Aluminum Sputtering Targets (Al)

| Material Type | Aluminum |

| Symbol | Al |

| Atomic Weight | 26.9815386 |

| Atomic Number | 13 |

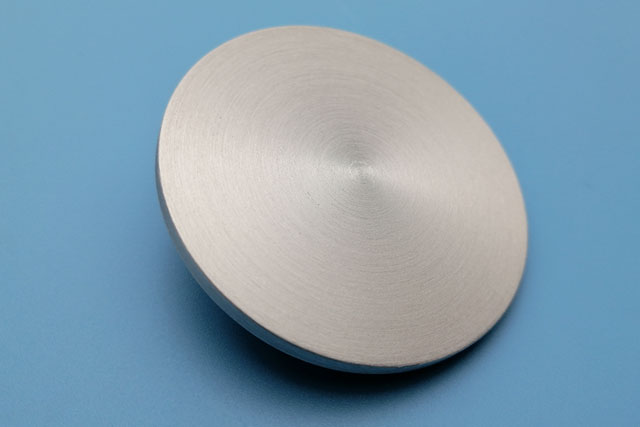

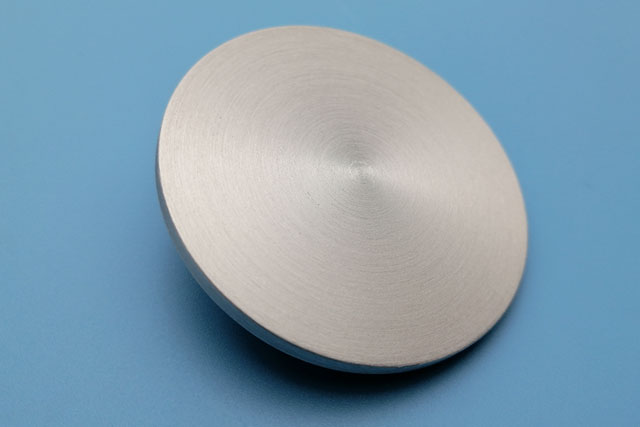

| Color/Appearance | Silvery, Metallic |

| Thermal Conductivity | 235 W/m.K |

| Melting Point (°C) | 660 |

| Coefficient of Thermal Expansion | 23.1 x 10-6/K |

| Theoretical Density (g/cc) | 2.7 |

| Z Ratio | 1.08 |

| Sputter | DC |

|

Max Power Density* (Watts/Square Inch) |

150 |

| Type of Bond | Indium, Elastomer |

| Comments | Alloys W/Mo/Ta. Flash evap or use BN crucible. |

What is Aluminum Sputtering Target

Aluminum sputtering target is a popular material because it can be easily deposited onto a wide range of substrates, including glass, silicon, and metals. When sputter-deposited, aluminum forms a smooth, hard coating that is highly resistant to corrosion and wear. Additionally, aluminum coatings are often used to improve the appearance of objects by providing a shiny, reflective surface.

In addition to its superior properties, aluminum is also less expensive compared to other sputtering target materials. For these reasons, aluminum sputtering target are widely used in many applications.

Aluminum is a metallic material that is silver-white in color. It can be found in kitchen utensils, cars, streetlights, and aluminum foil on food packaging. Although it is not very strong, it is a good conductor of heat and electricity.

If evaporated in a vacuum, aluminum forms a reflective coating that is used on telescopes, automotive headlamps, mirrors, and toys. The aluminum sputtering target is widely used in the aerospace, automotive lighting, OLED, and optical industries. Some high purity aluminum targets are used in the semiconductor chip, flat panel display, and solar cell industries.

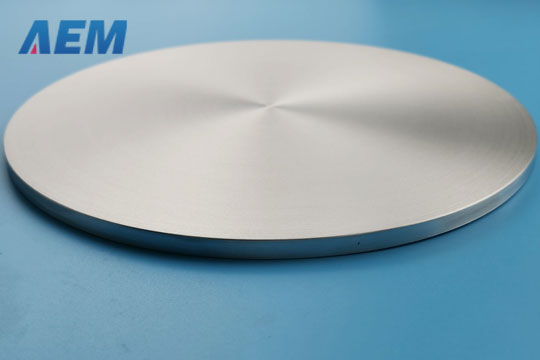

Aluminum Sputtering Targets Specification

Purity: 99.99-99.9995%;

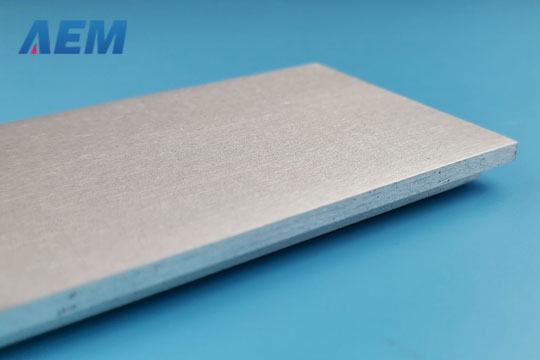

Target Type: Planar & Rotary sputtering targets

Circular: Diameter <= 16 inch, Thickness >= 1mm;

Block: Length <= 48 inch, Width <= 15.75 inch, Thickness >= 1mm.

If you're looking for Aluminum sputtering targets, we'll work with you to find the best solution for your needs.

Aluminum Sputtering Targets Analysis

More Information on Aluminum Sputtering Targets

|

Applications • Electronics • Semiconductor • Flat panel displays |

Features • Competitive pricing • High purity • Grain refined, Engineered microstructure ( the average grain size < 300 um) • Semiconductor grade |

|

Manufacturing Process • Melting, Zone melting • Analysis GDMS,ICP-OES • Analysis Casting & Grain refinement • Cleaning and final packaging-Cleaned for use in vacuum Protection from environmental contaminants Protection during shipment |

Options • 99.99% minimum purity • Aluminum alloys sputtering targets Al2O3, Ni/Cr/Al/Si, Al/Nd, Y3Al5O12, In2O3/Al2O3/ZnO, Al/Si/Cu, Al/Cu, CuAlO2, AlN, Ni3/Al, Fe/Al, Al/Sc • Smaller sizes also available for R&D applications • Sputtering target bonding service |

Related Products of Aluminum Sputtering Targets

|

|

||

|

Evaporation Materials |

Crucibles Alumina Crucible |

Metal Powders Aluminium Powder |

Click to download datasheet about Aluminum Sputtering Targets (Al)

Click to download datasheet about Aluminum Sputtering Targets (Al)

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).