+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

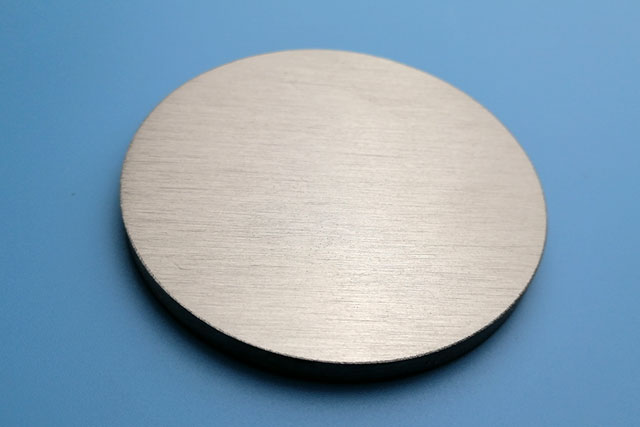

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Introduction of Sputter Deposition

Sputtering (sputter deposition) is a method used to create Thin-films and is a type of PHYSICAL VAPOR DEPOSITION. Unlike some other vapor deposition methods, the material does not melt. Instead, atoms from the source material (sputtering targets) are ejected by momentum transfer from a bombarding particle, typically a gaseous ion. An advantage of this process is that sputter-ejected atoms have kinetic energies significantly higher than evaporated materials.

In the gaseous ion sputtering configuration, the substrate that is coated is set inside a vacuum chamber. Air is removed from the chamber, and an inert gas is pumped in at low pressure. Inert gas is used because it does not react chemically to the target material. The most common (and cheapest) sputtering gas is argon (Ar), followed by krypton (Kr), xenon (Xe), neon (Ne), and nitrogen (N2). Light atomic weight gases such as hydrogen (H) and helium (He) result in negligible sputtering.

The basic sputtering methods are planar magnetron, cylindrical magnetron, high-power impulse magnetron, diode, and ion beam sputtering.

Commercial Applications of Sputter Deposition:

The Sequence of Sputter Deposition Process

AEM Deposition is a senior sputtering targets manufacturer, and we have over 10 years of experience to manufacture and sale all kinds of sputtering targets. If you need anything, just send an email to us.