+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

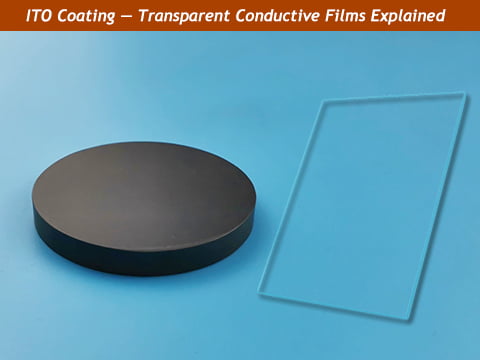

ITO Coating: Transparent Conductive Films Explained

1. Understanding ITO Coating: What & Why

ITO, short for Indium Tin Oxide, is a special material made by mixing indium oxide (In₂O₃) and tin oxide (SnO₂). What makes ITO unique is that it can conduct electricity like a metal while also being transparent like glass. Because of this rare combination, it’s widely used in products that need clear but conductive surfaces — such as touchscreens, displays, solar panels, and smart windows.When ITO is applied as a very thin layer — usually less than one micrometer thick — it forms what we call an ITO coating. This coating lets light pass through while allowing electrical signals to move across the surface. For example, when you touch your phone screen, it’s the ITO layer that senses your touch and sends that signal to the device.

Most ITO coatings are made using a process called vacuum sputtering. In this method, ions hit an ITO sputtering target, knocking off tiny particles that settle evenly on glass or plastic to form a smooth, uniform coating. The quality of the sputtering target directly affects how well the final coating performs.

At AEM Deposition, we manufacture high-purity ITO sputtering targets designed for stable coating performance and excellent film quality. Our targets help customers produce coatings with high transparency, low resistance, and strong durability — all key for advanced electronic and optical applications.

In short, ITO coatings make modern transparent electronics possible. They're the invisible layers that connect light, energy, and technology — helping displays shine brighter, solar panels work better, and smart glass respond faster.

2. What Makes a Great ITO Film: Composition, Microstructure & Performance Metrics

A high-quality ITO coating starts with the right material composition and controlled microstructure. These two factors decide how transparent and conductive the final film will be.Balanced Composition

ITO is usually made of about 90% indium oxide (In₂O₃) and 10% tin oxide (SnO₂) by weight.The indium oxide provides the basic transparent framework, while the small amount of tin oxide adds extra free electrons, which make the film conductive.If there’s too little tin, the film won’t conduct electricity well. If there’s too much, the transparency drops. That’s why keeping this balance is critical.Microstructure and Film Quality

The way ITO crystals form during deposition affects how electrons and light move through the film.· Smaller, uniform grains give smoother films and better transparency.

· Larger or uneven grains can scatter light, making the coating slightly hazy.

· Films that are densely packed also resist cracking and last longer under heat or humidity.

At AEM Deposition, our ITO targets are sintered to a high density and finely controlled grain structure, ensuring the film deposits evenly and consistently across the substrate.

Key Performance Metrics

Engineers usually evaluate ITO coatings by three main parameters:· Visible light transmittance: normally above 85%, which keeps screens and windows clear.

· Resistivity or sheet resistance: a measure of how easily current flows. High-end ITO films can reach 10⁻⁴ – 10⁻³ Ω·cm.

· Surface uniformity: essential for even color, brightness, and electrical response in display and optical applications.

Balancing these properties is always a trade-off — increasing conductivity can slightly reduce transparency, and vice versa. With the right sputtering target and optimized process, you can achieve both.

3. How ITO Coating Is Manufactured — What Your Supplier (or You) Must Control

Producing a high-quality ITO coating involves two key parts:1. Making the ITO sputtering target, and

2. Depositing the coating onto the substrate by sputtering.Each stage requires precision, because small variations can greatly affect how the final film performs.

Step 1: ITO Target Preparation

ITO is a ceramic oxide material — it cannot be melted and cast like metals.Instead, it’s made using a powder metallurgy process. Fine powders of indium oxide and tin oxide are mixed in the right ratio, pressed into shape, and then sintered at high temperature to form a dense, solid target.This sintering process determines the density, purity, and microstructure of the target, which directly influence coating quality.

At AEM Deposition, our ITO targets are produced with:

· High purity (≥ 99.99%)

· Uniform grain size and chemical consistency

· Strong mechanical stability to withstand long sputtering runs

After sintering, the targets are CNC-machined for dimensional precision and, if needed, bonded to copper or aluminum backing plates. The backing plate helps conduct heat away during sputtering and keeps the target stable.

Step 2: Sputtering Deposition Process

Once the ITO target is ready, it’s installed in a vacuum sputtering chamber.Inside, argon gas (and a small amount of oxygen) is introduced. When the process starts, energetic ions strike the ITO target surface, knocking off atoms that settle evenly on the substrate — forming the thin ITO film.To achieve a high-performance coating, several process parameters must be controlled carefully:

· Chamber vacuum level — prevents oxidation and impurities.

· Oxygen partial pressure — affects film stoichiometry and resistivity.

· Substrate temperature — influences crystal structure and transparency.

· Deposition rate and uniformity — ensure consistent thickness and appearance.

Even small changes in these conditions can lead to large differences in film conductivity or optical clarity.

Step 3: Post-Deposition Treatment

After coating, many manufacturers perform a short annealing step (typically at 300–500 °C).This heating improves the crystal structure and reduces defects, leading to:· Lower electrical resistance

· Higher transparency

· Better adhesion to the substrate

At AEM Deposition, we don’t just supply the targets — we help customers understand how target quality and sputtering conditions work together. Our high-density, uniform ITO targets help coating lines achieve:

· Excellent film uniformity

· Stable resistivity

· Longer target life and less downtime

4. Applications of ITO Coating

ITO coatings are used anywhere a surface needs to be transparent and electrically conductive. From everyday consumer electronics to advanced energy and optical systems, ITO plays a quiet but essential role in modern technology.1. Displays and Touch Panels

One of the largest uses of ITO is in LCD, OLED, and touch-screen displays.In these devices, ITO acts as the transparent electrode layer that carries the electrical signals needed to create images or detect touch.Because it’s both clear and conductive, ITO allows screens to respond instantly while keeping visuals bright and vivid.AEM Deposition’s high-purity ITO targets help manufacturers produce smooth, defect-free coatings — crucial for achieving uniform color and high image resolution.2. Photovoltaic and Solar Cells

In solar panels, ITO is used as a transparent front electrode that allows sunlight to pass through while collecting electrical current from the cell.Its excellent optical transmission and low sheet resistance make it ideal for thin-film photovoltaic technologies like CIGS, CdTe, and perovskite solar cells.Our ITO targets provide consistent conductivity and thickness control, ensuring better light absorption and higher energy conversion efficiency.3. Smart Glass and Low-E Windows

ITO coatings are widely applied in energy-saving architectural glass and automotive windows.By adjusting how much infrared (IR) light passes through, these coatings can reduce heat loss in winter and block excess heat in summer — improving energy efficiency.In some designs, a small voltage applied to the ITO layer can change the glass’s transparency, creating electrochromic “smart windows” that respond to light or user control.4. Sensors and Optical Devices

ITO’s transparent conductivity also makes it valuable in various sensors, light detectors, and optical instruments.It allows precise signal measurement without blocking light, which is essential for optical communication, biosensors, and IR filters.Its smooth surface and stable properties make it suitable for thin-film transistors (TFTs) and other high-precision optoelectronic components.5. Emerging Applications

With the growth of flexible and wearable electronics, researchers are now developing flexible ITO coatings that can bend without breaking.ITO is also used in transparent antennas, LEDs, and even spacecraft coatings, where both optical clarity and conductivity are critical under extreme conditions.From smartphone screens to solar panels and smart buildings, ITO coatings enable devices to look clear, perform efficiently, and connect intelligently.At AEM Deposition, we support these industries with ITO sputtering targets that deliver the uniformity, purity, and reliability modern thin-film manufacturing requires.

5. ITO vs Other Transparent Conductive Oxides (TCOs)

Although ITO (Indium Tin Oxide) has long been the industry standard for transparent conductive films, it’s not the only option.Several alternative materials — such as AZO, FTO, and IGZO — have gained attention in recent years.Each one offers a different balance of cost, stability, and performance. Understanding these differences helps engineers choose the right material for their project.1. ITO — The Benchmark Material

ITO remains the most widely used transparent conductor thanks to its excellent combination of low resistivity and high transparency.It forms smooth, uniform films, making it ideal for high-resolution displays, touchscreens, and optical devices.However, it also has two key limitations:· Indium is expensive and relatively scarce, which can affect long-term supply costs.

· ITO coatings are brittle, which makes them less suitable for flexible or stretchable electronics.

Despite these challenges, ITO is still preferred when performance, reliability, and clarity are top priorities.

2. AZO (Aluminum-Doped Zinc Oxide)

AZO is a promising indium-free alternative made by doping zinc oxide (ZnO) with a small amount of aluminum.Its main advantages are:

· Lower material cost and easier raw-material availability

· Good transparency and chemical stability

· Environmental friendliness

However, AZO’s conductivity and durability are usually a bit lower than ITO, especially in humid or high-temperature conditions.

Still, AZO sputtering targets are a good option for large coating areas, solar panels, and research projects, where keeping costs low is more important than reaching the highest electrical performance.

3. FTO (Fluorine-Doped Tin Oxide)

FTO coatings are another indium-free option, often used on glass for low-emissivity (Low-E) or heating applications.They’re highly durable, resist oxidation, and can withstand high temperatures, making them excellent for architectural glass and automotive windows.However, FTO films usually have higher resistivity than ITO, so they’re less suitable for high-speed electronic devices or thin-film transistors.4. IGZO (Indium-Gallium-Zinc Oxide)

IGZO, short for indium gallium zinc oxide, is an advanced transparent semiconductor material made from a mix of indium, gallium, and zinc oxides.

It’s well known for its:

-

Excellent electron mobility, which allows faster signal response

-

Smooth and uniform films, ideal for precision coatings

-

Very low leakage current, improving energy efficiency

Because of these advantages, IGZO coatings are now widely used in next-generation display backplanes, especially in high-resolution OLED and LCD screens.

They make displays clearer and more power-efficient compared to traditional materials.

However, IGZO sputtering targets are more complex and expensive to produce than standard ITO targets, so they are mainly chosen for high-end applications where performance matters more than cost.

5. Choosing the Right TCO Material

Selecting between ITO, AZO, FTO, or IGZO depends on several factors:| Application | Best Material | Key Consideration |

| Touch screens & displays | ITO or IGZO | Highest clarity & conductivity |

| Solar panels | ITO or AZO | Cost vs efficiency |

| Smart windows & Low-E glass | ITO or FTO | Durability & IR control |

| Flexible electronics | AZO or hybrid ITO films | Bendability & lower cost |

At AEM Deposition, we supply a full range of TCO sputtering targets, including ITO, AZO, ZnO, and IGZO.Our experts help customers evaluate each material’s trade-offs and select the most suitable target for their thin-film system — balancing performance, cost, and long-term reliability.

6. Conclusion & Call to Action

ITO coating plays a key role in modern life.It helps make phone screens respond to touch, solar panels capture sunlight more efficiently, and smart windows adjust to heat and light.Few materials can do what ITO does — it stays clear like glass but also conducts electricity like a metal.As technology keeps moving forward, ITO coatings are becoming even more advanced.New research is making them easier to apply on flexible materials, improving their strength, and finding better ways to recycle valuable indium.Even with other materials like AZO or FTO being explored, ITO remains the most trusted choice for clear, conductive, and durable thin films.

At AEM Deposition, we help make these coatings possible by supplying high-purity ITO sputtering targets that deliver the consistent quality manufacturers need for modern displays, solar panels, and optical devices.