Tungsten Powder

Tungsten Powder

Tungsten powder is the main raw material for processing Tungsten alloy. Pure Tungsten powder can be made into wire, rod, tube, plate and other processing materials and certain shape products. Tungsten powder mixed with other metal powder, can be made into all kinds of Tungsten alloy, such as Tungsten Cobalt alloy, Tungsten Rhenium alloy, Tungsten Copper alloy and high density Tungsten alloy.AEM provides tungsten powder and tungsten carbide powders in high quality with great density. Please contact us if you didn't find the powders you need. The powder sizes can be customized by your requests.

Tungsten Powder Feature

Application: Tungsten powder is widely used in the production of weight fillers, radiation shielding fillers and induction accelerators, etc.. The thin film surface of its polymer mixture is ideally suitable for radiation protection. The large particle size makes it an ideal heavy metal filler for injection-molding applications. The unique shape and the resulted high flow ability of the particles make it suitable for applications in metal spray industry. Another important application of Tungsten powder is made of Tungsten Carbide powder, and preparation of cemented carbide tools, such as turning, milling, drilling and molds etc.Chemical Composition of Tungsten Powder

|

Chemical Composition |

FW-1 |

FW-2 |

FW-3 |

|

|---|---|---|---|---|

|

W Content (%)≥ |

99.95 |

99.8 |

99.8 |

|

|

Other Elements (%) < |

Fe |

0.005 |

0.03 |

0.03 |

|

Al |

0.001 |

0.004 |

0.005 |

|

|

Mg |

0.002 |

0.005 |

0.01 |

|

|

Mn |

0.001 |

0.004 |

0.004 |

|

|

Ni |

0.001 |

0.002 |

0.004 |

|

|

As |

0.003 |

0.004 |

0.005 |

|

|

Pb |

0.0015 |

0.002 |

0.002 |

|

|

Bi |

0.0001 |

0.0005 |

0.0007 |

|

|

Sn |

0.0001 |

0.0005 |

0.0007 |

|

|

Sb |

0.0003 |

0.0005 |

0.0007 |

|

|

Cu |

0.0001 |

0.001 |

0.001 |

|

|

Ca |

0.0007 |

0.001 |

0.002 |

|

|

Mo |

0.002 |

0.002 |

0.004 |

|

|

K+Na |

0.005 |

0.005 |

0.01 |

|

|

P |

0.003 |

0.009 |

0.003 |

|

|

C |

0.005 |

0.004 |

0.004 |

|

|

O |

0.005 |

0.01 |

0.01 |

|

|

Special requirements to be agreed upon by the supplier and buyer |

||||

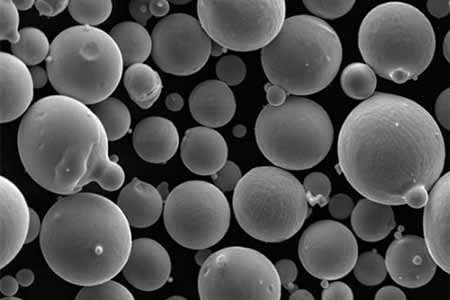

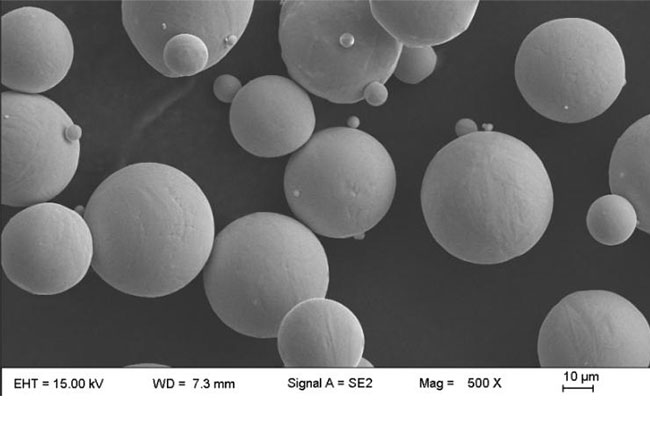

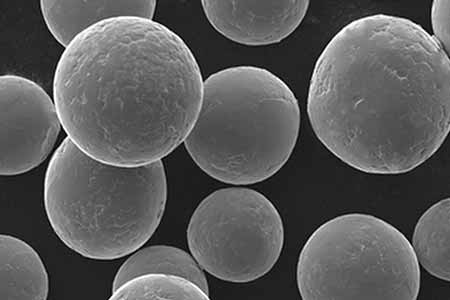

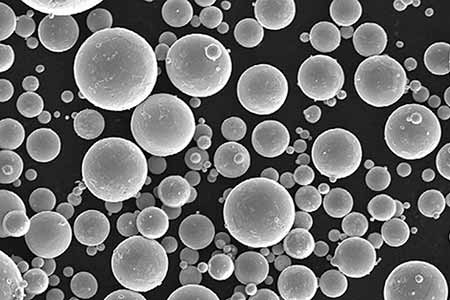

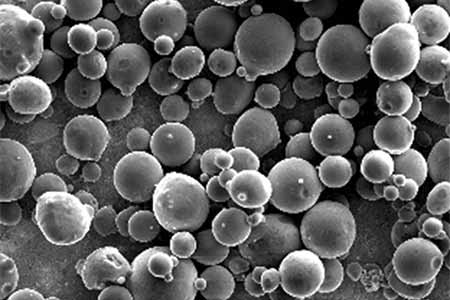

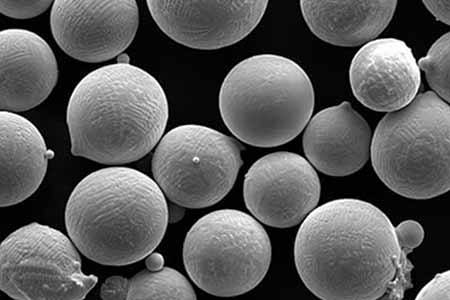

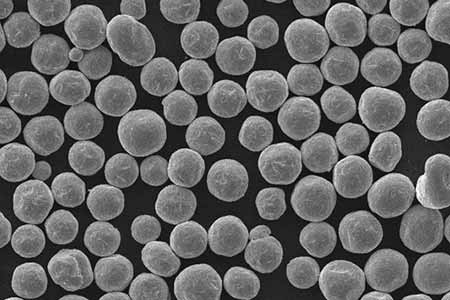

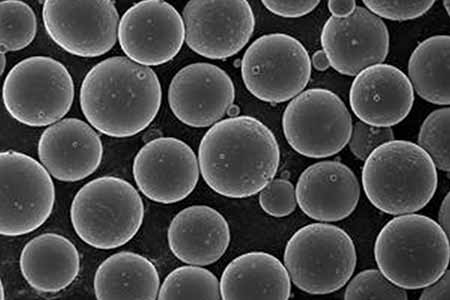

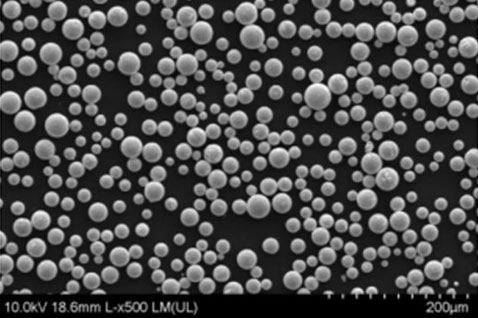

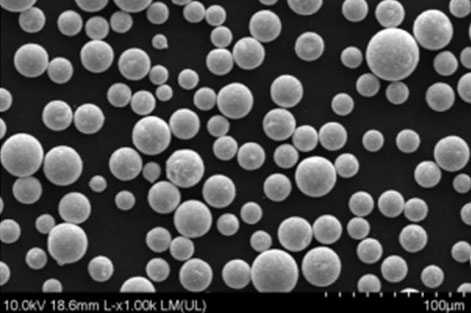

Spherical Tungsten Powder

Physical Properties

| Size | 15-53 um | ||||

| Apparet density | 10.51 g/cm3 | ||||

| Tap density | 12.46 g/cm3 | ||||

| Hall flow rate | 5.82 s/50g |

Chemical Composition

| Chemical Composition - by ICP-AES | ||||||||

| Element | W | Al | Si | Mg | Mn | Ni | As | Pb |

| Value (%) | ≥99.9 | <0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Sn | Sb | Cu | Ca | Mo | K+Na | ||

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | ||

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

| Value (%) | 0.002 | 0.001 | 0.015 | 0.003 | ||||

Features

- High purity;

- High Melting point.

Tungsten Powder Application

- Automotive;

- Medical instruments;

- Metal injection molding (MIM)

- Additive manufacturing (AM);

- Thermal spray (TSA).

Packing of Tungsten Powder

Related Powders of Tungsten Powder

| Tantalum Powder | |||

| More Powder |

Related Products of Tungsten Powder

|

|

Ceramic Sputtering Targets Tungsten Oxide Sputtering Target |

|

|

Evaporation Materials Tungsten Evaporation Pellet |

Crucibles Tungsten Crucible |

Metal Powders Tungsten Powder |

Click to download datasheet about Tungsten Powder

Click to download datasheet about Tungsten Powder

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).