PVD Coating and PVD Materials

views, Updated: 2023-01-05

Brief Introduction of Physical Vapour Deposition (PVD)?

Physical vapor deposition (PVD) is a thin-film coating process that produces coatings of pure metals, metallic alloys, and ceramics with a thickness usually in the range 1 to 10µm. As its name implies, physical vapor deposition involves physically depositing atoms, ions, or molecules of a coating species onto a substrate.

There are three main types of PVD undertaken in a chamber containing a controlled atmosphere at reduced pressure (0.1 to 1 N/m 2). All three techniques can be used for the direct deposition of a material or for 'reactive' use in which chemical reaction occurs in the vapor/plasma phase between atoms of the coating material and 'reactive' gases.

1. Thermal evaporation. Thermal evaporation uses the heating of a material to form a vapor, which condenses on a substrate to form the coating. Heating is achieved by various methods, including hot filament, electrical resistance, electron or laser beam, and electric arc.

2. Sputtering. Sputtering involves the electrical generation of a plasma between the coating species and the substrate.

3. Ion plating. Ion plating is essentially a combination of thermal evaporation and sputtering.

PVD is a batch coating process with typical cycle times of 1 to 3 hours, depending on the material being deposited and the desired coating thickness. Common coating rates are 50 to 500µm/hr, depending on the technique. Coated components do not require additional machining or heat treatment. The temperature of the substrate being coated is typically in the range of 200-400°C, considerably lower than temperatures associated with CVD (chemical vapor deposition, the other thin-film process). PVD is a line-of-sight process and requires the substrate surface to be easily accessible. Some components are rotated to produce even coatings.

Applications of PVD Coating

The most common PVD coating is TiN, widely used to provide wear protection. Other materials deposited as single or multi-layer coatings include aluminides, MCrAlYs, Al2O3, ZrO2, ZrN, CrN, TiCN, TiAlN, and diamond-like coatings (DLCs). There are many uses for coatings prepared by PVD, include:

1. Aluminium tracks and ceramic resistors for electronic circuitry,

2. Anti-reflective ceramic coatings for optics. Decorative coatings on plastics,

3. Corrosion resistant coatings on gas turbine blades,

4. Wear prevention coatings for machine and press tools.

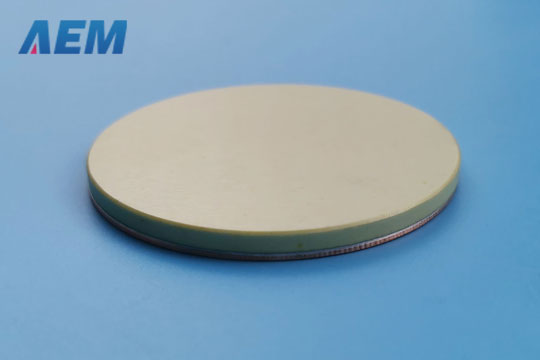

What can AEM Deposition Do for PVD Coating?

AEM Deposition is an international company involved in the R & D, manufacturing, and sales of all kinds of Physical Vapor Deposition materials. We provide all materials sputtering targets and evaporation materials for each client. We have 10+ years of experience to manufacture and export deposition materials. If you have any questions or product inquiry, don't hesitate to contact us anytime.

LATEST NEWS

2025-05-29

2025-05-22

2025-05-09

2025-04-09

2025-04-09

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]