+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Comparison of Six Methods for Making Silicon Nitride Powder

views, Updated: 2021-09-20

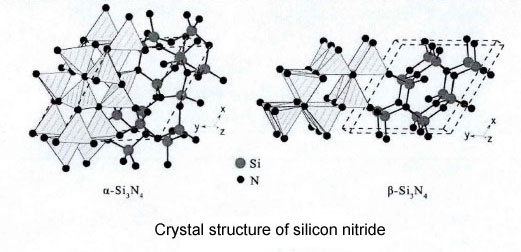

The basic principle of silicon nitride powder preparation is to produce silicon nitride powder with high purity and specific crystal phase (α phase or β phase). This preparation is done with the chemical reaction between nitrogen compounds and silicon compounds under suitable temperature and atmosphere.

In the preparation process, there are the following difficulties:

① The temperature window of powder preparation is narrow. If the temperature is too low, the reaction is incomplete. If the temperature is too high, the silicon nitride is easy to decompose.

② The preparation of powder requires high purity of the atmosphere. In fact, compared with the N element, the Si element prefers to combine with the O element. If oxygen is mixed in the atmosphere, Si powder is easy to "derail" to form silica.

③ It is challenging to obtain a specific crystal phase with high purity. The preparation method and process conditions, the type and amount of raw materials, and additives directly impact the crystal phase composition of silicon nitride products, which requires strict screening and control.

There are six methods to prepare silicon nitride powder. Their advantages and disadvantages are analyzed as follows:

Direct nitriding

Under the condition of 1300 ℃, the silicon powder with 0.125%Ca is added to react with nitrogen to form silicon nitride powder with α phase content up to 99%.

Advantages: Low cost, simple process, convenient for large-scale production.

Disadvantages: High-temperature and long time. The powder is easy to agglomerate, and impurities are easy to be introduced into the crushing process.

Carbothermal reduction

Silicon nitride powder is prepared from carbon powder and quartz powder at 1500 ℃ in a good nitrogen atmosphere.

Advantages: Low raw materials, simple process, continuous production.

Disadvantages: Product purity is not high, easy to contain impurities.

Gas phase method

Silicon nitride powder is prepared by the reaction of silicon tetrachloride and ammonia at 1100-1500 ℃.

Advantages: High purity and ultra-fine powder can be prepared.

Disadvantages: High cost, low yield, not easy to produce.

Self propagating method

Silicon nitride powder is prepared by a self propagating process with silicon powder and nitrogen as raw materials and ammonium chloride as an additive.

Advantages: Short time, high purity, and activity.

Disadvantages: High equipment requirements, uncontrollable process.

Thermal decomposition method

Silicon nitride powder can be prepared by heating the reaction product of silicon tetrachloride and excess anhydrous ammonia at high temperatures.

Advantages: High purity and ultra-fine powder can be prepared.

Disadvantages: Complex equipment and process, difficult to mass production.

Sol gel method

Using silica sol, urea, and carbon black as raw materials, 50-80nm silicon nitride powder is prepared at 1500 ℃.

Advantages: It is easy to produce high-purity and ultra-fine powder.

Disadvantages: High cost and long cycle.

For further questions, please email us at the below given email ID. If you need to buy the powder, you can also go to the powder page to buy it. We (AEM) provide tantalum powder, niobium powder, hafnium powder, molybdenum powder, chromium powder. The specific powder products are shown in the table below.

To purchase powder series products, please click the corresponding link to visit the page. You can email us for further communication and consultation at our email address, [email protected].

LATEST NEWS