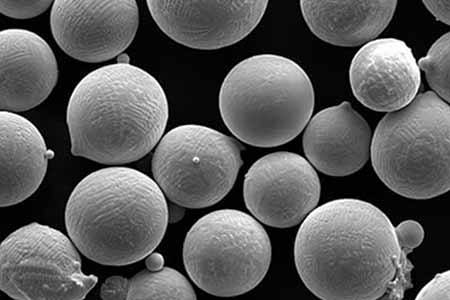

Iron Powder

Iron Powder

Iron powder is a kind of improtant metal powder for powder metallurgy,and it requires a large quantity of Fe powder accounts for 85% of the toatl metal powder. The Iron powder mainly used in manufacturing machine parts.

Iron-based alloy powder can be used on the working layer of abrasion resistant anticorrosive parts, such as hydraulic turbine blade, nozzle, wearing ring, hydraulic rod. The stainless steel powder has good sphericity configuration with low oxygen content, high hardness and good toughness.

The iron powder should be stored in a cool, dry, well ventilated warehouse and kept away from fire and other heat sources. Relative humidity should remain below 75%. The packing must be sealed, do not be affected with damp . It should be kept apart from alkali, alcohol, and it should avoid mixed reservoir by all means. The storage area should be equipped with the right material in the case of leakage.

Where to buy iron powder? AEM can supply diffferent kinds of high purity Iron Metal Powder for sale. If you did not find the sizes or compositions you need, please contact us by email. We have customized sizes and compositions according to customer's requests.

Iron Metal powder

| Grade | Product Name | Chemical Composition | Particle Size | Apparent Density (g/cm3) |

|---|---|---|---|---|

| Fe-1 | Iron powder |

Fe: ≥ 99.0% Other: ≤ 1.0% |

-200 mesh customed sizes avaliable |

- |

| Fe-2 | Iron powder |

Fe: ≥ 99.0% Other: ≤ 1.0% |

2- 4 um, D50: 18-27 um customized sizes avaliable |

0.5-15 |

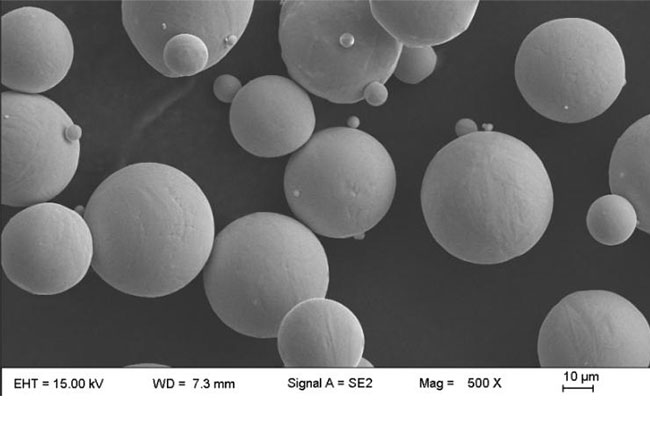

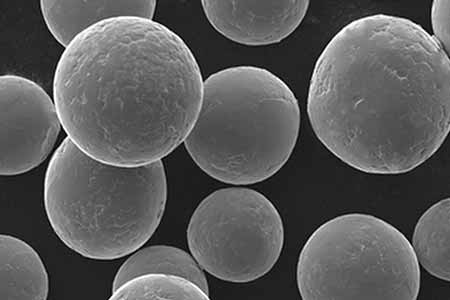

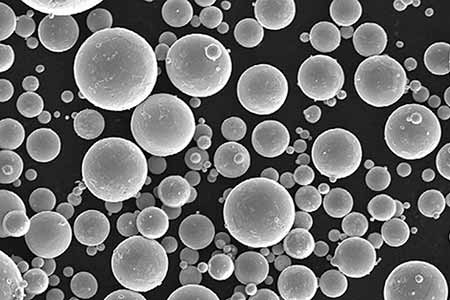

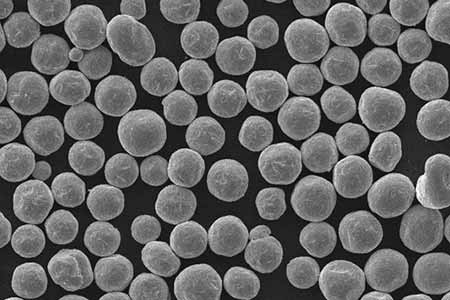

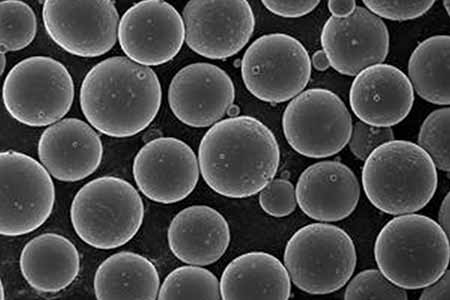

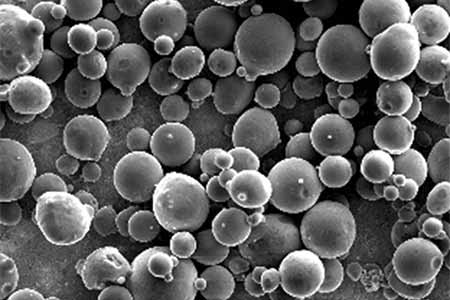

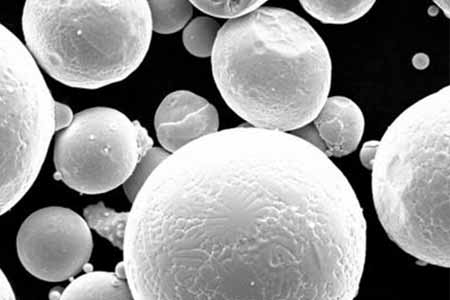

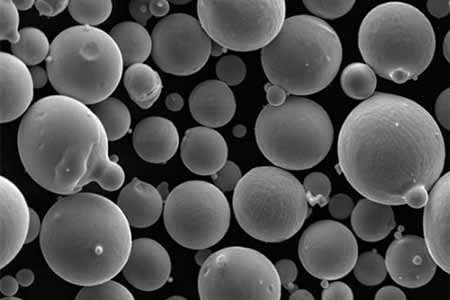

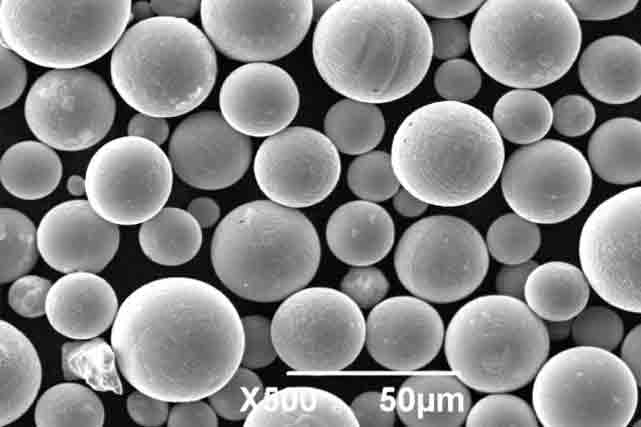

Spherical Iron Based Alloy Powder

Iron-based alloy powder can be used on the working layer of abrasion resistant anticorrosive parts, such as hydraulic turbine blade, nozzle, wearing ring, hydraulic rod. The stainless steel powder has good sphericity configuration with low oxygen content, high hardness and good toughness.

AEM can supply diffferent kinds of Iron-Based Alloy Powder in high purity. If you can't find the sizes or compositions you need, please contact us by email. We have customized sizes and compositions according to customer's requests.

Grade:

Stainless steel powder: 304, 316L, 410L, 15-5PH, 17-4PH, 2Cr13

High-strength steel powder: A100, 300M, 30CrMnSiA, 40CrMnSiMoVA

Tool steel powder: 18Ni300, H13, M2, M35, M42, T15, 2030, S390

Iron-nickel alloy powder: Invar 36

Standard: GB/T 3077, GB/T 1299, GB/T 1480, GB/T 5329, GB/T 8180

Particle Size: 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm

Shape: Spherical, Ψ0≥0.85

Appearance: Gray

3D Printing Application: SLM, LMD

Other Application: PM, MIN, HIP, SP, Welding repair

Package: Vacuum packaging (Aluminum foil bag) or argon-filled protective packaging (Aluminum bottle)

Chemical Composition of Iron Based Alloy Powder

| Grade | Chemical Composition (wt.%) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Mn | Mo | Si | Nb | Cu | Co | Ti | Al | V | P | O | N | S | Fe | |

| 304 | ≤0.07 | 17-19 | 8-10 | ≤2 | ≤1 | ≤0.035 | ≤0.03 | Bal. | |||||||||

| 304L | ≤0.03 | 18-20 | 8-10 | ≤2 | ≤1 | ≤0.035 | ≤0.03 | Bal. | |||||||||

| 316 | ≤0.08 | 16-18.50 | 10-14 | ≤2 | 2-3 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||

| 316L | ≤0.03 | 16-18 | 12-15 | ≤2 | 2-3 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||

| 410 | ≤0.15 | 11.5-13.5 | ≤1 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||||

| 420 | 1.06-0.25 | 12-14 | ≤1 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||||

| 430 | ≤0.12 | 16-18 | ≤0.6 | ≤1 | ≤0.75 | ≤0.04 | ≤0.04 | Bal. | |||||||||

| 630 | ≤0.07 | 15.5-17.5 | 6.5-7.5 | ≤1 | ≤1 | 0.15-0.45 | 3-5 | ≤0.035 | ≤0.03 | Bal. | |||||||

| 17-4PH | ≤0.07 | 15.5-17.5 | 3-5 | ≤1 | ≤1 | 0.15-0.45 | 3-5 | ≤0.035 | ≤0.03 | Bal. | |||||||

| 15-5PH | ≤0.07 | 14-15.5 | ≤1 | ≤1 | 0.15-0.45 | 2.5-4.5 | ≤0.04 | ≤0.05 | 3.5-5.5 | ≤0.03 | Bal. | ||||||

| 2Cr13 | 0.16-0.25 | 12-14 | ≤1 | ≤1 | ≤0.035 | ≤0.05 | ≤0.6 | ≤0.03 | Bal. | ||||||||

| SCM415 | 0.13-0.18 | 0.9-1.2 | 0.6-0.85 | 0.15-0.3 | 0.15-0.35 | ≤0.04 | ≤0.03 | Bal. | |||||||||

| S301 | ≤0.15 | 16-18 | 6-8 | ≤2 | ≤1 | ≤0.045 | ≤0.05 | ≤0.1 | ≤0.03 | Bal. | |||||||

| S310 | ≤0.08 | 24-26 | 19-22 | ≤2 | ≤1.5 | ≤0.045 | ≤0.05 | ≤0.03 | Bal. | ||||||||

| S220 | ≤0.03 | 22-23 | 4.5-6.5 | ≤2 | 3-3.5 | ≤1 | ≤0.03 | ≤0.05 | 0.14-0.2 | ≤0.02 | Bal. | ||||||

| 18Ni300 | ≤0.03 | ≤0.3 | 17-19 | ≤0.1 | 4.5-5.2 | ≤0.1 | 8.5-9.5 | 0.6-0.8 | 0.05-0.15 | ≤0.01 | ≤0.05 | ≤0.01 | Bal. | ||||

| H13 | 0.32-0.45 | 4.75-5.5 | 0.2-0.5 | 1.1-1.75 | 0.8-1.2 | 0.8-1.2 | ≤0.03 | ≤0.05 | ≤0.03 | Bal. | |||||||

| 1.2709 | ≤0.03 | ≤0.25 | 17-19 | ≤0.15 | 4.5-5.2 | ≤0.41 | 8.5-10 | 0.8-1.2 | ≤0.01 | ≤0.05 | ≤0.01 | Bal. | |||||

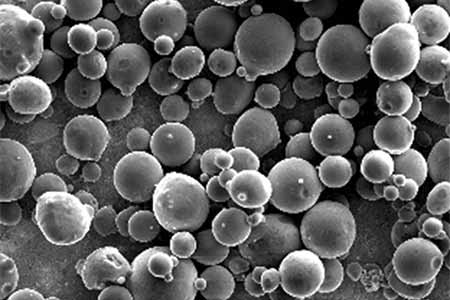

Self-fusing Iron Base Alloy Powder

Products Series

| Grade | Hardness (HRC) | Chemical Composition | Particle (mesh) | Application | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | Mo | Ni | Mn | B | Other | ||||||

| Fe1 | 35-40 | 0.15 | 22 | 4.5 | Bal. | 2 | 13 | 1.6 | 100/270 | Valve | ||||

| Fe2 | 38-44 | 0.15 | 22 | 4.5 | Bal. | 2 | 10 | 1.8 | 100/270 | Valve seat | ||||

| Fe5 | 62-67 | 4.5 | 40 | 1 | Bal. | 0.97 | 1.8 | 100/270 | Drilling pipe joint | |||||

| Fe90 | 50-55 | 0.15 | 13.5 | 1.3 | Bal. | 1.6 | 100/270 | Drilling pipe joint | ||||||

| Fe6 | 58-60 | 0.8 | 7.5 | 2 | Bal. | 32 | 4 | 100/270 | Fan blades | |||||

| Fe45 | 40-46 | 0.6 | 7.5 | 2 | Bal. | 22 | 3 | 100/270 | Paper-making machines | |||||

| Fe304 | HB190 | 0.03 | 18 | 0.1 | Bal. | 10 | 0.3 | 100/270 | Paper-making machines | |||||

| Fe316L | HB190 | 0.03 | 17 | 0.2 | Bal. | 2.5 | 12 | 0.5 | 100/270、300/500 | Paper-making machines | ||||

| Fe410L | HB220 | 0.03 | 12.5 | 0.5 | Bal. | 0.1 | 100/270、 300/500 | Pistons | ||||||

| JG-1 | 19 | 0.03 | 17 | 0.8 | Bal. | 0.3 | 1.3 | Pistons | ||||||

| JG-2 | 26 | 0.04 | 17 | 0.3 | Bal. | 0.2 | 2.6 | Pistons | ||||||

| JG-3 | 46 | 0.12 | 16.5 | 0.8 | Bal. | 0.9 | Pistons | |||||||

| JG-4 | 63 | 1 | 4 | 0.3 | Bal. | 5 | 0.3 | Pistons | ||||||

| Fe253 | 35 | 1.75 | 28 | 1.3 | Bal. | 4.5 | 16 | 0.8 | 100/270 | Engine Valve | ||||

| Fe253H | 40 | 2.1 | 28 | 1.2 | Bal. | 5.5 | 11.5 | 1 | 100/270 | Engine Valve | ||||

| Fe101 | 62 | 3.3 | 2 | 1 | Bal. | 5 | 1 | 1.4 | 20/300 | Extrusion barrels | ||||

| Fe102 | 62 | 2.7 | 2.8 | 1 | Bal. | 5.5 | 1 | 1.9 | 20/300 | Extrusion barrels | ||||

| Fe103 | 62 | 1.5 | 4.5 | 1 | Bal. | 7 | 1 | 2.9 | W:4.5 | 20/300 | Extrusion barrels | |||

| Fe104 | 60 | 1.7 | 4.5 | 1.5 | Bal. | 11 | 0.8 | 3 | 20/300 | Extrusion barrels | ||||

| Fe105 | 62 | 1.5 | 4.5 | 1.3 | Bal. | 1.5 | 12 | 1 | 2.8 | 20/300 | Extrusion barrels | |||

| Fe106 | 62 | 1.08 | 5.42 | 2.01 | Bal. | 27 | 0.89 | 3.08 | 20/300 | Extrusion barrels | ||||

| Fe107 | 62 | 1.36 | 6.25 | 1.56 | Bal. | 16.2 | 1.02 | 2.98 | 20/300 | Extrusion barrels | ||||

Related Powders of Iron Powder

| Tantalum Powder | |||

| More Powder |

Related Products of Iron Powder

|

Ceramic Sputtering Targets |

||

|

Evaporation Materials |

Crucibles N/A |

Metal Powders |

Click to download datasheet about Iron Powder

Click to download datasheet about Iron Powder

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).