Bonding Ceramic Sputtering Targets to Metal Holders

views, Updated: 2021-09-23

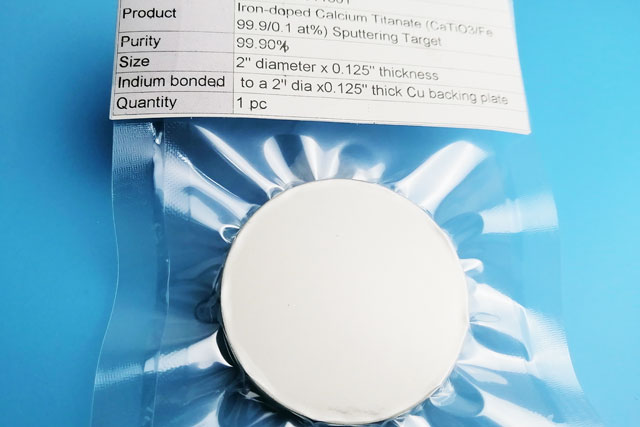

Ceramic sputter targets often need to be bonded to a metallic carrier. The better this bond provides mechanical, electrical, and thermal contact, the better and longer the target works. Next, we describe indium soldering for all of you.

The sputter targets are ceramic discs with a few millimeters in thickness. They have to be attached mechanically and coupled electrically and thermally with a metallic target holder. Insulating targets for RF sputtering can be coupled capacitively, and conducting targets for DC sputtering have to be coupled conductively.

This connection between the target holder and target disc is critical for the target to operate. It has to be vacuum-safe, stable at somewhat elevated temperature, and resistant to oxidation by the oxygen plasma. This excludes many types of glue and resins. The connection also has to be mechanically strong and resistant to fatigue: The target disc is heated on one side by the plasma and thermal radiation from the hot substrate heater with a power of at least 80W. On the other side, it is attached to the water-cooled target holder. This causes the target to expand and shrink relative to the target holder each time the target is switched on and off. If the connection between target and holder is too strong and stiff, the target may crack. If the target does not adhere to the holder strongly enough, it may be delaminated progressively. This process reduces the electrical and thermal contact and accelerates the delamination because the temperature difference between the target disc and target holder increases.

RF targets can be glued with Torr Seal, a high-vacuum glue. It seems to contain a ceramic filler that passivates the surface against oxidation by the oxygen plasma. The adhesion of this glue to metals and ceramics is excellent. Only some cracking is observed after longer target operation times.

Alternatively, targets can be soldered directly with indium using an ultrasonic soldering iron. The ultrasound breaks the thin passivating oxide skin of the reactive indium melt and brings the indium metal in direct contact with the surface to be soldered. The indium metal then reacts with the exposed oxide or metal and bonds very firmly with virtually all oxides and the metallic target holders. Pure indium and particularly indium oxide has a low vapor pressure and are therefore unproblematic in a vacuum system. Furthermore, Indium is very soft, almost like wax, and creeps rapidly even at room temperature. Mechanical stress between the target holder and the ceramic disc is thus relaxed. This makes indium soldering, in our opinion, the ideal target bonding method. So far, no target that is bonded with indium has failed during my work.

Care should be taken not to subject the target to thermal shock. A thin ceramic target disc alone survives relatively fast cooling and heating, the metallic holder as well. Both bonded together can crack, in particular, if the ceramic side is heated or cooled. Consequently, the combination of disc and holder should always be heated or cooled through the holder side, not the target side.

The connection between the target and holder can be released by heating above the melting point and then removing the holder's target disc.

LATEST NEWS

2025-05-29

2025-05-22

2025-05-09

2025-04-09

2025-04-09

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]