+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

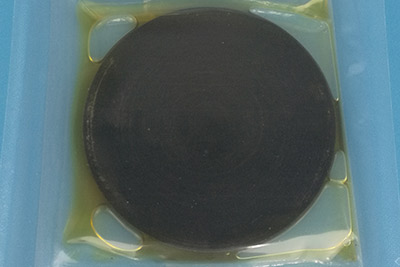

How to Clean Deposition Materials Shipped in Oil?

views, Updated: 2021-09-30

Some deposition materials may react with air and water vapor during storage and shipment, so we protect these deposition materials by immersion in a low viscosity (hydrocarbon) mineral oil. But before the material can be installed in a vacuum system, this oil must be removed entirely by using solvents that do not act as additional contamination sources for the vacuum system or the subsequent thin-film processes. About solvent choice, some highly reactive materials may react with certain solvents, so we should always select solvents that are strictly hydrocarbon in nature (i.e., the solvent molecule contains nothing but carbon and hydrogen).

We also Should Pay Attention to:

1. Do not use solvents such as alcohols, ketones, esters, ethers, furans, or others containing oxygen.

2. Do not use pyridine-like solvents containing nitrogen.

3. Do not use sulfur-containing solvents such as carbon disulfide.

4. Do not use any of the numerous chlorine-containing solvents of which trichloroethylene is an example.

5. The initial cleaning steps can use technical grade solvents to minimize the expense.

6. Technical grade hexane, heptane, iso-octane are preferred.

7. High purity grades of hexane, heptane, or iso-octane must be shipped, stored, and used from glass containers.

How to Handling Organic Solvents?

Most (perhaps all) organic solvents are health hazards, so when we are handing organic solvents, we should note:

1. Do not breathe in solvent vapors.

2. Do not accidentally swallow the solvent liquid.

3. Do not allow skin contact with the solvent.

4. Do not allow splashing solvent to touch the eyes.

5. Do not allow exposed flames or heaters near the vapor.

When we are handing solvent, we should do that in an extractive fume hood and do that only while wearing suitably protective eye shields, aprons, and absorbent respirator masks. We should do that only while wearing gloves that have been tested to demonstrate that the solvents in use neither dissolve the gloves nor permeate through them.

Points for Attention:

1. All cleaning steps must be completed as quickly as possible in a fume hood or very well ventilated area to minimize the material's exposure time to air and the operators' exposure to solvent fumes. If possible, we should clean the material in a leak-tight glove box under a slight positive pressure of argon to delay interaction between air and the material.

2. For all the time the material is in the chamber, we should ensure that: The chamber is always vented with argon, when the chamber is open, argon continues flowing at high volumetric speed, when the chamber is closed, keep it at high vacuum.

3. Tools that should be prepared in advance:

Suitably sized glass receptacles after chemically and physically clean,

Technical purity hydrocarbon solvents,

Extremely high purity hydrocarbon solvents,

Lint-free tissues,

Chemically and physically clean tongs or tweezers to handle the materials.

Operation Steps of Cleaning Deposition Materials Shipped in Oil

1. We should arrange a number, not less than three, beakers/Petrie dishes, and put sufficient technical solvent in them to completely immerse the material.

2. We should arrange a number, again not less than three, beakers/Petrie dishes and put sufficient high purity solvent in them to completely immerse the material.

3. Remove the material from its packaging and quickly wipe off the excess oil with a lint-free tissue.

4. Then, we should immerse the material in the technical solvent bath #1 immediately. Agitate material or solvent to encourage dissolution. (Note: While the material is immersed in the solvent, it is as protected from the reaction as in the original packaging. It is the time spent exposed to air that is important). Remove the material from the technical solvent bath #1 and quickly wipe off the excess solvent. Do not attempt to dry completely since this increases air exposure and does little to reduce contamination. Immediately immerse the material in technical solvent bath #2. Agitate, remove, dab dry with fresh tissue. Immediately immerse the material in technical solvent bath #3. Agitate, remove, dab dry with fresh tissue.

5. Immediately immerse the material in high purity solvent bath #1. Agitate, remove, dab dry with fresh tissue. Immediately immerse the material in purity solvent bath#2. Agitate, remove, dab dry with fresh tissue. Immediately immerse the material in purity solvent bath#3. Agitate, remove, and dab dry as completely as possible with fresh tissue.

6. Immediately transfer the material to the vacuum chamber that should be pre-flushed (and continue to be flushed) with argon to reduce air components' concentration.

7. When the material is mounted in its source, stop Ar flow, close the chamber flanges, and pump. If the material is a reactive sputter target such as Ca, Ba, Sr that quickly oxidizes, a short pre-spotter period is recommended before sputtering to produce thin-films.

LATEST NEWS