Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

| Material Type | Nickel |

| Symbol | Ni |

| Atomic Weight | 58.6934 |

| Atomic Number | 28 |

| Color/Appearance | Lustrous, Metallic, Silvery Tinge |

| Thermal Conductivity | 91 W/m.K |

| Melting Point (°C) | 1,453 |

| Coefficient of Thermal Expansion | 13.4 x 10-6/K |

| Theoretical Density (g/cc) | 8.91 |

| Ferromagnetic | Magnetic Material |

| Z Ratio | 0.331 |

| Sputter | DC |

|

Max Power Density* (Watts/Square Inch) |

50 |

| Comments | Alloys with W/Ta/Mo. Smooth adherent films. |

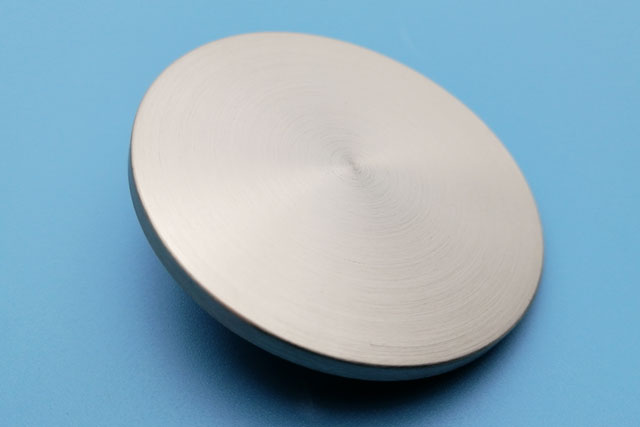

Nickel Sputtering Targets

Purity: 99.9%, 99.95%, 99.99%, 99.995%, 99.999%;

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm;

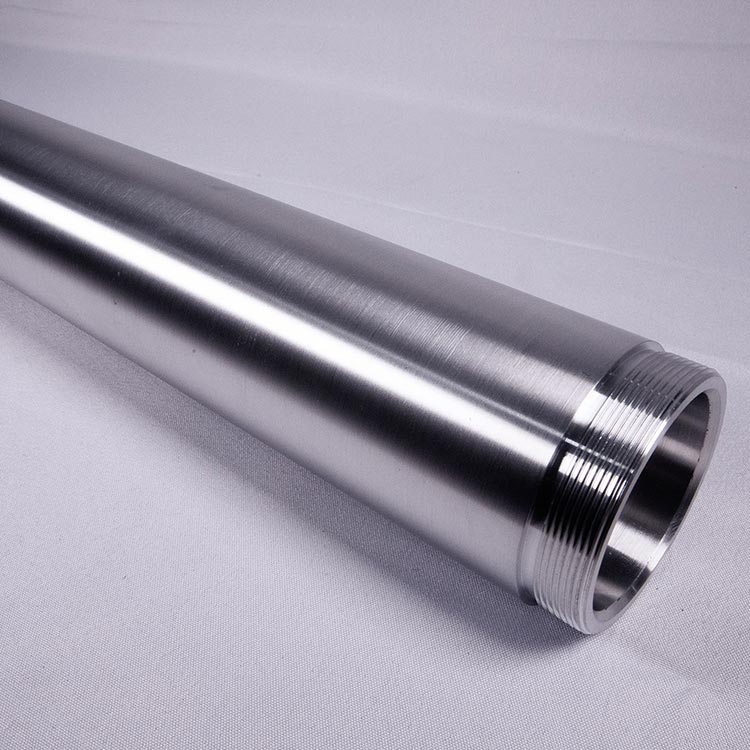

Targets Type: Planar sputtering target, Rotary sputtering target.

We can provide Nickel Sputtering Targets (Ni) of other shapes or sizes according to your needs. Please contact us if there is a need.

We can also provide Nickel rods, Nickel flakes, Nickel particles, Nickel blocks, Nickel powder, etc.

Cutting-edge Quality: Utilizing state-of-the-art manufacturing technologies, we are committed to delivering high-quality Nickel sputtering targets. Our rigorous testing processes ensure that our targets not only meet but exceed industry standards.

Customer Satisfaction and Trust: With years of dedicated effort, we have earned the trust of countless customers, including being the chosen supplier for Stanford University. Our professional team is dedicated to providing top-notch services, building long-term relationships based on satisfaction and trust.

Global Impact and Accessibility: Serving clients globally, our efficient distribution network ensures prompt deliveries. Wherever you are, accessing our high-quality Nickel sputtering targets is seamless. We provide comprehensive support and guidance throughout the purchasing process, ensuring a seamless experience for our global clientele.

Expert Technical Team: With over a decade of industry experience, our technical team can provide tailored advice based on your specific needs.

The nickel target blank prepared in this way not only has a uniform internal structure, but also has the advantage of fine grains, with an average particle size of <100um.

Nickel sputtering targets will undergo inspection by the quality and technical supervision department to ensure that the product quality complies with the specified standards or the terms outlined in the purchase order (contract).

| Items | Test Methods |

|---|---|

| Ingredient | Chemical Titration |

| Purity | ICP |

| Relative Density | Archimedes Drainage Method |

| Size | Vernier Caliper |

| Weight | High Precision Balance |

| Fit Position | Caliper |

| Fit Rate | Ultrasonic Testing |

| Bend | Feeler Gauge |

| Fitting Gap | Vernier Caliper |

ICP analyzer

Laser particle size analyzer

Ultrasonic flaw detector

Powder tester

Nitrogen adsorption instrument

We offer target bonding on backing plates using indium-, elastomer-, aluminum- and silver-based metallic alloy to improve thermal conductivity under high power inputs. Durable target bonding requires a variety of pre and post bond functions to assure adhesion.

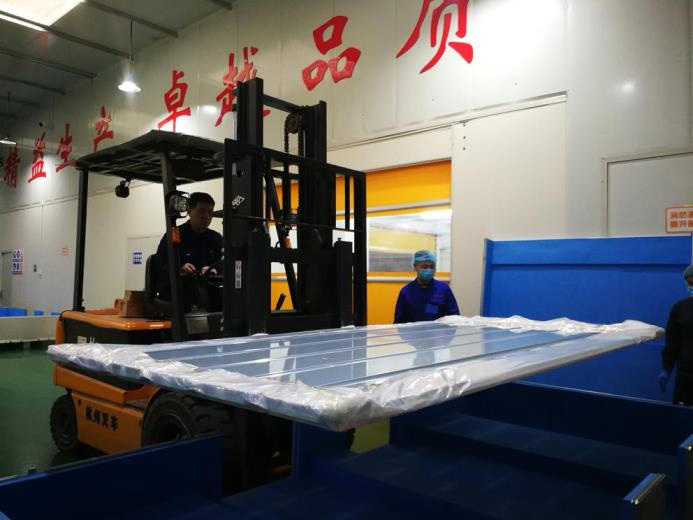

The picture only show packaging.

The product is vacuum sealed in an anti-static plastic bag and placed in a collision-proof packaging box.

Each product is attached with a label, indicating: product name, purity, specifications, net weight, batch number, production date, supplier name, manufacturer address During the transportation of the product, prevent bumps and scratches, prevent the product from being damaged and contaminated, and ensure that the target material is intact during transportation.

The product will be stored in a clean and dry environment.

| Pure Metal Sputtering Targets | |

| Alloy Sputtering Targets | |

| Ceramic Sputtering Targets | |

| Evaporation Materials | |

| Crucibles |

|

| Metal Powders |

Whether seeking Nickel targets for specific research endeavors or evaluating their market potential, this comprehensive guide offers invaluable insights to guide informed decision-making.

Nickel sputtering targets are raw materials used in Physical Vapor Deposition (PVD) processes to create thin films. Nickel is a silvery-white lustrous metal with a slight golden tinge. It is widely used in the production of sponge nickel and decorative coatings. Nickel can form a decorative coating on ceramic surfaces or a solder layer in circuit device fabrication when evaporated in a vacuum. It is often sputtered to create layers in magnetic storage media, fuel cells, and sensors. AEM offers nickel sputtering targets with high-purity and fine grain. Under the same conditions, the coating film is more uniform than similar products, and the coating area is increased by 10% to 20%.

Density: Nickel exhibits a density of approximately 8.91 grams per cubic centimeter, contributing to its overall mass.

Melting Point: The melting point of nickel is relatively high, standing at around 1,455 degrees Celsius, making it suitable for high-temperature applications.

Hardness: Nickel possesses a notable hardness, contributing to its durability and resistance to wear.

Conductivity: As a metal, nickel demonstrates excellent electrical conductivity, making it applicable in various electronic and conductive applications.

Malleability: Nickel is malleable, allowing it to be shaped and molded without breaking, enhancing its versatility in manufacturing processes.

Corrosion Resistance: Nickel is known for its corrosion-resistant properties, making it suitable for applications where exposure to corrosive environments is a concern.

Purity: High-purity nickel targets are often used in sputtering applications, ensuring minimal impurities for precise thin-film deposition.

Compatibility: Nickel is compatible with a range of materials, contributing to its widespread use in various industrial processes.

Oxidation resistance: Nickel has antioxidant properties. A dense oxide film will form on the surface of nickel in humid air at room temperature, preventing the metal from continuing to oxidize, which is beneficial to long-term use.

These characteristics make nickel sputtering targets well-suited for applications in thin-film deposition, electronics, and surface coating processes.

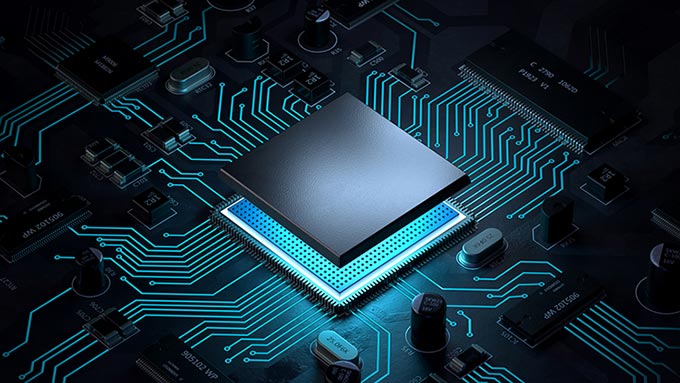

Thin-Film Deposition: Nickel sputtering targets are widely employed in physical vapor deposition (PVD) processes for the deposition of thin films on substrates. These thin films find applications in electronic and optical devices.

Electronics Manufacturing: Nickel thin films are utilized in the production of electronic components, such as integrated circuits, transistors, and resistors. The sputtering process allows for precise deposition on semiconductor wafers.

Magnetic Storage Devices: Nickel is crucial in the production of magnetic storage media, including hard disk drives. Thin films of nickel are deposited to create magnetic layers used in data storage.

Optical Coatings: Nickel sputtering targets contribute to the fabrication of optical coatings on lenses, mirrors, and other optical components. The deposited thin films enhance reflectivity and optical performance.

Solar Cells: Nickel is employed in the manufacturing of photovoltaic cells for solar energy applications. Thin films of nickel may serve as conductive layers or contacts in solar cell structures.

Surface Protection: Nickel coatings are used to enhance the corrosion resistance of materials. Nickel sputtered onto surfaces provides a protective layer, preventing degradation in harsh environments.

Aerospace and Automotive: Nickel thin films are utilized in the aerospace and automotive industries for applications such as sensors, coatings, and electronic components due to their conductivity and durability.

Decorative Coatings: Nickel can be sputtered onto various substrates for decorative purposes, providing a lustrous and corrosion-resistant finish in applications like jewelry and consumer electronics.

Research and Development: Nickel sputtering targets are essential in R&D activities, enabling scientists and engineers to explore new materials, study thin-film properties, and develop innovative technologies.

The versatile properties of nickel make it a valuable material in a range of industries, and its applications continue to expand with advancements in materials science and technology.

Choosing the right supplier for Nickel sputtering targets is an essential decision that significantly impacts thin-film deposition processes' success. To make an informed choice, consider these critical factors:

Experience: Opt for suppliers with a proven history and extensive expertise in providingNickel sputtering targets. Long-standing experience often assures high-quality products and services.

Certifications: Look for suppliers adhering to recognized quality standards like ISO or ASTM certifications. These affirm thatNickel sputtering targets meet industry benchmarks for quality and performance.

Product Diversity: Choose suppliers offering a wide range of Nickel compositions, finishes, and sizes. This variety enables selecting targets best suited for specific thin-film deposition needs.

Transparent Pricing: Ensure transparent and clear pricing without hidden charges. Clarity in pricing aids effective budgeting and minimizes unexpected costs.

Customer Feedback: Assess customer reviews to gauge both target quality and supplier service reliability.

Supply Chain: Evaluate the supplier's relationships with raw material providers to ensure a robust supply chain, crucial for target quality and consistency.

Customer Service: Consider the supplier's responsiveness and professionalism in handling inquiries and issues.

Timely Deliveries: On-time deliveries are vital for project timelines. Verify the supplier's delivery capabilities and track record.

Customization: Confirm the supplier's capability for customizing Nickel sputtering targets as per unique requirements.

After-Sales Support: Review post-purchase policies like warranties and return procedures for reliable support.

Careful consideration of these factors enables confidently selecting a Nickel sputtering target supplier aligned with thin-film deposition project needs, ensuring a successful procurement process.

AEM is a distinguished manufacturer and reliable source of high quality Nickel sputtering targets. Our comprehensive services ensure precision at every stage from initial selection to timely delivery, making AEM the first choice for quality Nickel sputtering targets requirements. Additionally, in most cases we have the flexibility to create custom samples based on your exact specifications. This ensures you get the exact Nickel sputtering target you need for your specific project. Trust AEM to meet your Nickel sputtering target needs with excellence and customization.

Nickel targets have excellent thermal conductivity and mechanical strength, and can maintain stability in high temperature and high pressure environments.

Nickel targets are typically of high purity, with varying levels of purity available based on customer demand, often as high as 99.9% or higher.

We offer a wide range of Nickel targets in various sizes and shapes, which can be customized to specific sizes and shapes according to customers' needs, such as round, square or other special shapes.

Nickel has excellent corrosion resistance and is suitable for various corrosive environments to ensure the stability and durability of the target during use.

Nickel targets are widely used in optical coatings, semiconductor manufacturing, infrared imaging and solar cells, and are key materials for the preparation of thin films and optical devices.

Nickel targets are widely used in fuel cells, semiconductors, optical coatings, LEDs, photovoltaics and other high-tech fields and are favored for their high corrosion resistance and stability.

We have a strict quality control process to ensure that our products meet the standards. Meanwhile, we provide perfect after-sales service to ensure customer satisfaction.