Comparison of Six Methods for Making Silicon Nitride Powder

Date: 2021-09-20

Abstract: The basic principle of the preparation of silicon nitride powder is to produce silicon nitride powder with high purity and specific crystal phase (α phase or β phase) by chemical reaction between nitrogen compounds and silicon compounds under suitable temperature and atmosphere.

Surface Treatment Process of Physical Vapor Deposition (Attached Figure)

Date: 2021-09-20

Abstract: The main methods of PVD are vacuum evaporation, sputtering, arc plasma, ion and MBE. At present, physical vapor deposition technology can deposit metal films, alloy films, compounds, ceramics, semiconductors, polymer films, etc. So, what is the process of physical vapor deposition? Look directly at the following figure:

Application of Chemical Vapor Deposition in Semiconductor Films

Date: 2021-09-20

Abstract: Chemical vapor deposition (CVD) is a well-known technology in the field of nano manufacturing. Through the use of gas-to-gas reactions, CVD can deposit evaporated reactants on the surface to form thin films. Therefore, CVD can be applied to semiconductor films.

Principle of Chemical Vapor Deposition (CVD)

Date: 2025-04-09

Abstract: Chemical vapor deposition (CVD) is a well-known technology in the field of nano manufacturing. What is the principle of CVD? Check our blog to learn more.

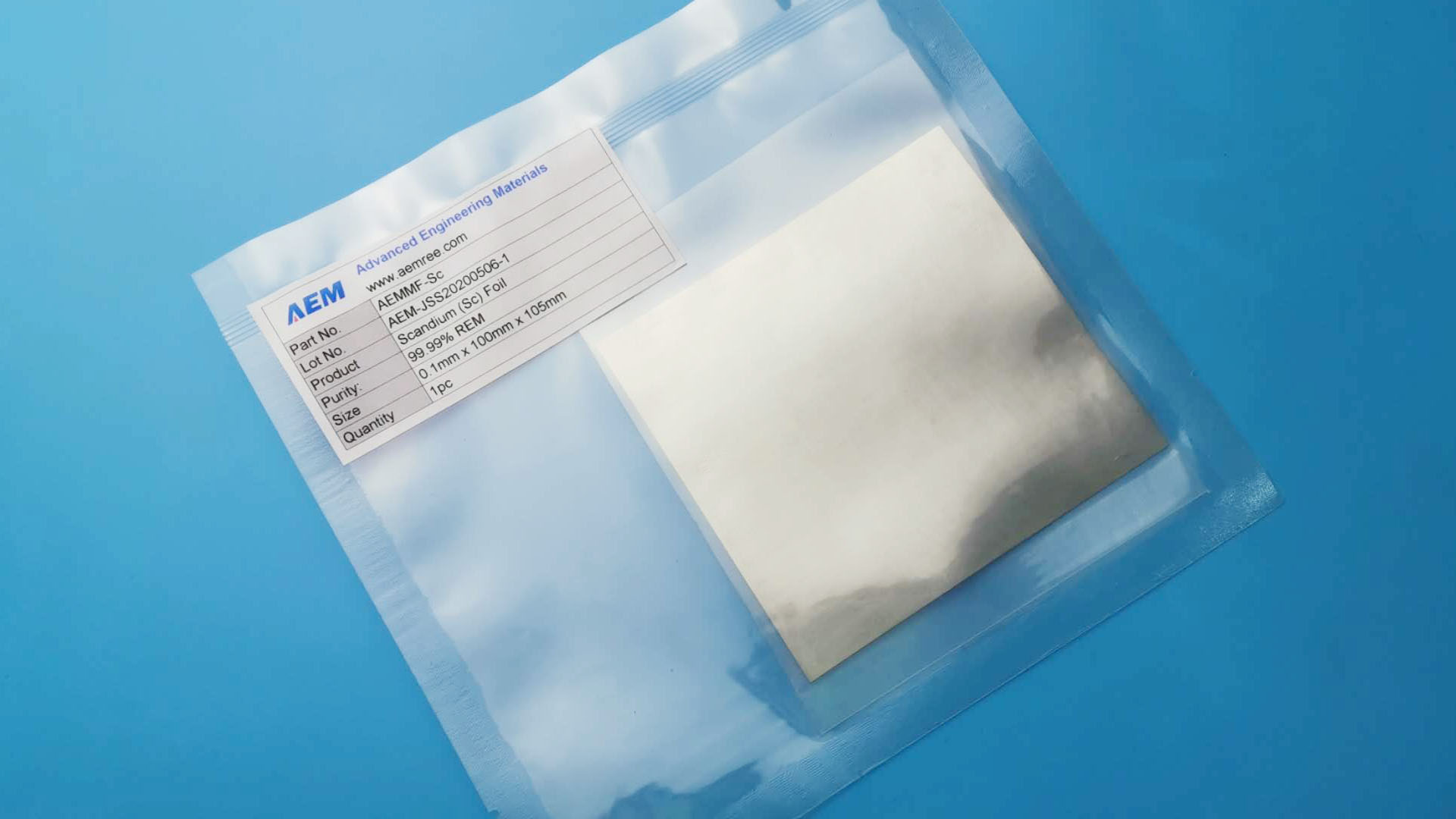

Scandium Sputtering Target (Sc) Video

Date: 2021-09-15

Abstract: Scandium Sputtering Target.Brand: AEM Deposition. Purity: 99.99% REM. Size: 0.1 x 100 x 105 mm. Application: • To produce scandium alloys. • Application in new lightning source. • Reagent for other compounds.• Application in laser

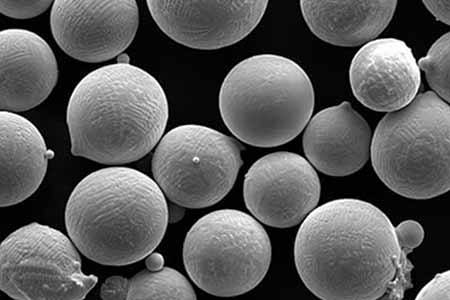

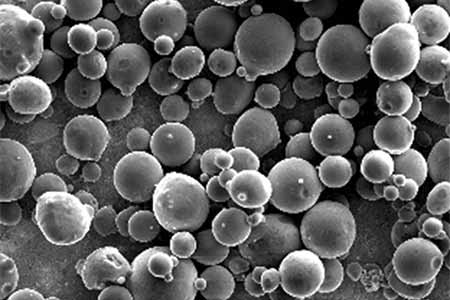

Application of Aluminum Powder and Aluminum Alloy Powder

Date: 2021-09-20

Abstract: Aluminum powder is a kind of silver white metal powder, which can be used to make paints, inks, pigments and fireworks. It can also be used as an additive of porous concrete. Aluminum powder can also be used for treatment and medical supplies. In addition, aluminum powder can also be used in the automobile and aircraft industry. Aluminum powder can be divided into spherical aluminum powder, irregular aluminum powder and aluminum alloy powder.

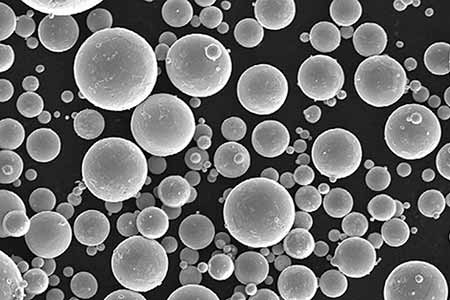

Application of Copper Powder and Copper Alloy Powder

Date: 2021-09-21

Abstract: Copper powder is a kind of metal powder with red luster. Copper powder can be widely used in powder metallurgy, electric carbon products, electronic materials, metal coatings, chemical catalysts, filters, heat pipes and other mechanical and electrical parts and electronic aviation fields. Copper powder includes electrolytic copper powder, atomized copper powder and copper alloy powder. The specific classification and application are as follows:

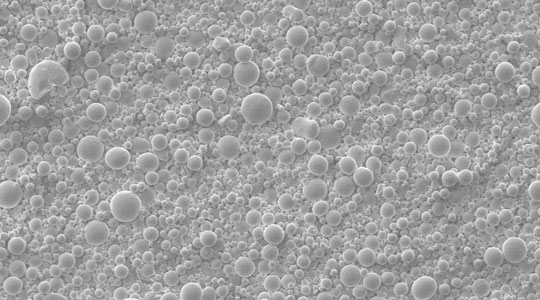

SNC / EG / UHA / UHD Ultrafine Iron Powder

Date: 2021-09-21

Abstract: Iron powder refers to iron particle powder with size less than 1mm. Its color is black. Iron powder is the main raw material of powder metallurgy. According to the particle size, iron powder can be divided into five grades: coarse powder, medium powder, fine powder, fine powder and ultra-fine powder. Iron powder with particle size of 150-500 μm is coarse powder, medium powder with particle size of 44-150 μm, fine powder with particle size of 10-44 μm, extremely fine powder with particle size of 0.5-10 μm, and ultra-fine powder with particle size of less than 0.5 μm.

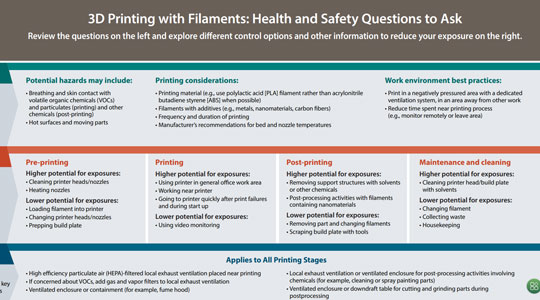

Could the Work Activity Cause Exposures When 3D Printing? What is the Likelihood of Exposure?

Date: 2021-09-21

Abstract: So when 3D printing, will work activities cause the exposure of organic chemicals and particles? Of course. Here, we list 17 potential for exposures during pre-printing, printing, post-printing, maintenance and cleaning. The details are as follows:

What Potential Hazards are Associated with 3D Printing? How to Prevent?

Date: 2021-09-21

Abstract: So, what are the potential hazards of 3D printing? How should we prevent it? According to NIOSH related documents, we can find these potential hazards in 3D printing:Potential hazards may include:• Breathing and skin contact with volatile organic chemicals (VOCs) and particulates (printing) and other chemicals (post-printing) • Hot surfaces and moving parts

3D Printing with Filaments: Health and Safety Questions to Ask

Date: 2021-09-21

Abstract: What potential hazards are associated with 3D printing? Are there known health effects from the filaments (for example, see safety data sheets)? What is the work environment like (for example, open or isolated area)?

Titanium Dioxide Sputtering Target (TiO2) Video

Date: 2021-09-15

Abstract: TiO2 Sputtering Target. Brand: AEM Deposition. Purity: 99.99%. Diameter: Φ40 x 50 mm. Application:• Decorative coating. • Flat Panel Displays. • Low-E Glass industry