+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

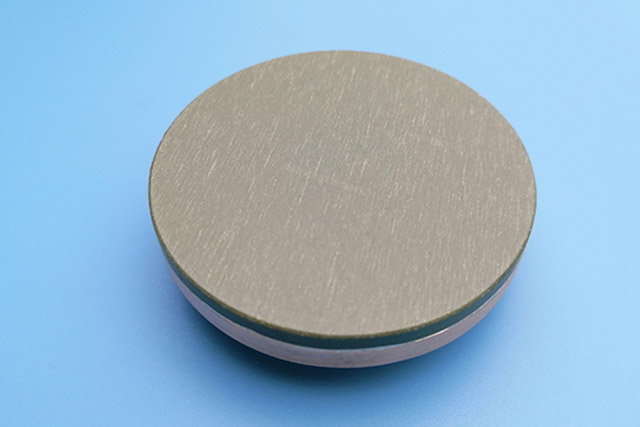

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Research and Markets of ITO (Indium Tin Oxide) Sputtering Targets

views, Updated: 2021-09-27

ITO (indium tin oxide) sputtering targets are core and critical materials in the electronic information area, mainly for the manufacture of flat-panel liquid crystal displays, touch panel, thin-film transistors, solar cells, transparent electrodes, and multifunction glass.

Currently, global ITO sputtering targets are almost monopolized by a small minority of enterprises such as JX Nippon Mining & Metals, Mitsui Mining, Tosoh, Samsung, Heraeus Umicore, in which Japanese and Korean companies account for nearly 80% of the market share. Chinese ITO sputtering target enterprises are still small in production scale and basically in trial production or small batch production for lack of core technology.

Global ITO sputtering target demand mainly comes from Japan, South Korea, mainland China, and other Asian countries, of which China accounts for more than 35% of the total. Benefited from the rapid development of downstream industries such as flat-panel displays, touch panels, global ITO sputtering target demand hit 2,500 tons or so by 2016, of which China's demand exceeds 40%, as it is estimated.

In addition to the supply & demand market influence, ITO sputtering targets are also directly affected by the raw material indium market. 70% of the global indium is used for ITO sputtering target production, but the indium resource is scarce, with basic reserves of merely 16,000 tons. While the current global annual consumption is about 1,400 tons, thus, long-term supply of indium suffers from bottlenecks.

China is rich in indium globally, whose basic reserves make up 62% of the world's total. Slow developments in downstream deep processing industries, especially in ITO sputtering target market, lead to substantial indium export in China, while ITO sputtering target present a high dependence on import.

To break bottlenecks in technology and capacity and utilize indium resources effectively, Chinese enterprises have accelerated R&D and introduces ITO sputtering technology, and multiple high-end ITO sputtering target localization projects have been launched.

LATEST NEWS