+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Semiconductor Sputtering Targets

views, Updated: 2021-09-24

Sputtering targets must meet stricter standards for high-quality ever to produce sub-micron scale and wafer targets in ever-larger sizes.

- Low particle

- Good film uniformity

- High usage efficiency

Features of Semiconductor Sputtering Targets

- Low-particle targets

- ULVAC has developed sputtering targets that suppress the generation of particles that can be the source of problems in the sputtering process.

- Gaseous elements are one factor in causing particle emissions, especially in aluminum targets. We are working to lower emissions by utilizing a vacuum melting method for refining and ingot purification processes.

- Attaining high uniformity by adjusting the metal microstructure

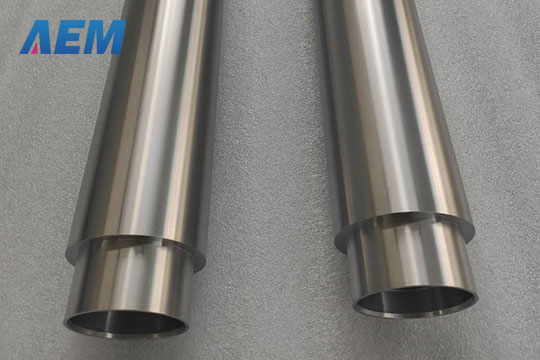

- ULVAC uses manufacturing processes that ensure high uniformity and a fine metal microstructure in most of its targets for semiconductor products, including high purity cobalt targets and titanium targets.

- Utilizing a fine metal microstructure with a high degree of uniformity allows uniform magnetic flux leakage on the target surface of high purity cobalt targets.

- Meticulous quality control system

- Integrated process manufacturing at ULVAC takes product characteristics and contours into account during production. Sophisticated analysis/evaluation system such as the GD-MS (glow discharge mass spectrometer) ensures purity and a high level of quality.

Sputtering Targets for Semiconductors

| Application Field | Materials | Manufacturing Method | Purpose of Use |

| Electrode Materials | W (5N) | Powder sintering | Gate area |

| Co(5N) | Melting method | Gate area | |

| Ni(5N) | Melting method | Gate area | |

| Ti(5N) | Melting method | Lynear, Barrier etc. | |

| Various silicide(4N up) | Powder sintering | ||

| Wiring Materials | Al(5N, 5N5) & Al alloy such as AlCu(5N, 5N5) | Vacuum melting method | Inter conect |

| Cu(6N) | Melting method | Inter conect | |

| Compound Semiconductor Materials | Au, Au alloy(4N) | Melting method | Wiring |

| WSi(5N) | Powder sintering | Electrode | |

| SiO2(4N,6N) | Artificial/ natural quartz | Insulating material | |

| Mounting & Wiring | Al(5N, 5N5)& Al alloy(5N, 5N5) | Vacuum melting method | Wiring |

| Cu(4N) | Melting method | Wiring | |

| Cr(3N) | Powder sintering | Barriers | |

| Precious metal materials | Melting method | Wiring | |

| TiW(4N up) | Powder sintering | Barriers | |

| Ni(4N) | Melting method | Barriers | |

| Capacitor Materials | BST | Powder sintering | DRAM/thin film capacitors |

| PZT | Powder sintering | FeRAM | |

| Barrier Materials | Ti(4N5) | Melting method | |

| TiW(4N up) | Powder sintering |

Target Material for Mainstream 300mm Wafers

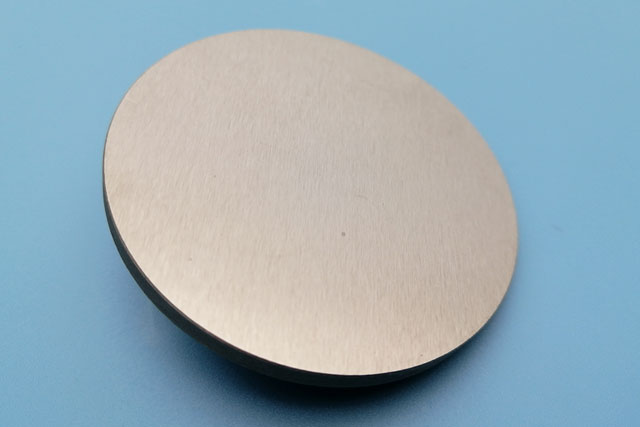

| Target Material | Al-0.5mass%Cu | Ti | Cu | Ta | W |

| Purity | 5N5up (Low-U, Th specifications) | 4N5up | 6Nup | 6Nup (Except for Nb and W) | 5N |

| Backing Plate Material | Aluminum or copper alloy | Aluminum alloy | Aluminum alloy | Aluminum or copper alloy |

Aluminum alloy or copper alloy |

| Bonding Method |

Electron beam welding, integrated part structure, or metal bonding |

Diffusion bonding | Diffusion bonding | Diffusion bonding | Metal bonding |

LATEST NEWS