Bismuth Antimony Telluride Sputtering Targets (Bi0.5Sb1.5Te3)

| Material Type | Bismuth Antimony Telluride |

| Symbol | BixSb(2-x)Te3 |

| Color/Appearance | Grey, Solid |

| Melting Point (°C) | N/A |

| Theoretical Density (g/cc) | N/A |

| Water Solubility | Insoluble |

| Sputter | RF, RF-R, DC |

| Type of Bond | Indium, Elastomer |

| Comments |

Bismuth Antimony Telluride Sputtering Targets

Crystals of bismuth antimonides are synthesized by melting bismuth and antimony together under inert gas or vacuum. Zone melting is used to decrease the concentration of impurities. While synthesizing single crystals of bismuth antimonides, impurities must be removed from the samples, as oxidation occurring at the impurities leads to polycrystalline growth.

Bismuth Antimony Telluride Sputtering Targets Information

Bismuth Antimony Sputtering Targets

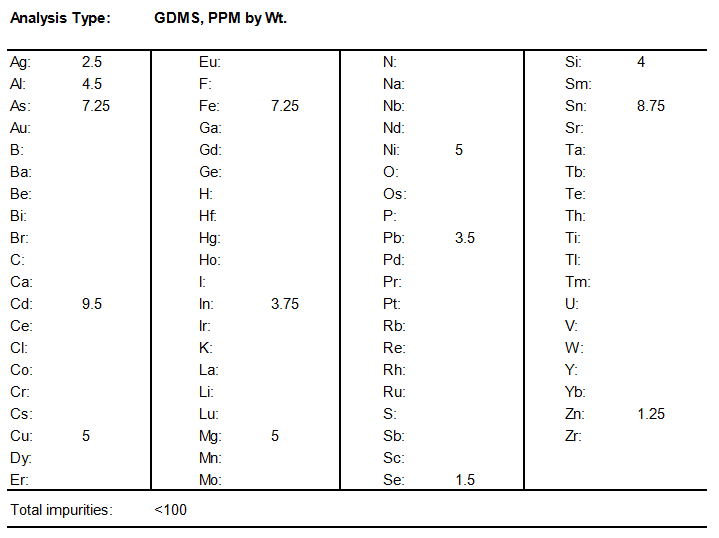

Purity: 99.99%;

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm.

Certificate of Analysis (COA) for 99.99% Purity Bi0.5Sb1.5Te3 Sputtering Target:

More Information on Bismuth Antimony Telluride Sputtering Targets

Applications• Semiconductor• Chemical Vapor Deposition (CVD) • Physical Vapor Deposition (PVD) |

Features• Competitive pricing• High purity • Grain refined, Engineered microstructure • Semiconductor grade |

Manufacturing Process

• Refining |

Options

• 99.99% minimum purity

• Smaller sizes also available for R&D applications

• Sputtering target bonding service

|

Related Products of Bismuth Antimony Telluride Sputtering Targets

|

Pure Metal Sputtering Targets |

|

Ceramic Sputtering Targets |

|

Evaporation Materials |

Crucibles N/A |

Metal Powders N/A |

Click to download datasheet about Bismuth Antimony Telluride Sputtering Targets (Bi0.5Sb1.5Te3)

Click to download datasheet about Bismuth Antimony Telluride Sputtering Targets (Bi0.5Sb1.5Te3)

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).