microns thick. Despite being so thin, it makes a big difference in durability.

What makes TiN special is its ability to resist wear, corrosion, and heat, reduce friction, and still conduct electricity—unlike most ceramic coatings. Because of these properties, titanium nitride is used across many industries: protecting cutting tools, enhancing semiconductor components, and even coating medical devices.

In thin-film coating systems, the quality of the titanium sputtering target directly affects the coating's performance. That's why high-purity, custom-manufactured targets—like the ones AEM Deposition provides—play a critical role in the success of your PVD process.

Key Benefits of Titanium Nitride Coatings

Titanium nitride (TiN) coatings are widely used because they improve how products perform in tough environments. Whether it's cutting tools, microchips, or medical devices, TiN helps them last longer, stay stable, and work more efficiently.

Stronger Surface, Longer Life

TiN creates a hard, protective surface that resists wear and scratching. This helps tools and components keep their shape and function longer, even with frequent use.

Protects Against Corrosion and Heat

The coating stands up well to chemicals, moisture, and high temperatures. This makes it a reliable choice in industries where parts are exposed to harsh working conditions.

Reduces Friction

TiN coatings make surfaces smoother, so moving parts slide better and generate less heat. This improves efficiency and reduces energy loss during operation.

Conducts Electricity

Unlike most ceramic coatings, titanium nitride is electrically conductive. That’s a key reason it’s used in semiconductors and electronics, where both protection and electrical performance are needed.

Industries Using Titanium Nitride Coatings

Titanium nitride coatings are trusted in industries where durability, precision, and performance are critical. From heavy-duty manufacturing to micro-scale electronics, TiN offers protection and stability where it matters most.

Semiconductor & Microelectronics

In chip manufacturing, TiN is used as a barrier layer and conductive coating. It helps prevent unwanted diffusion between materials and maintains electrical performance in transistors, capacitors, and contact layers. Its conductivity and thermal stability make it essential in modern integrated circuit design.

Cutting Tools & Industrial Components

Drill bits, end mills, dies, and molds often use TiN coatings to extend tool life. The hard surface protects against edge wear, reduces downtime, and improves cutting efficiency—especially in high-speed or dry machining operations.

Medical Devices

Surgical tools and implants benefit from TiN’s biocompatibility and corrosion resistance. It creates a smooth, inert surface that reduces metal ion release and supports long-term use inside the human body.

Aerospace & Automotive

Components exposed to high temperatures and friction—such as engine parts, valves, or fasteners—use TiN coatings to maintain performance under stress. It helps reduce oxidation, improve heat resistance, and extend service intervals.

Consumer & Luxury Products

Thanks to its distinctive gold color and wear resistance, TiN is also used in watches, eyewear, and decorative hardware where both function and appearance are important.

How Titanium Nitride Coatings Are Made

Titanium nitride (TiN) coatings are applied using PVD (Physical Vapor Deposition), a vacuum-based method that allows for thin, uniform, and high-performance coatings on a wide range of materials.

Sputtering Process: Titanium + Nitrogen

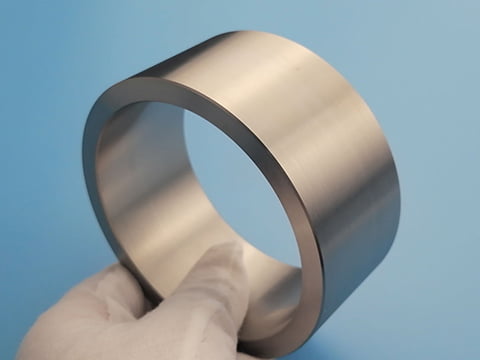

The most common way to produce TiN coatings is through reactive sputtering. In this process, a high-purity titanium sputtering target is placed inside a vacuum chamber. Argon gas is introduced to create plasma, which knocks titanium atoms off the target surface.

At the same time, nitrogen gas is added to the chamber. As the titanium atoms travel toward the substrate (such as a tool or wafer), they react with nitrogen and form a thin layer of titanium nitride.

This coating is tightly bonded to the surface and can be precisely controlled in thickness, usually just a few microns, making it ideal for both protective and functional applications.

Why Sputtering Target Quality Matters

The quality of the titanium sputtering target directly affects the coating's performance. If the target contains impurities or has uneven density, it can cause coating defects, poor adhesion, or inconsistent results.

That's why AEM Deposition manufactures titanium targets with strict process control—starting from vacuum melting, precision machining, to final surface grinding. The result is a dense, pure, and stable sputtering target that supports reliable TiN coatings across industrial production lines.

Why Target Quality Matters for TiN Coating Performance

In TiN coating production, the quality of the titanium sputtering target directly affects the final film’s performance. Even with advanced PVD equipment, a poor-quality target can lead to coating defects, downtime, or inconsistent results.

High Purity Means Cleaner Films

If the titanium target contains impurities, those elements can show up in the coating—causing problems like poor adhesion, electrical failure, or unwanted color shifts. For critical applications like semiconductors or precision tools, high-purity titanium (3N–4N5) helps ensure the film is clean, stable, and reliable.

Good Density = Smooth, Even Coating

A dense and uniform target allows the sputtering process to run smoothly. It helps maintain a consistent deposition rate and film thickness. If the target has pores, cracks, or uneven grain, it can create arc spots or particles that lower film quality.

Strong Structure Supports Production

During high-power sputtering, the target must stay mechanically stable under heat and pressure. Well-made targets with proper machining and surface finish reduce the risk of failure and improve system uptime.

Conclusion: TiN Coatings Perform Best with the Right Titanium Target

Titanium nitride coatings improve durability, reduce wear, and protect products in many industries. But the quality of the coating depends heavily on the titanium target used during sputtering.

A high-purity, well-made titanium target helps create smooth, stable coatings with fewer defects. It also supports consistent results across different batches—important for tools, electronics, and precision parts.

AEM Deposition supplies titanium sputtering targets specifically designed for TiN coatings. We offer custom sizes, small order quantities, and fast delivery.

Let’s make your TiN coating process more stable and efficient.

→ [Contact AEM Deposition] to get a quote or speak with our team.