+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

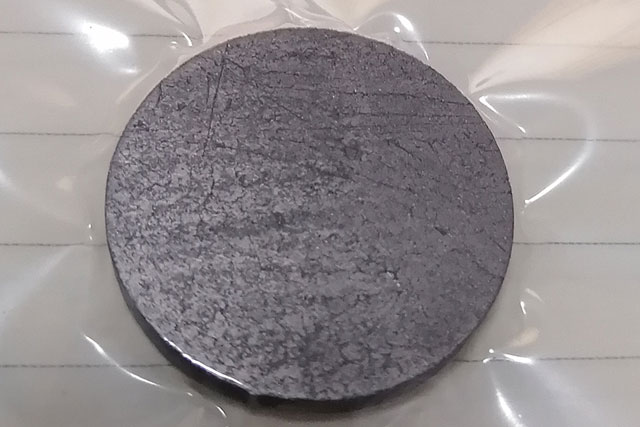

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Rotatable Sputtering Targets Provided by AEM Deposition

We all know, Compared to standard planar sputtering targets, our rotatable sputtering targets greatly increase material utilization for thin-film deposition of large areas. This savings is especially valuable for photovoltaic and solar power applications and reflective coatings in mirrors and high-temperature coatings.

As the world-leading producer of thin-film deposition materials, AEM Deposition provides:

Cylindrical sputtering targets have many advantages over planar as below:

Rotatable sputtering targets increase run time and are more cost-effective for high volume processes for large area coating. AEM Deposition supplies a range of precious and non-precious metals as well as ceramic and inorganic targets with customized chemistries:

Supporting photovoltaic and solar powder applications:

AEM Deposition also supports the photovoltaic and solar power industry as well as high-temperature and reflective coating applications with rotatable sputtering targets as well as multiple materials including: