+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

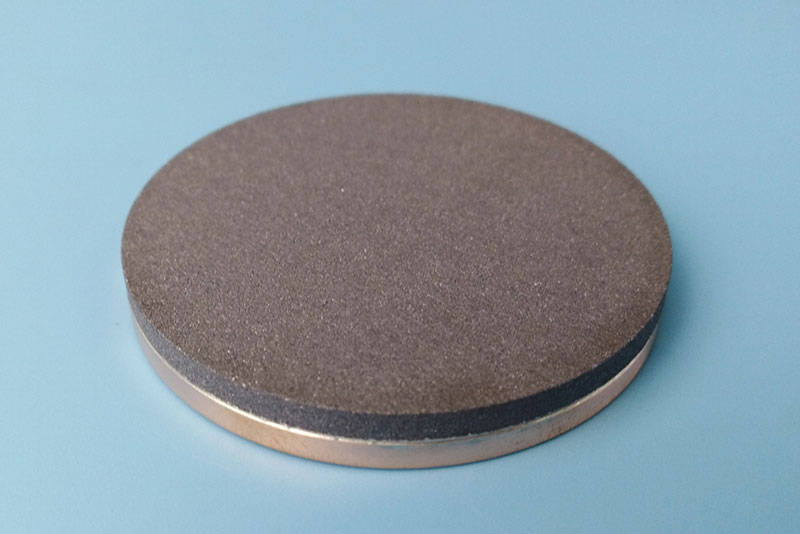

How to make CIGS Sputtering Targets production more effective?

In contrast to the high lateral homogeneity of thin-films deposited by sputtering, a sputtered target generally has an erosion profile that is not homogeneous – a result of different plasma densities. Consequently, the targets have to be replaced even if there is sufficient material on most of the target area. To overcome this limitation, targets with a varying outer diameter (named “dogbone” for rotary targets) or thickness is a solution to extend the target lifetime and increase the target exchange interval.

Sodium doped sputtering targets for more efficiency

With record conversion efficiencies of >20 % in the laboratory, CIGS has reached the same efficiency level as polycrystalline silicon. Two elements significantly impact CIGS cell efficiency: Iron (Fe) and sodium (Na). Whereas iron degrades the cell performance by introducing defects in the CIGS structure, sodium has the opposite effect: It concentrates defects at grain boundaries, which is a requirement for achieving high efficiencies. Low iron levels are only achieved by a high purity of the primary materials and a high-quality manufacturing process. Especially for molybdenum targets, the content can vary significantly.

The traditional way to introduce sodium into the CIGS absorber is utilizing a soda-lime-glass substrate. During the manufacturing process, sodium diffuses from the glass through the molybdenum back contact into the absorber layer, resulting in a sodium concentration in the order of 0.1 at%. However, this process's reproducibility and lateral homogeneity are low, and flexible substrates do not act as a sodium source.