+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

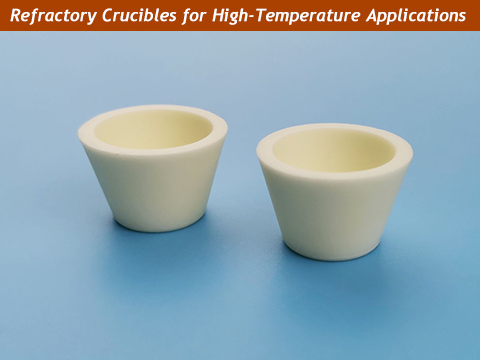

Refractory Crucibles: High-Performance Solutions for High Temperature Applications

views, Updated: 2026-01-23

Introduction

Refractory crucibles are vital in industries that work with very high temperatures, like metal refining and aerospace. These crucibles are designed to withstand extreme heat, making them perfect for melting and processing metals and other materials.

At AEM Deposition, we manufacture durable, heat-resistant crucibles using high-quality materials like graphite, alumina, zirconia, and tantalum. Our crucibles are built to meet the highest industry standards for performance and reliability.

In this blog, we'll explain the different types of refractory crucibles, their key benefits, and why choosing the right one is essential for your operations.

1. What Are Refractory Crucibles?

Refractory crucibles are specially designed containers built to handle extremely high temperatures. They are made from materials that can resist heat without breaking down, making them essential for industries like metal refining, glass manufacturing, and scientific research.

These crucibles are used to melt or hold materials, such as metals, chemicals, and other substances, at high temperatures. Their main job is to safely contain these materials during processes that require precise and controlled heating. What makes refractory crucibles stand out is their ability to maintain their strength and shape even in extreme conditions, where regular containers would melt or break.

In many industries, processes like metal casting or material testing require temperatures over 1000°C (1832°F). Regular containers can’t withstand this heat, which is where refractory crucibles come in. Made from heat-resistant materials like graphite, alumina, zirconia, and tantalum, these crucibles are designed to handle these extreme temperatures, ensuring operations continue safely and smoothly.

Refractory crucibles also provide excellent thermal stability. This means they help distribute heat evenly, preventing hot spots that could damage the materials inside. Even heating is critical to ensure materials melt evenly and maintain their quality.

In short, refractory crucibles are vital tools for industries that deal with high temperatures. They ensure materials are safely processed at temperatures that would destroy regular containers.

2. Types of Refractory Crucibles and Their Materials

Refractory crucibles are made from different materials, each designed to perform well in specific high-temperature conditions. The material used in a crucible plays a major role in its ability to handle extreme heat and the type of materials it can safely process. Let’s explore the most common types of refractory crucibles and the materials they are made from:

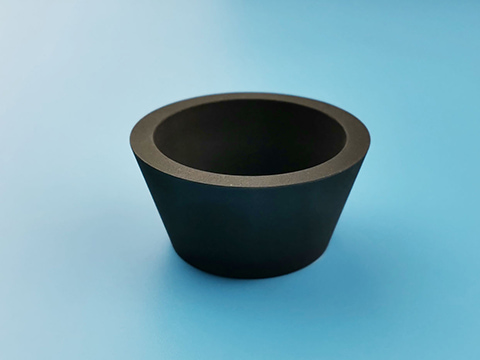

Graphite Crucibles

Graphite crucibles are widely used for melting precious metals like gold, silver, and aluminum. Graphite is known for its excellent ability to conduct heat, which helps distribute heat evenly inside the crucible. This ensures a smooth melting process without hot spots that could cause issues.

- Key Benefits: Graphite crucibles are lightweight, durable, and can resist thermal shock. They can handle temperatures up to 3000°C, making them ideal for high-heat processes.

- Common Uses: Metal casting, gold refining, and aluminum melting.

Alumina (Al₂O₃) Crucibles

Alumina, or aluminum oxide, is one of the most heat-resistant materials available, able to withstand temperatures up to 1750°C. Alumina crucibles are great for high-purity applications and are often used in industries like glass manufacturing and ceramics.

- Key Benefits: Alumina crucibles offer excellent chemical resistance and help maintain the purity of materials being processed, making them perfect for reactive or delicate materials.

- Common Uses: Glass production, ceramic testing, and chemical processes requiring high purity.

Zirconia (ZrO₂) Crucibles

Zirconia crucibles are designed for extremely high temperatures, capable of withstanding heat above 2000°C. Zirconia is known for its strength, durability, and resistance to thermal shock, which makes it suitable for environments where both high heat and sudden temperature changes are common.

- Key Benefits: Zirconia crucibles are highly durable and resistant to cracking under sudden temperature shifts, making them reliable for tough applications.

- Common Uses: High-temperature metal processing, metallurgy, and material research.

Tantalum (Ta) Crucibles

Tantalum crucibles are known for their ability to resist corrosion, especially when exposed to strong acids. With a high melting point of around 3020°C, tantalum is ideal for extreme temperatures and chemical environments.

- Key Benefits: Tantalum crucibles are resistant to corrosion and oxidation, making them perfect for handling reactive chemicals and metals under high heat.

- Common Uses: Aerospace, electronics, and chemical processing, where both high temperatures and corrosive substances are involved.

3. How to Choose the Right Refractory Crucible for Your Industry

Choosing the right refractory crucible is crucial for ensuring efficient and reliable high-temperature operations. The material, size, and design of the crucible can directly impact your production quality, efficiency, and operational costs. Here’s a guide to help you select the best refractory crucible based on your industry and specific needs.

1. Understand the Materials You’re Working With

The first step in choosing the right crucible is understanding the materials you plan to process. Different metals, chemicals, and alloys require specific types of refractory materials to ensure safe and efficient handling. Here’s a breakdown of how to choose based on your material:

- Metals: If you’re working with metals like gold, silver, or aluminum, graphite crucibles are an ideal choice. They have excellent heat conductivity, ensuring even melting. For metals with higher melting points, such as steel or titanium, alumina (Al₂O₃) or zirconia (ZrO₂) crucibles are better options due to their ability to withstand higher temperatures and maintain integrity under heat.

- Chemicals: In chemical processing, particularly with reactive chemicals, tantalum (Ta) crucibles are a great option due to their resistance to corrosion and high melting point. Zirconia also works well for handling highly corrosive materials.

- Glass and Ceramics: For glass manufacturing or ceramic testing, alumina and zirconia are commonly used. These materials provide excellent resistance to the extreme temperatures and chemical reactions involved in these processes.

2. Consider the Temperature Range

Different materials have different temperature resistance capabilities. The temperature your crucible will be exposed to plays a crucial role in selecting the right material:- Graphite Crucibles: Typically, graphite can handle temperatures up to 3000°C and is great for applications where high thermal conductivity is necessary. It’s ideal for metal melting and refining precious metals.

- Alumina (Al₂O₃): Suitable for high temperatures up to 1750°C, making it an excellent choice for applications like glass production and ceramic testing, where high heat is required but not at the extreme levels of graphite.

- Zirconia (ZrO₂): With its ability to withstand temperatures above 2000°C, zirconia is perfect for applications that involve extreme heat, like superalloy production or metallurgical research.

- Tantalum (Ta): Tantalum crucibles are capable of handling temperatures of up to 3020°C, making them ideal for highly demanding chemical processing applications where both high heat and corrosion resistance are needed.

3. Consider Thermal Shock Resistance

Thermal shock resistance is an important factor to consider when choosing a refractory crucible. Industries that require rapid heating and cooling cycles need crucibles that can withstand these changes without cracking or breaking.- Graphite Crucibles: Known for their excellent thermal shock resistance, graphite crucibles can handle quick temperature changes, making them ideal for applications like metal casting where rapid heating and cooling are common.

- Alumina and Zirconia Crucibles: Both materials have good thermal shock resistance but may be more prone to cracking if exposed to extreme temperature changes in short periods. They are ideal for glass and ceramics, where the heating process is generally more gradual.

- Tantalum Crucibles: Tantalum is also known for its good thermal shock resistance, making it a solid choice for environments with frequent temperature fluctuations.

4. Evaluate Chemical Resistance

Depending on the materials you’re processing, you may need a crucible with excellent chemical resistance to prevent contamination or degradation of the crucible itself.- Tantalum Crucibles: Tantalum is highly resistant to acids, alkalis, and other corrosive substances, making it an excellent choice for chemical processing and highly reactive metal handling.

- Zirconia Crucibles: Zirconia is chemically stable and resistant to most acids and slags, making it ideal for use in metallurgy and ceramics, where exposure to harsh chemicals is common.

- Graphite Crucibles: While graphite has good resistance to many non-oxidizing chemicals, it is not as resistant to oxidation or certain acidic environments. However, it is highly suitable for processes where chemical interactions are minimal, such as gold and silver refining.

5. Consider the Crucible Size and Shape

The size and shape of the crucible depend on the volume of material you plan to melt or process. Larger operations may require larger crucibles, while smaller operations may benefit from compact, more efficient crucibles.- Standard Sizes: Most crucibles come in a range of sizes. At AEM Deposition, we offer crucibles from 40 mm to 150 mm (1.57 inches to 5.91 inches), but we can customize the size to meet specific needs.

- Custom Shapes: If your application requires a specific shape or design, such as a particular height or diameter, we can provide customized crucibles. This flexibility ensures that the crucible fits perfectly into your system for optimal performance.

6. Price vs. Performance

While performance is crucial, cost is always a consideration. Refractory crucibles made from materials like graphite and alumina tend to be more affordable, while zirconia and tantalum may come at a higher price point due to their superior temperature and chemical resistance.- Graphite Crucibles: Generally the most cost-effective option for basic melting operations.

- Alumina and Zirconia Crucibles: Offer great performance at a moderate price point, ideal for industries like glass production and ceramics.

- Tantalum Crucibles: The most expensive, but they offer unmatched chemical and temperature resistance, making them perfect for highly demanding chemical processes.

Final Thoughts

Choosing the right refractory crucible is crucial for maximizing the efficiency, safety, and quality of your high-temperature operations. By understanding the specific needs of your industry, including material types, temperature ranges, and other critical factors, you can select the right crucible to achieve optimal performance.At AEM Deposition, we offer a wide range of high-quality refractory crucibles tailored to meet the specific requirements of your industry. Whether you need a custom size, advanced chemical resistance, or superior heat resistance, our team is here to provide expert advice and the perfect solution for your needs.

4. Why Choose AEM Deposition for Your Refractory Crucibles?

At AEM Deposition, we provide high-quality refractory crucibles designed for your specific needs. Here’s why we’re the best choice for your business:

Custom Solutions Just for You

We offer customizable crucibles tailored to your exact needs, ensuring that you’re only paying for what you truly require. Whether it’s the size, material, or specific design, we work with you to find a solution that fits your budget without sacrificing performance. This flexibility ensures you get the best value for your investment.

Quality You Can Trust

Using the latest technology, we create precise, high-quality crucibles that meet your exact specifications, ensuring reliable performance even in the most extreme conditions.Our crucibles deliver top performance with:

- High-Temperature Resistance: Withstand temperatures from 1600°C to 3200°C.

- Chemical Resistance: Excellent protection against acid, alkali, and slag corrosion.

- Precision: Tolerances of ±2mm for inner diameter and ±3mm for height.

Affordable Solutions

While our crucibles are priced competitively, we don’t cut corners on quality. As a direct factory in China, we can save you 20-30% compared to other suppliers, offering high-quality products at competitive prices.

Conclusion

Choosing the right refractory crucible is key to making sure your high-temperature processes run smoothly. At AEM Deposition, we offer high-quality crucibles made from materials like graphite, alumina, zirconia, and tantalum. These crucibles are perfect for industries like metal refining, glass production, and research.

We provide customizable crucibles that meet your specific needs. With our advanced manufacturing techniques, we ensure that each crucible is durable and can handle high temperatures. Whether you need precise sizes or reliable performance, AEM Deposition has the right solution for you.

We offer great products at competitive prices, and we're always here to support you.

Get in touch with us today to find out how our refractory crucibles can help improve your operations.

LATEST NEWS